Colored soft hydrophilic contact lens and making method thereof

A contact lens and soft technology, applied in the field of medical devices, can solve the problems of fading and wearing comfort and weakness of the pigment layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Manufacture of coating materials for colored soft hydrophilic contact lenses.

[0045] Weigh 450 g of ethylene glycol monoethyl ether and 45 g of butyl acetate, and stir for 30 minutes. Add it into a four-necked flask, heat it to 140°C±2°C and keep it heated at a constant temperature. Weigh 380g of 2-hydroxyethyl methacrylate (HEMA for short), 30g of methyl methacrylate (MMA for short), 10g of methacrylic acid (MA for short), 20g of styrene, and dibenzoyl peroxide (75 for short). %BPO) 50g, stirred for 2 hours. Then put it into a pear-shaped separating funnel and insert it into a four-necked flask. It was added dropwise to the flask over about 4 hours and allowed to react. Naturally cool to room temperature after stopping heating.

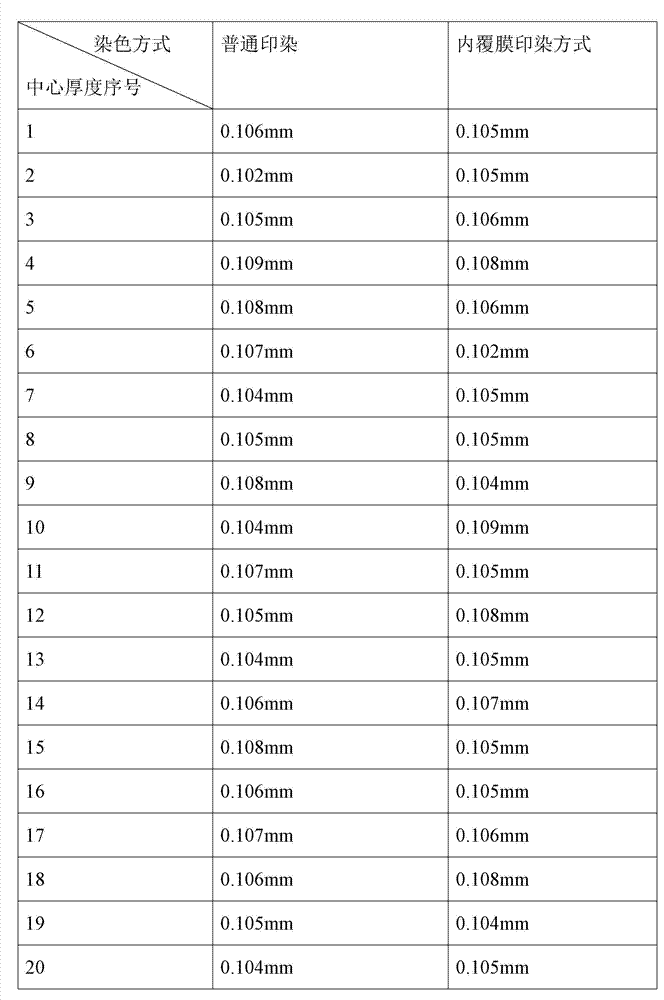

[0046] 2. Manufacture process of colored soft hydrophilic contact lenses by coating dyeing process

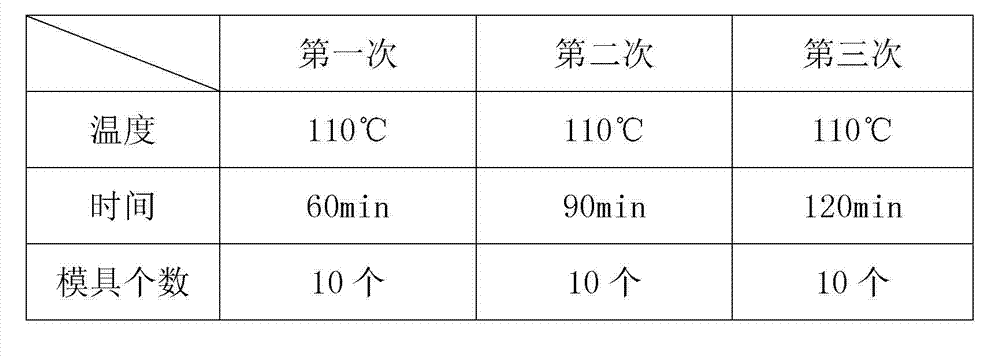

[0047]The process of manufacturing single-color soft hydrophilic contact lens with two-color machine

[0048] Adjust the two-color ...

Embodiment 2

[0052] 1. Manufacture of coating materials for colored soft hydrophilic contact lenses.

[0053] Weigh 480 g of ethylene glycol monoethyl ether and 45 g of butyl acetate, and stir for 30 minutes. Add it into a four-necked flask, heat it to 140°C±2°C and keep it heated at a constant temperature. Weigh 350g of 2-hydroxyethyl methacrylate (HEMA for short), 30g of methyl methacrylate (MMA for short), 10g of methacrylic acid (MA for short), 20g of styrene, and dibenzoyl peroxide (75 for short). %BPO) 40g, stirred for 2 hours. Then put it into a pear-shaped separating funnel and insert it into a four-necked flask. It was added dropwise to the flask over about 4 hours and allowed to react. Naturally cool to room temperature after stopping heating.

[0054] 2. Manufacture process of colored soft hydrophilic contact lenses by coating dyeing process

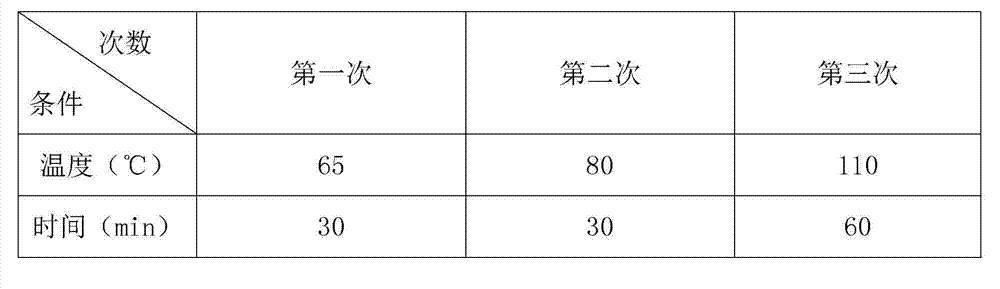

[0055] The process of manufacturing single-color soft hydrophilic contact lens with two-color machine

[0056] Adjust the two-color...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com