High-strength supramolecular hydrogel, as well as preparation method and application thereof

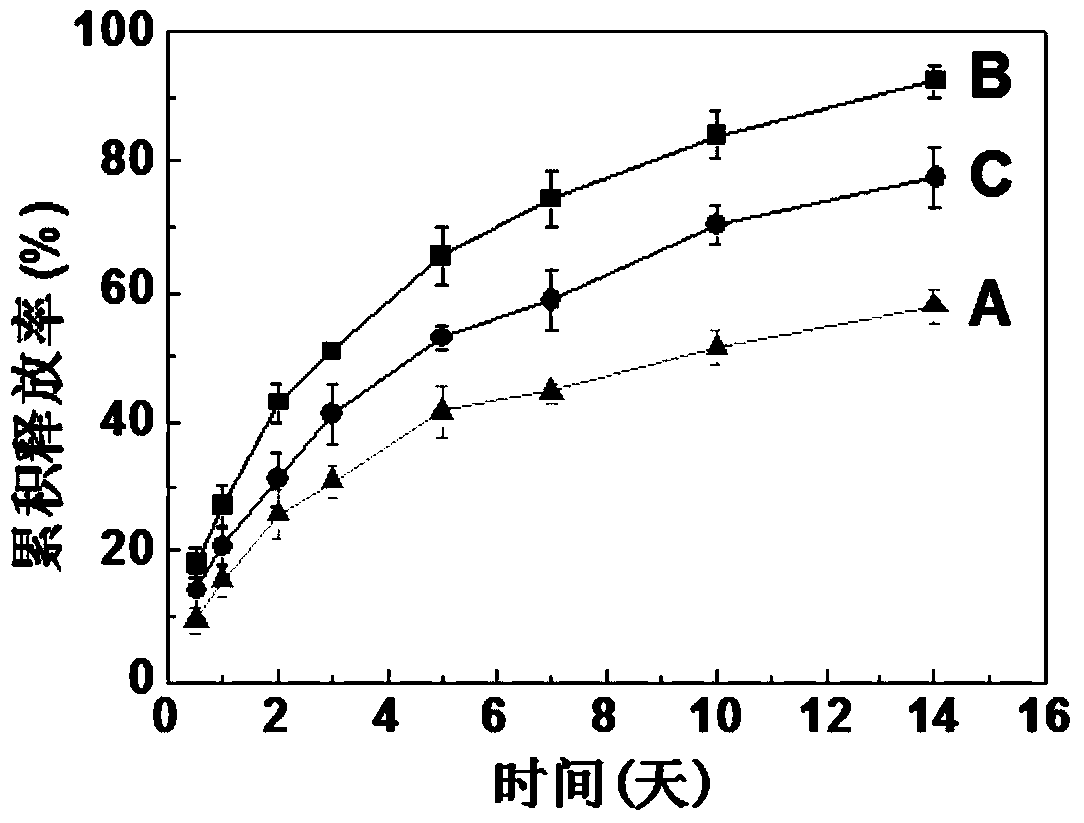

A supramolecular hydrogel, high-strength technology, applied in the field of biomedical materials, can solve the problems of difficult to meet the long-term sustained release of gene drugs, rapid degradation, etc., to increase degradability, maintain biological activity, and the preparation method is simple and fast. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

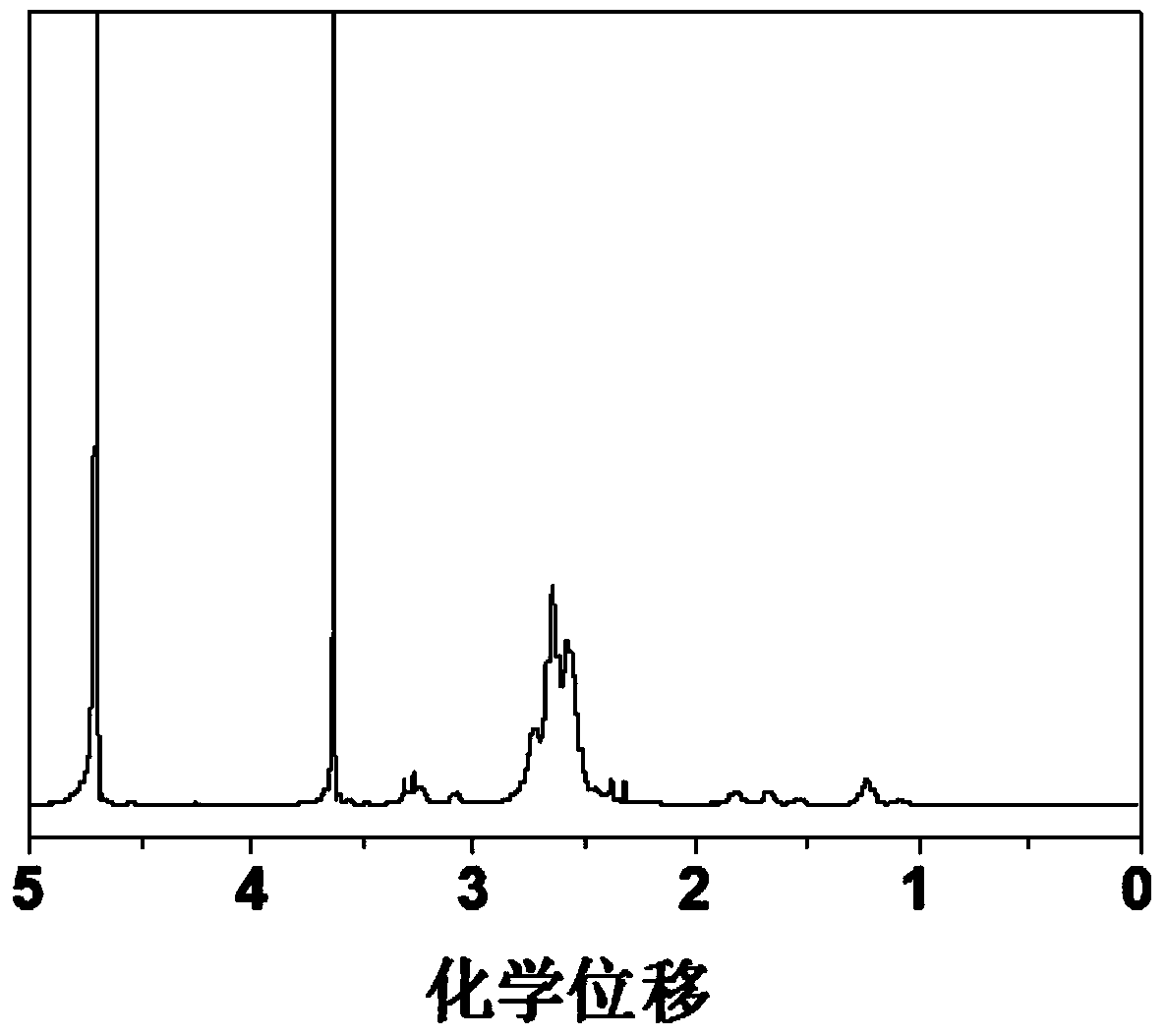

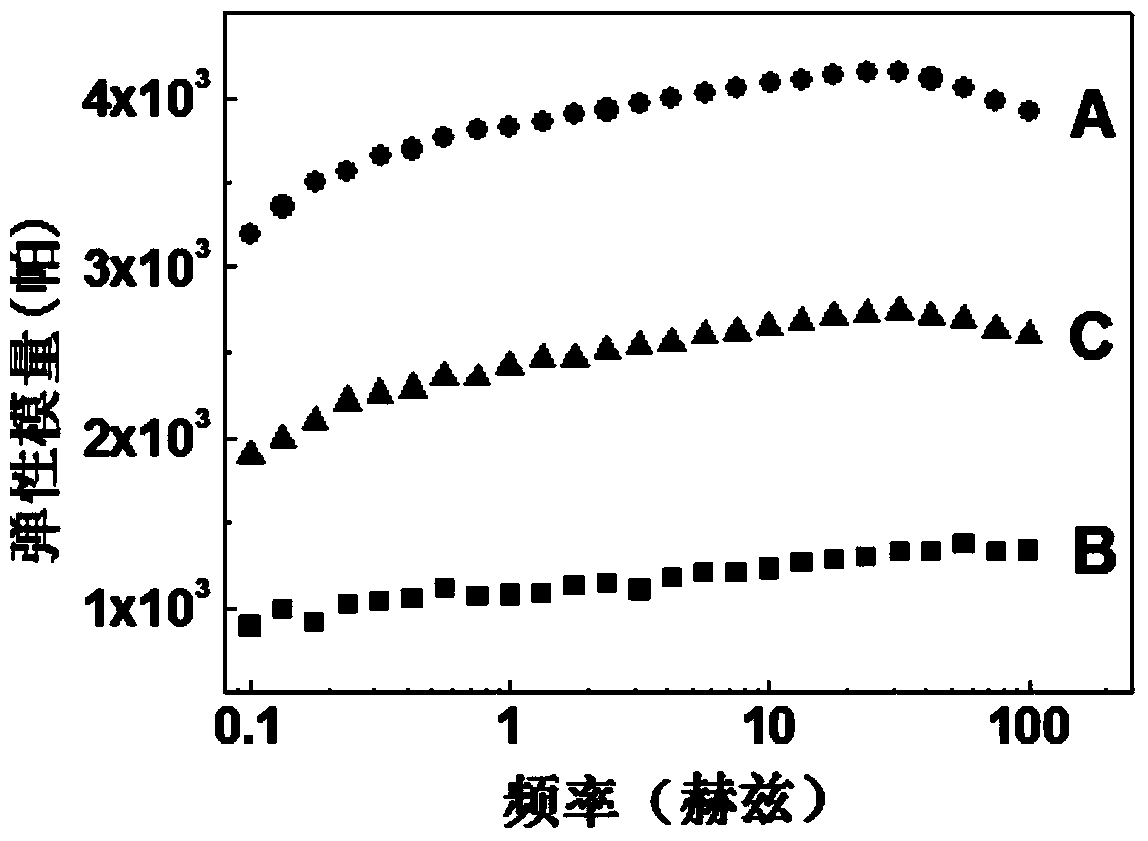

[0045] A preparation method of high-strength supramolecular hydrogel, comprising the following steps:

[0046] 1. Drying of polyethylene glycol: Dry the polyethylene glycol under vacuum at 60° C. for 24 hours.

[0047] 2. Drying of the caprolactone monomer: Distill the caprolactone monomer under reduced pressure at 90°C.

[0048] 3. Drying of dichloromethane and pyridine: Add calcium hydride powder into dichloromethane or pyridine solution (add 1-2 grams of calcium hydride per 500ml solution), stir at room temperature for 24 hours and then distill.

[0049] 4. Synthesis of polyethylene glycol-polycaprolactone-polycationic copolymer (corresponding to "step 1)" in the claims);

[0050] a. Synthesis of polyethylene glycol-polycaprolactone block polymer:

[0051] Add 15 grams of dry polyethylene glycol (weight average molecular weight 1900), 10 grams of caprolactone monomer, and 0.05 grams of stannous octoate into the reaction device at the same time, and use an oil pump to evac...

Embodiment 2

[0061] A preparation method of high-strength supramolecular hydrogel, comprising the following steps:

[0062] 1. Drying of polyethylene glycol: Dry the polyethylene glycol under vacuum at 60° C. for 24 hours.

[0063] 2. Drying of the caprolactone monomer: Distill the caprolactone monomer under reduced pressure at 90°C.

[0064] 3. Drying of dichloromethane and pyridine: Add calcium hydride powder into dichloromethane or pyridine solution (add 1-2 grams of calcium hydride per 500ml solution), stir at room temperature for 24 hours and then distill.

[0065] 4. Synthesis of polyethylene glycol-polycaprolactone-polycationic copolymer (corresponding to "step 1)" in the claims);

[0066] a. Synthesis of polyethylene glycol-polycaprolactone block polymer:

[0067] Add 15 grams of dry polyethylene glycol (weight average molecular weight 1900), 5 grams of caprolactone monomer, and 0.05 grams of stannous octoate into the reaction device at the same time, and use an oil pump to evacu...

Embodiment 3

[0077] A preparation method of high-strength supramolecular hydrogel, comprising the following steps:

[0078] 1. Drying of polyethylene glycol: Dry the polyethylene glycol under vacuum at 60° C. for 24 hours.

[0079] 2. Drying of the caprolactone monomer: Distill the caprolactone monomer under reduced pressure at 90°C.

[0080] 3. Drying of dichloromethane and pyridine: Add calcium hydride powder into dichloromethane or pyridine solution (add 1-2 grams of calcium hydride per 500ml solution), stir at room temperature for 24 hours and then distill.

[0081] 4. Synthesis of polyethylene glycol-polycaprolactone-polycationic copolymer (corresponding to "step 1)" in the claims);

[0082] a. Synthesis of polyethylene glycol-polycaprolactone block polymer:

[0083] Add 15 grams of dry polyethylene glycol (weight average molecular weight 5000), 10 grams of caprolactone monomer, and 0.05 grams of stannous octoate into the reaction device at the same time, and use an oil pump to evac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com