Microwave assisted molecular blotting magnetic microsphere preparation method and uses

A technology of magnetic microspheres and molecular imprinting, applied in the fields of material science and engineering and modern separation analysis, to achieve the effect of improving uniformity and stability, good dispersion, and shortening aging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention is a preparation method of microwave-assisted molecularly imprinted magnetic microspheres, comprising the following steps:

[0026] 1).Microwave heating chemical precipitation method to synthesize nano-Fe 3 o 4 Magnetic fluid, ultrasonic cleaning, magnetic field separation, magnetic fluid cleaning to neutral, redispersed in water;

[0027] 2). Mix the template molecules and functional monomers and shake them well, and place them at room temperature for 10-14 hours; add a crosslinking agent to the mixed solution, shake them well, and leave them at room temperature for 10-14 hours.

[0028] 3). The Fe obtained in step (1) 3 o 4 The magnetic fluid is stirred and mixed with water, anionic surfactant and stabilizer, and the ultrasonic dispersion time is not less than 30 minutes;

[0029] 4). Add the polymerization solvent and the magnetic fluid dispersed in the anionic surfactant and stabilizer in the step (3) to the reaction bottle in the microwave reactor...

Embodiment

[0039] This embodiment takes atrazine as an example to describe the present invention in detail, but this does not limit the protection scope of the present invention.

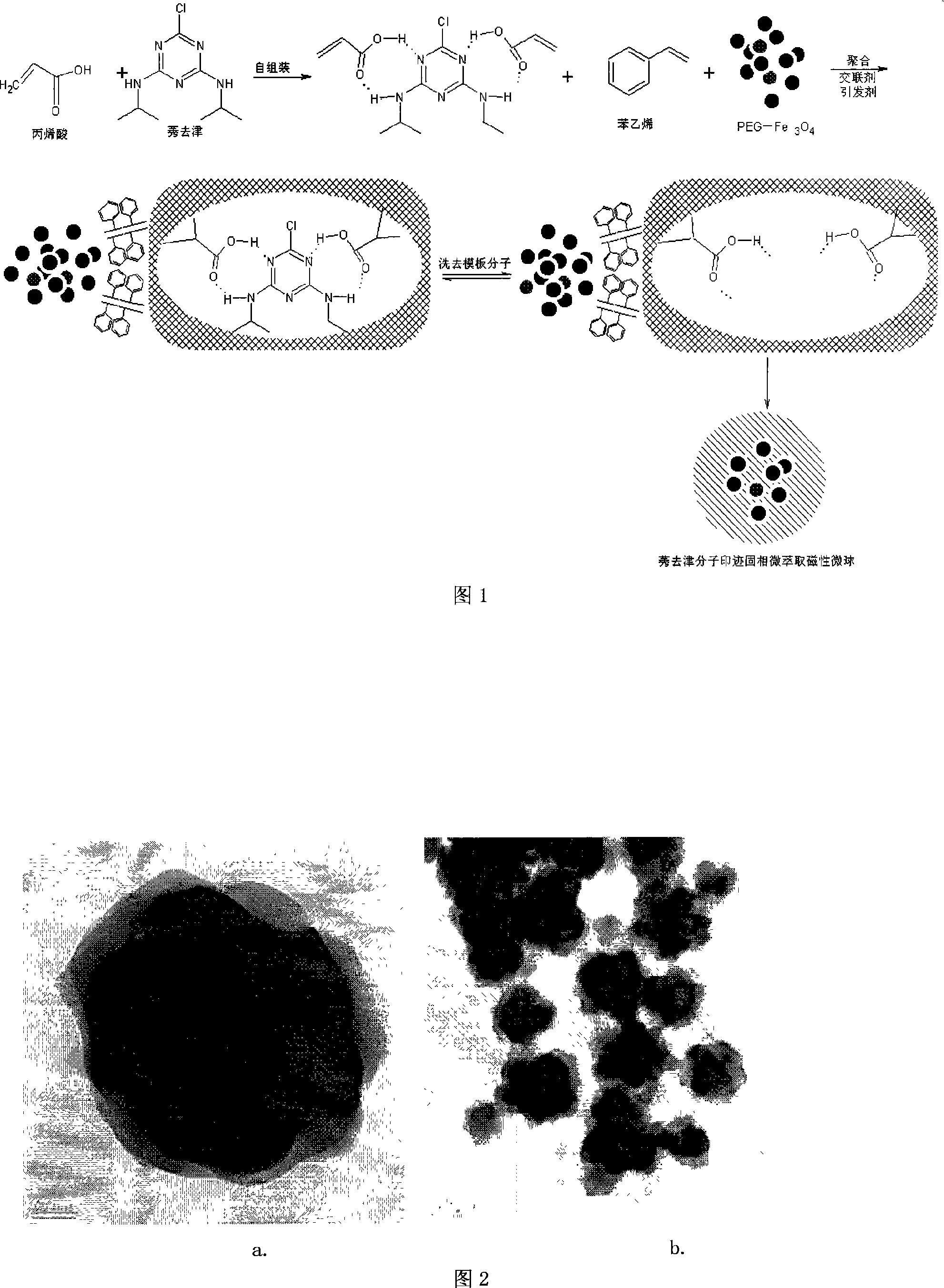

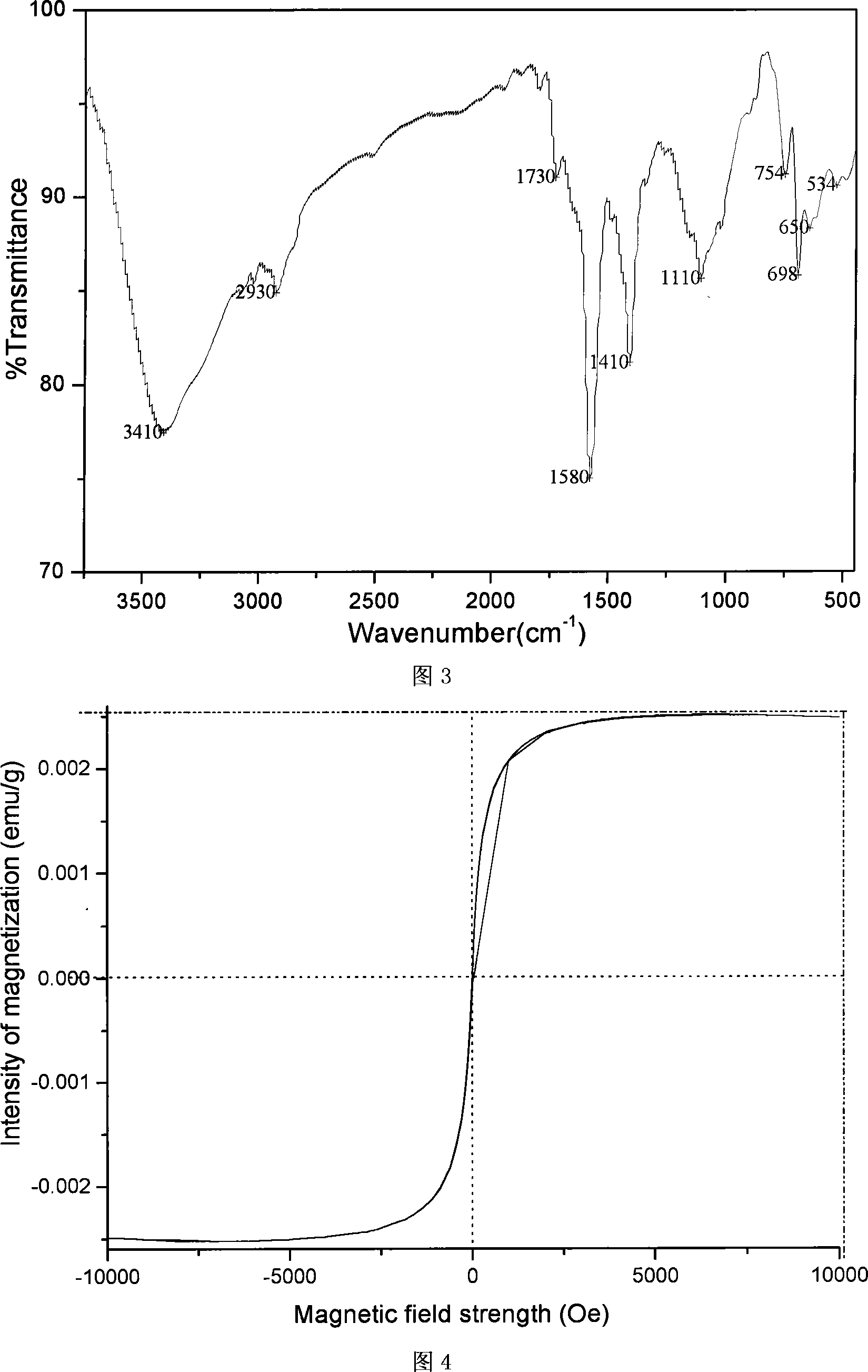

[0040] As shown in Figure 1, the preparation method of atrazine molecularly imprinted magnetic microspheres is as follows:

[0041] (1) Using a microwave chemical reactor, the microwave output power is continuously adjustable. Install a reaction flask with a mechanical stirrer (polytetrafluoroethylene stirring rod), a condenser tube, a liquid inlet and a vent in the microwave reactor, and add 20 mL of Fe 3+ : Fe 2+ A 2:1 mixed solution in 120mL distilled water, N 2 After 20 minutes, under 600r / min mechanical stirring, quickly add 28% NH with a balanced addition funnel 3 ·H 2 O.

[0042] (2) Preparation of nano-Fe 3 o 4 The reaction of the ferrofluid occurs until the end of aging, and the continuous feeding of N 2 Deoxygenate and maintain a stirring speed of 580-600r / min with high-speed mechanical stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com