Nanofiber membrane, preparation method and application

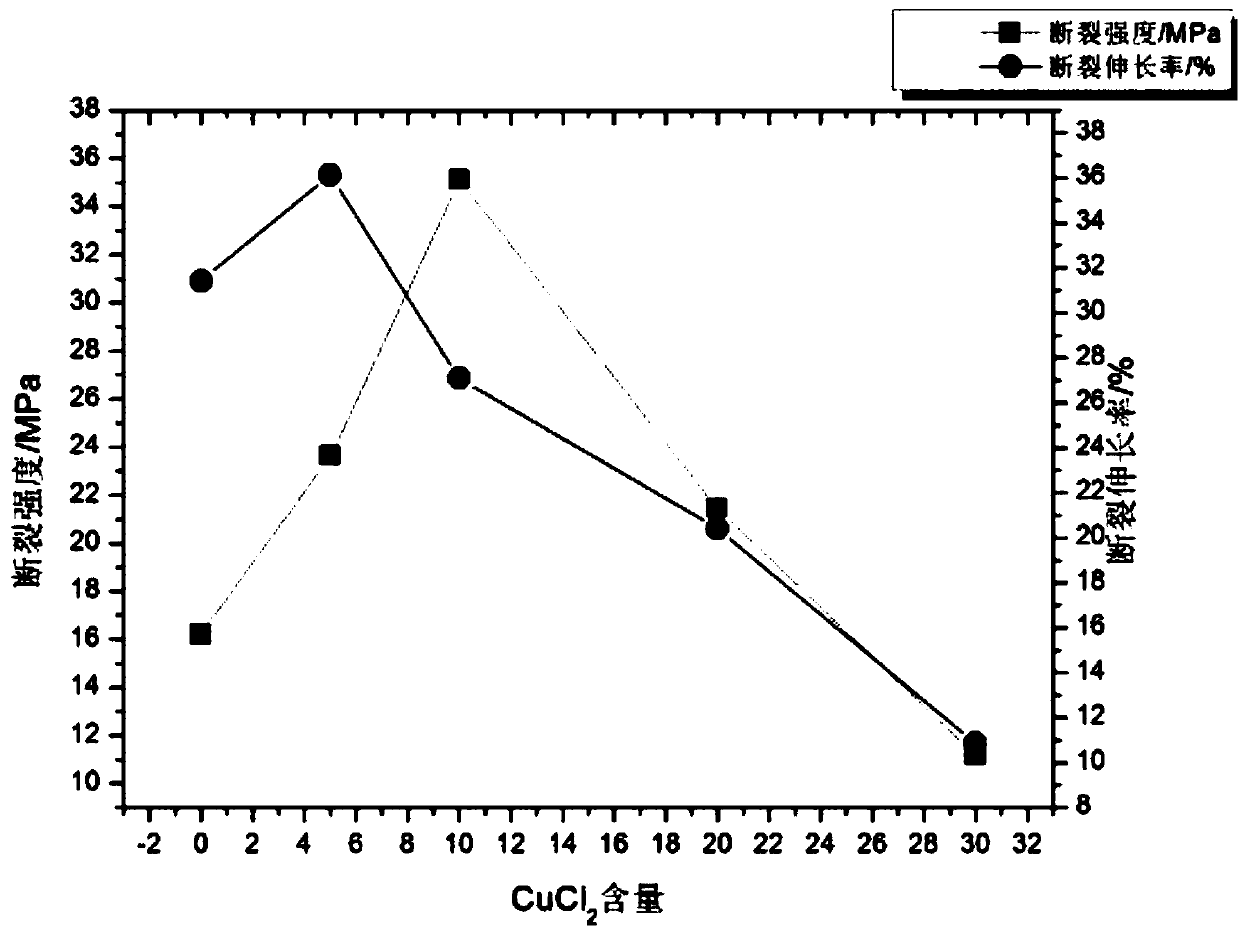

A nanofiber membrane and reaction raw material technology, applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of chemical reagent residue, damage to fiber structure, easy aggregation of inorganic nanoparticles, etc., to achieve increased breaking strength, The effect of improving elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The initiator is: azobisisobutyronitrile; the solvent is: N, N-dimethylformamide; the terminator is: p-hydroxyphenol.

[0053] S1: Preparation of terpolymer: methyl methacrylate, acrylic acid, polyethylene glycol methacrylate, and azobisisobutyronitrile in a mass ratio of 80:15:5:1.5.

[0054] ① Weigh polyethylene glycol methacrylate and put it into N, N-dimethylformamide, fully dissolve;

[0055] ② Introduce nitrogen, and add acrylate, acrylic acid and azobisisobutyronitrile under nitrogen atmosphere;

[0056] ③Put it in a water bath oscillator for reaction, the working temperature of the water bath oscillator is 70°C, the working time is 16h, and the reaction is terminated with p-hydroxyphenol;

[0057] ④ Evaporation of solvent, vacuum drying to constant quality;

[0058] ⑤ Wash the crude product 3 times alternately with deionized water and absolute ethanol at room temperature;

[0059] ⑥ Vacuum drying to constant quality to obtain purified acrylate, acrylic acid, ...

Embodiment 2

[0064] The initiator is: azobisisobutyronitrile; the solvent is: N, N-dimethylformamide; the terminator is: p-hydroxyphenol.

[0065] S1: Preparation of terpolymer: methyl methacrylate, acrylic acid, polyethylene glycol methacrylate, and azobisisobutyronitrile in a mass ratio of 80:15:5:1.5.

[0066] ① Weigh polyethylene glycol methacrylate and put it into N, N-dimethylformamide, fully dissolve;

[0067] ② Introduce nitrogen, and add acrylate, acrylic acid and azobisisobutyronitrile under nitrogen atmosphere;

[0068] ③Put it in a water bath oscillator for reaction, the working temperature of the water bath oscillator is 70°C, the working time is 16h, and the reaction is terminated with p-hydroxyphenol;

[0069] ④ Evaporation of solvent, vacuum drying to constant quality;

[0070] ⑤ Wash the crude product 3 times alternately with deionized water and absolute ethanol at room temperature;

[0071] ⑥ Vacuum drying to constant quality to obtain purified acrylate, acrylic acid, ...

Embodiment 3

[0076] The initiator is: azobisisobutyronitrile; the solvent is: N, N-dimethylformamide; the terminator is: p-hydroxyphenol.

[0077] S1: Preparation of terpolymer: methyl methacrylate, acrylic acid, polyethylene glycol methacrylate, and azobisisobutyronitrile in a mass ratio of 80:15:5:1.5.

[0078] ① Weigh polyethylene glycol methacrylate and put it into N, N-dimethylformamide, fully dissolve;

[0079] ② Introduce nitrogen, and add acrylate, acrylic acid and azobisisobutyronitrile under nitrogen atmosphere;

[0080] ③Put it in a water bath oscillator for reaction, the working temperature of the water bath oscillator is 70°C, the working time is 16h, and the reaction is terminated with p-hydroxyphenol;

[0081] ④ Evaporation of solvent, vacuum drying to constant quality;

[0082] ⑤ Wash the crude product 3 times alternately with deionized water and absolute ethanol at room temperature;

[0083] ⑥ Vacuum drying to constant quality to obtain purified acrylate, acrylic acid, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com