Loaded metallocene catalyst and preparation method thereof

A technology of metallocene catalysts and metallocene compounds, applied in the field of olefin polymerization catalysts, can solve the problems of reducing the utilization rate of alkylaluminoxanes and metallocene compounds, increasing the cost of supported catalysts, and large loss of alkylaluminoxanes, etc., to achieve Low loss, high-efficiency preparation, and high loading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

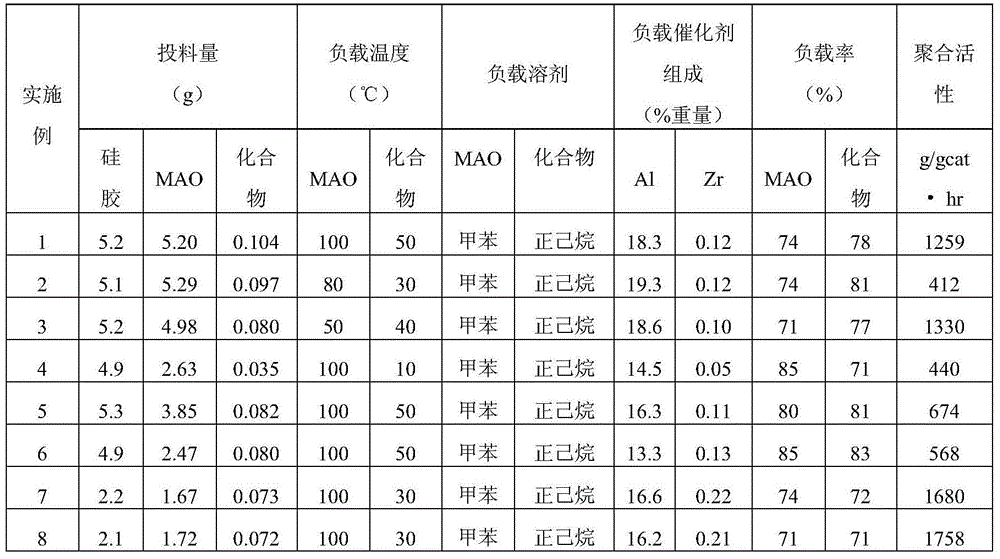

Examples

Embodiment 1

[0034] Carrier treatment: under dry nitrogen flow, heat the silica gel at 600°C for 6 hours; weigh 5.2g of the treated silica gel, add it to a glass reaction bottle with mechanical stirring, vacuumize, stir slowly and heat to 100°C , keep for 5 hours. Then nitrogen protection was introduced into the reaction bottle.

[0035] Loading methylaluminoxane: Add 20 mL of toluene to the treated silica gel carrier, heat to 100°C, and stir to form a suspension. At the same time, 5.2 g of methylalumoxane was added to another reaction flask, dissolved in 20 mL of toluene at room temperature, and then the methylalumoxane solution was added dropwise to the silica gel carrier suspension, stirred at constant temperature for 3 hours, and then stirred at 100 Wash with toluene at ℃, filter, and dry to obtain a silica gel carrier loaded with methylaluminoxane.

[0036] Loaded metallocene compound: Suspend the above-mentioned silica carrier loaded with aluminoxane in 20 mL of n-hexane, weigh 104...

Embodiment 2

[0039] Carrier treatment: under dry nitrogen flow, heat the silica gel at 600°C for 6 hours; weigh 5.1g of the treated silica gel, add it to a glass reaction bottle with mechanical stirring, vacuumize, stir slowly and heat to 80°C , keep for 5 hours. Then nitrogen protection was introduced into the reaction bottle.

[0040] Loading methylaluminoxane: Add 20 mL of toluene to the treated silica gel carrier, heat to 80°C, and stir to form a suspension.

[0041] At the same time, 5.29 g of methylalumoxane was added to another reaction flask, dissolved in 20 mL of toluene at room temperature, and then the methylalumoxane solution was added dropwise to the silica gel carrier suspension, stirred at constant temperature for 3 hours, and then stirred at 80 Wash with toluene at ℃, filter, and dry to obtain a silica gel carrier loaded with methylaluminoxane.

[0042] Loaded metallocene compound: Suspend the above-mentioned silica carrier loaded with aluminoxane in 20 mL of n-hexane, we...

Embodiment 3

[0045] Carrier treatment: under dry nitrogen flow, heat the silica gel at 600°C for 6 hours; weigh 5.2g of the treated silica gel, add it to a glass reaction bottle with mechanical stirring, vacuumize, stir slowly and heat to 50°C , keep for 5 hours. Then nitrogen protection was introduced into the reaction bottle.

[0046] Loading methylaluminoxane: Add 20 mL of toluene to the treated silica gel carrier, heat to 50°C, and stir to form a suspension. At the same time, 4.98 g of methylalumoxane was added to another reaction flask, dissolved in 20 mL of toluene at room temperature, then the methylalumoxane solution was added dropwise to the silica gel carrier suspension, stirred at constant temperature for 10 hours, and then stirred at 50 Wash with toluene at ℃, filter, and dry to obtain a silica gel carrier loaded with methylaluminoxane.

[0047] Loaded metallocene compound: Suspend the above-mentioned silica carrier loaded with aluminoxane in 20 mL of n-hexane, weigh 80 mg of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com