Supported metallocene catalyst and preparation method thereof

A technology of metallocene catalysts and metallocene compounds, applied in the field of olefin polymerization catalysts, can solve the problems of reducing the utilization rate of alkyl aluminoxanes and metallocene compounds, low catalytic activity of supported catalysts, and increasing the cost of supported catalysts, so as to reduce the carrier Possibility of aggregation, low loss, and high-efficiency preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

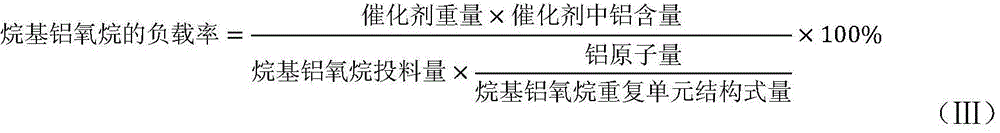

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: preparation supported catalyst

[0050] (1) Supported methyl aluminoxane:

[0051] Under nitrogen protection, add 10.5g of methylalumoxane and 50mL of toluene to a reaction flask with mechanical stirring, stir to dissolve and keep the temperature at 100°C; at the same time, add the above-mentioned treated carrier silica gel 15.2 to another reaction flask g, keep stirring, gradually add silica gel into the methyl aluminoxane solution, rinse the residual silica gel with 30ml toluene, then continue stirring at constant temperature for 3 hours, finally wash with toluene at 100°C, filter, and dry to obtain the loaded methyl Aluminoxane silica gel carrier 25.3g.

[0052] (2) Loaded metallocene compound:

[0053] Under nitrogen protection, weigh 64mg of dimethylsilyl bridged bis(2-methyl-4-phenyl-indenyl)zirconium dichloride and add it to a reaction flask with mechanical stirring, add 15ml of n-hexane and stir to form The slurry was kept at a temperature of 30...

Embodiment 2

[0054] Example 2: Use the supported catalyst obtained in Example 1 to carry out propylene polymerization.

[0055] Polymerization was carried out in a 5 L autoclave. The polymerization kettle was first purged and replaced with dry nitrogen, and 15 mmol of hydrogen was added to the reaction kettle, and 150 mg of supported metallocene catalyst was suspended in 5 ml of n-hexane to make a slurry and added to the catalyst feeder, and then 3.5 ml of 1 mol / L Tris Start stirring the isobutylaluminum hexane solution, pour the catalyst and triisobutylaluminum into the reactor with 2.3 L of liquid propylene, raise the temperature to 70° C. and react for 1 hour to obtain 352 g of powdery isotactic polypropylene. The polymerization activity was 2346 g / gcat·hr, and the melt index of the obtained polymer was 6.5 g / 10 min.

Embodiment 3

[0056] Example 3: Use the supported catalyst obtained in Example 1 to carry out propylene polymerization.

[0057] Polymerization was carried out in a 5 L autoclave. The polymerization kettle was first purged and replaced with dry nitrogen, and 12 mmol of hydrogen gas was added to the reaction kettle, and 152 mg of supported metallocene catalyst was suspended in 5 ml of n-hexane to make a slurry and added to the catalyst feeder, and then 3.5 ml of three Start stirring the isobutylaluminum hexane solution, pour the catalyst and triisobutylaluminum into the reactor with 2.3 L of liquid propylene, raise the temperature to 70° C. and react for 1 hour to obtain 260 g of powdery isotactic polypropylene. The polymerization activity was 1710 g / gcat·hr, and the melt index of the obtained polymer was 2.4 g / 10 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com