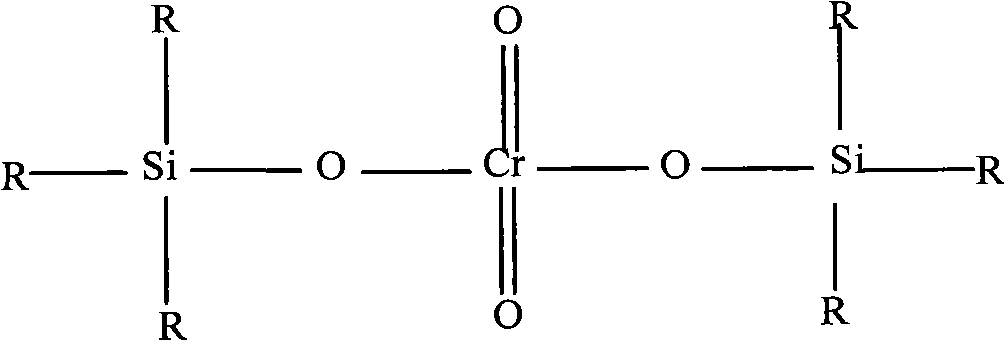

Olefin polymerizing catalyst, preparation and use thereof

A technology of olefin polymerization and catalyst, which is applied in the field of improved supported chromium-based catalysts, which can solve the problems of temperature sensitivity and low catalytic efficiency, and achieve the effects of good polymer shape, high bulk density and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

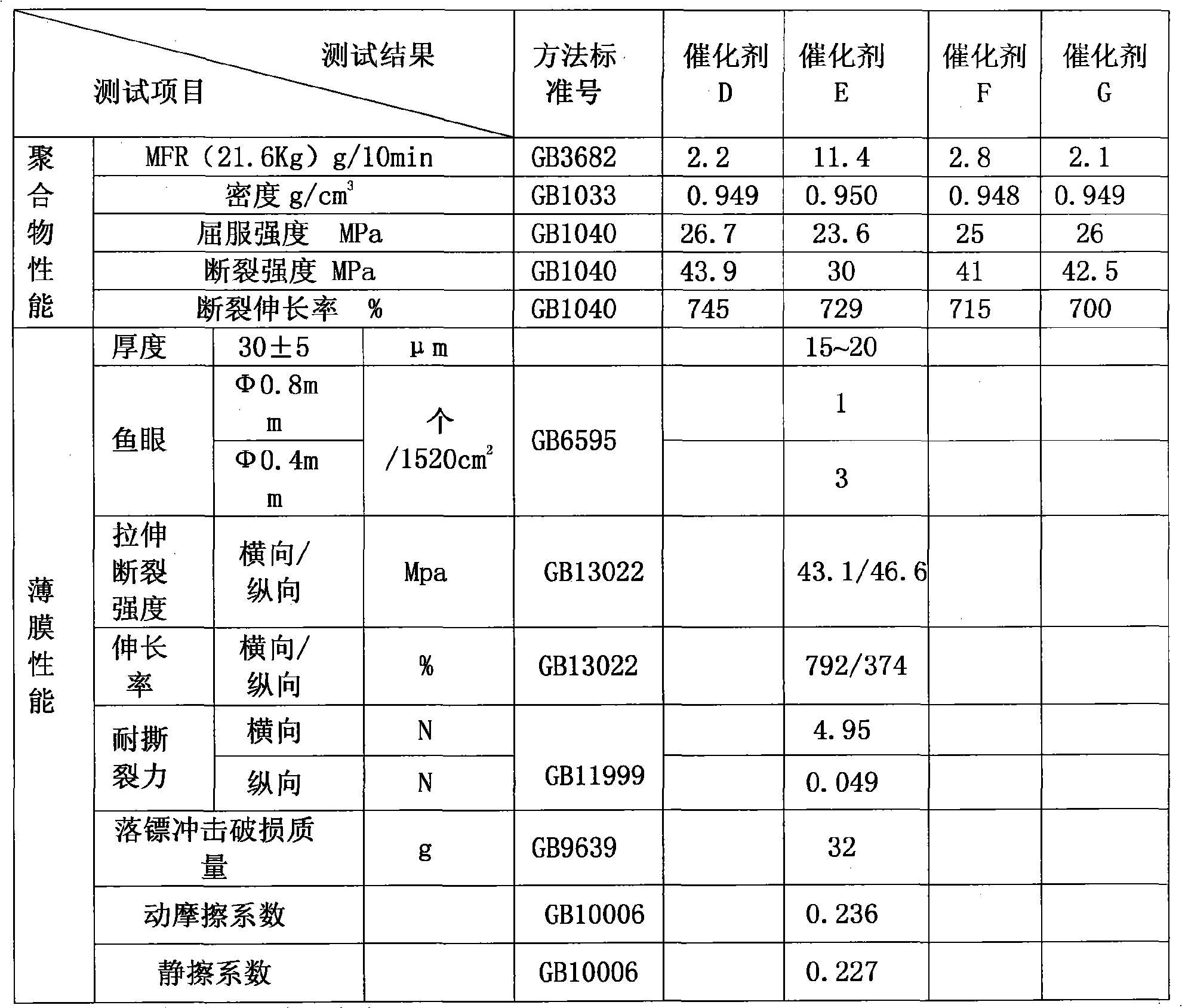

Examples

Embodiment 1

[0028] Composite carrier A described in the present invention was prepared.

[0029] Mix 200g AlCl with stirring 3 ·6H 2 O was dissolved in 1000mL deionized water, and 1900g SiO was added 2 The carrier is impregnated at 30-50°C for 2 hours, heated up to 100°C to evaporate free water in the system, and fully dried to obtain SiO with good flow. 2 / AlCl 3 Composite carrier, under nitrogen protection, activated the obtained composite carrier in a muffle furnace for 12 hours at 600°C, took it out and cooled it to normal temperature under nitrogen protection, and obtained composite catalyst carrier A.

Embodiment 2

[0031] Composite carrier B of the present invention was prepared.

[0032] 400g AlCl 3 ·6H 2 O was dissolved in 1000mL deionized water, and 1800g SiO was added 2 The carrier is impregnated at 30-50°C for 2 hours, heated up to 100°C to evaporate free water in the system, and fully dried to obtain SiO with good flow. 2 / AlCl 3 Composite carrier, under the protection of nitrogen, activated the obtained composite carrier in a muffle furnace for 12 hours at 600°C, took it out and cooled it to normal temperature under the protection of nitrogen, and obtained the composite catalyst carrier B.

Embodiment 3

[0034] Prepare composite carrier C according to the present invention.

[0035] 400g of anhydrous AlCl 3 Dissolve in 1000mL deionized water, add 1600g SiO 2 The carrier is impregnated at 30-50°C for 2 hours, heated up to 100°C to evaporate free water in the system, and fully dried to obtain SiO with good flow. 2 / AlCl 3 Composite carrier, under nitrogen protection, activated the obtained composite carrier in a muffle furnace for 12 hours at 600° C., took it out and cooled it to normal temperature under nitrogen protection, and obtained composite catalyst carrier C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com