Ultrasonic wave vibration field slit flow small angle laser light scattering real time observation system

A technology of laser light scattering and real-time observation, applied in the measurement of scattering characteristics, etc., can solve the problems of attenuation, large loss, and inability to reflect the influence of vibration on the shape and structure of the melt, and achieve the effect of accelerating the relaxation process and enriching the theory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

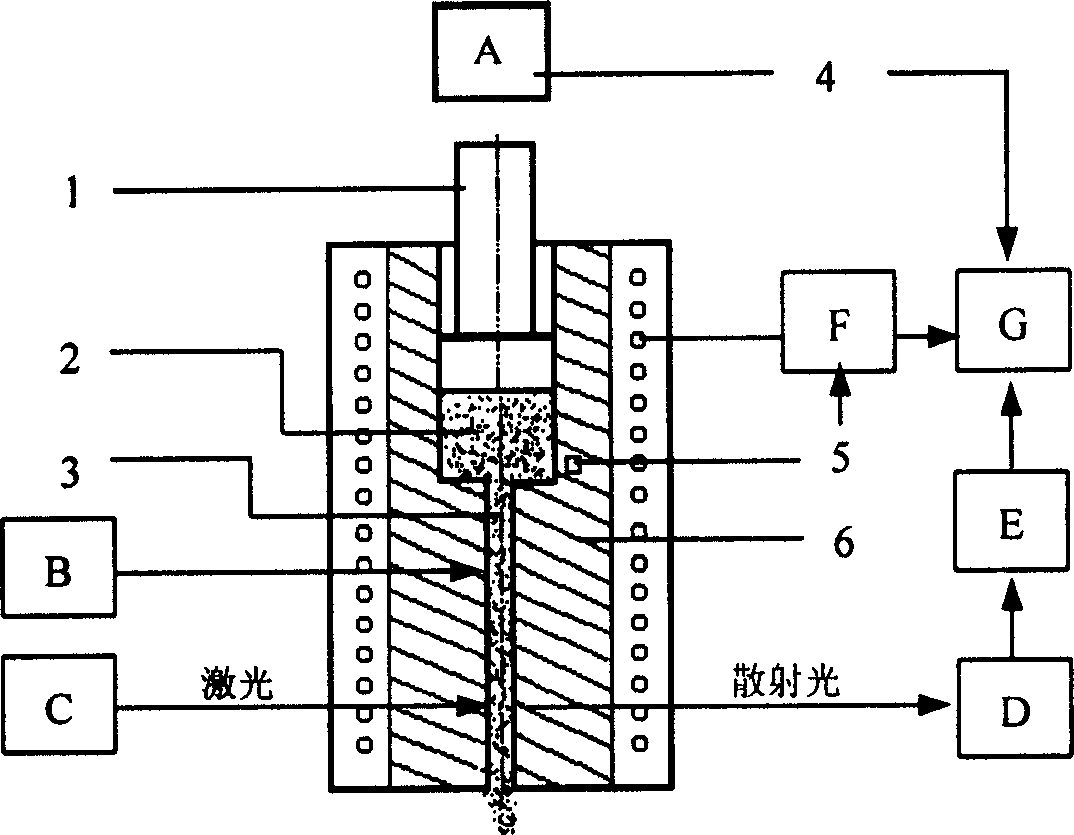

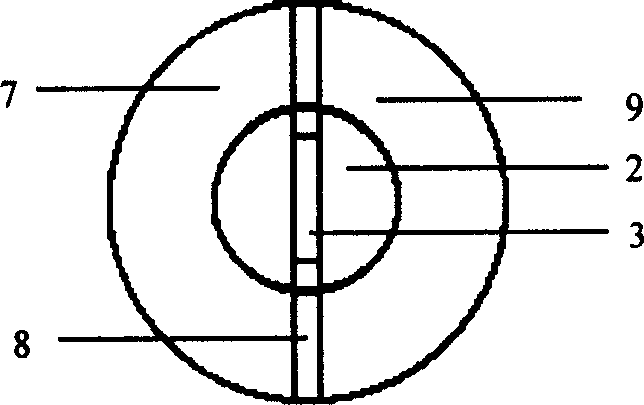

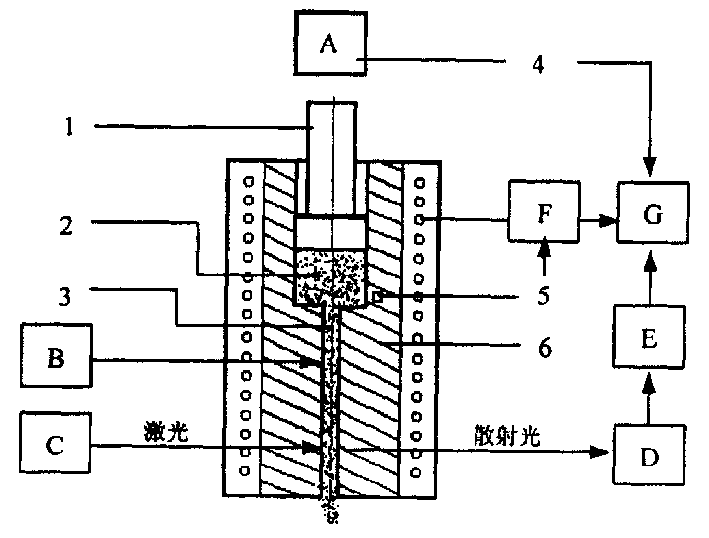

[0010] Such as figure 1 , figure 2 As shown, it includes: a mold 6 with a slit flow channel 3 on the lower part and a material cavity 2 on the upper part wound with a heating coil. The mold 6 is assembled from a left mold 7, an interlayer 8 and a right mold 9. The interlayer The thickness of 8 is consistent with the thickness of the slit flow channel 3, a temperature sensor 5 is installed on the outer surface of the bottom of the cavity 2, a plunger rod 1 is installed in the material storage cavity 2, and a clamp equipped with a displacement sensor 4 is installed above the plunger rod 1. The pressure control system A is equipped with an ultrasonic generator B and a laser C at the upper and lower parts perpendicular to the long side of the slit flow channel 3 of the mold 6, the laser C corresponds to the photodetector D, and the photodetector D is connected to The amplifier E, the heating coil and the temperature sensor are connected to the temperature control system F, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com