Electrochromic device capable of independently controlling electrochromic layers

A technology of electrochromic devices and electrochromic layers, applied in instruments, nonlinear optics, optics, etc., can solve the problems of fading and discoloration of electrochromic layers, and the inability of a single electrochromic layer to be colored independently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

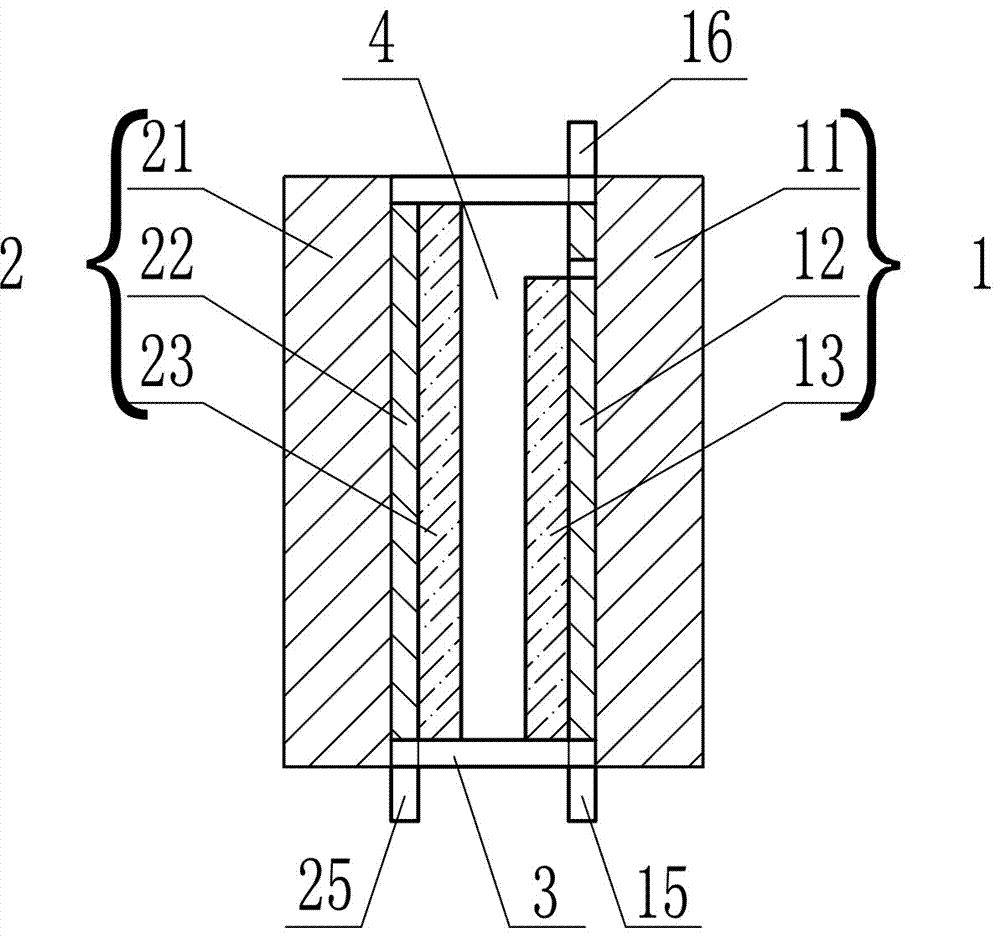

[0040] The electrochromic device that can independently control the electrochromic layer described in this embodiment, by such as figure 1 As shown, it consists of two electrode sheets covered with electrochromic layers, electrolyte layer and edge banding. Among the two electrode sheets covered with an electrochromic layer, one electrode sheet is a single-sided electrode sheet with one layer of electrodes covered with an electrochromic layer, and the other electrode sheet is a one-layer electrode sheet covered with an electrochromic layer. Electrode sheet with single area and single side. The electrochromic device with independently controllable electrochromic layers may have a planar or non-planar shape.

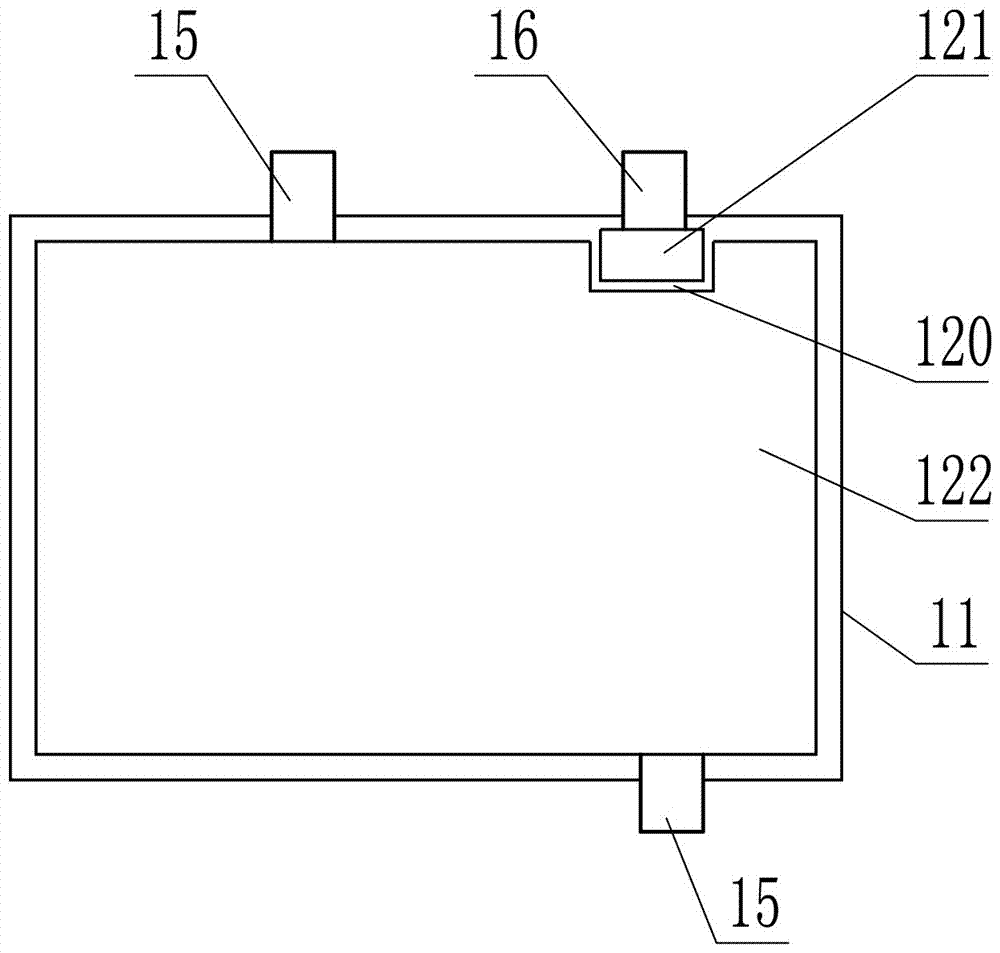

[0041] The one-layer electrode two-region single-sided electrode sheet covered with an electrochromic layer refers to a special electrode sheet for electrochromic devices covered with an electrochromic layer on the electrode layer on the one-layer electrode two-region sing...

Embodiment 2

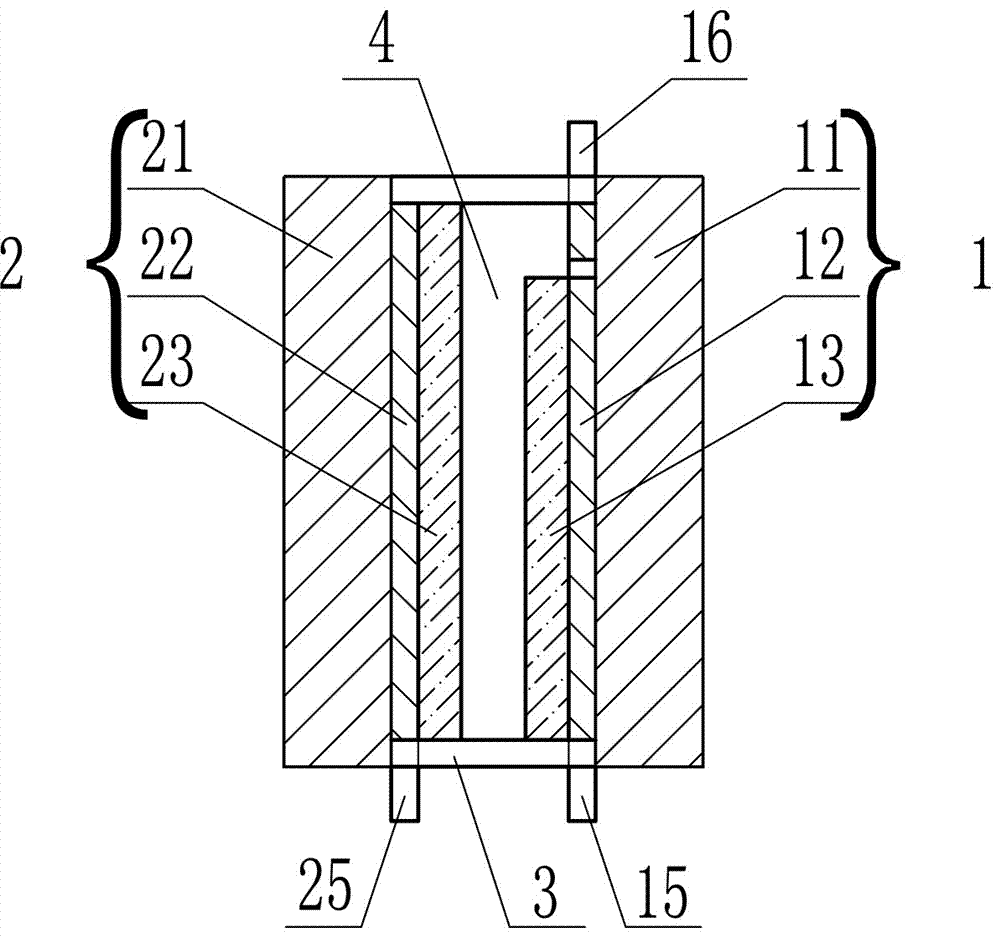

[0056] The electrochromic device described in this embodiment that can independently control the electrochromic layer refers to the electrochromic device that is composed of two electrode sheets covered with an electrochromic layer, an electrolyte layer and a side seal, which can make both sides of the electrochromic layer An electrochromic device in which the color-changing layers can all fade or at least one electrochromic layer in the heteropolar electrochromic layers on both sides can change color independently. The two electrode sheets covered with an electrochromic layer are two electrode sheets with one layer of electrodes and two regions and one surface covered with an electrochromic layer. The electrochromic device with independently controllable electrochromic layers may have a planar or non-planar shape.

[0057] The single-sided electrode sheet with one layer of electrodes and two regions covered with an electrochromic layer is the same as the one-sided electrode s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com