Ultrasonic/filler combined sludge decrement device and process

A sludge reduction and ultrasonic technology, applied in the direction of sludge treatment, sludge treatment, biological sludge treatment, etc., can solve the problem of insignificant reduction effect, shorten the reaction time, increase the reduction speed, increase the ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) 30% of the sludge at the bottom of the sedimentation tank 4 of the mainstream biological treatment module is first pumped into the ultrasonic unit 5, and the hydraulic retention time of the ultrasonic unit is 20 minutes. The sound energy density range of the ultrasonic device is 0.5W / ml, and the operation mode is to run for 5s and stop for 5s to ensure the uniformity of the ultrasonic and the effect of cell lysis; the concentration of sludge entering the ultrasonic unit is 4.5g / L, and the initial sewage of the ultrasonic unit The amount of mud is 2L.

[0032] (2) Lead 200ml of the ultrasonically pretreated sludge into the anaerobic side flow tank (that is, the bioreduction unit) 6 equipped with SPR-1 suspended filler. The initial sludge volume of the anaerobic side flow tank 6 is 2L, and the filling rate is 15%. The rotational speed in the anaerobic side flow tank was controlled at 200 rpm. Suspended fillers are suspended and floating in the pool.

[0033] (3) Th...

Embodiment 2

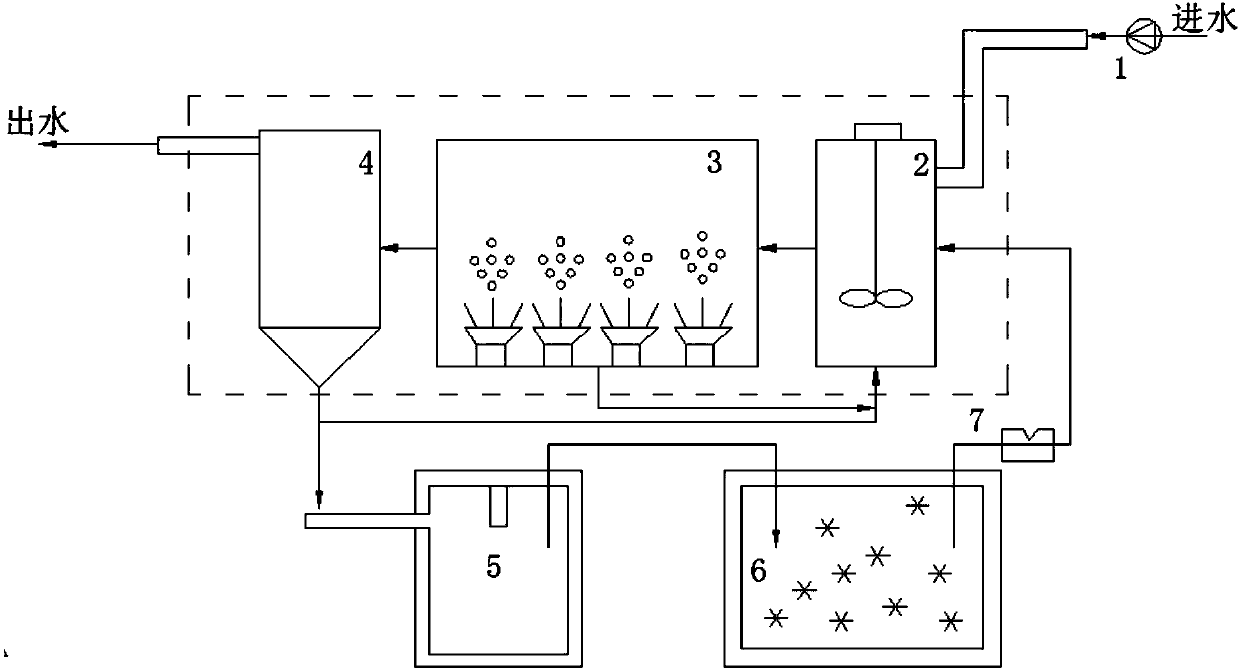

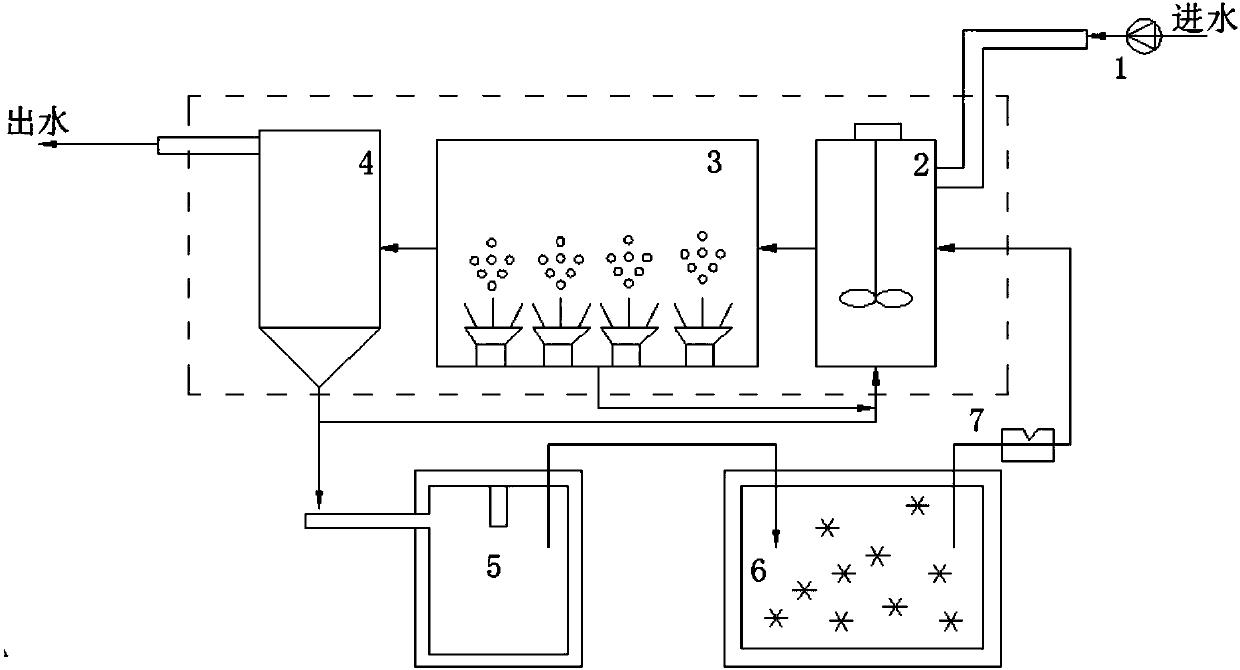

[0036] An ultrasonic packing combined sludge reduction process, such as figure 1 shown, including the following steps:

[0037] (1) The sewage to be treated is sent to the anoxic tank 2 and the aeration tank 3 successively through the water inlet pump 1 for treatment, and the mud-water mixture in the aeration tank 3 enters the sedimentation tank 4 after solid-liquid separation, and the sludge deposited at the bottom 5% is pumped into the ultrasonic unit 5, and the rest is all returned to the anoxic pool 2. The ultrasonic treatment process is: the hydraulic retention time is 0.5min, the sound energy density during ultrasonic treatment is 0.1W / m, and the operation mode is: ultrasonic 5s, stop 5s ;

[0038] (2) After the sludge is pretreated by the ultrasonic unit 5, it is sent to the bioreduction unit 6 for treatment, and finally sent back to the anoxic pool 2 by the metering pump 7. The bioreduction unit 6 includes the pool of the bioreduction unit 6 and the suspended filler ...

Embodiment 3

[0042] Except that the precipitation at the bottom of the sedimentation tank 4 in this embodiment is all pumped into the ultrasonic unit 5, the hydraulic retention time of the ultrasonic unit 5 is 20min, the sound energy density during ultrasonic treatment is 2W / m, the suspended filler is a German sponge filler, and the filling rate is 60%, the rotating speed of the rotating unit is 500rpm, the hydraulic retention time of the bioreduction unit 6 is 15 days, and the rest are the same as in Example 2.

[0043] After testing, the sludge weight reduction rate of this embodiment can reach 15.22%, and the organic matter weight reduction rate of the sludge can reach 18.97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com