Television shell surface UV (ultraviolet) paint spraying technique

A technology for TV casings and paints, applied in the field of TV sets, can solve problems such as affecting the health of construction workers, low spraying efficiency, polluting the environment, etc., and achieve the effects of solving the problems of fading and color difference, improving production efficiency and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A kind of UV paint spraying process for TV front shell surface described in the present invention is described below:

[0018] 1. First understand the basic composition of UV paint components can be summarized as:

[0019] 1>, active diluent

[0020] 2>, oligomers

[0021] 3>, photoinitiator

[0022] 4>, additives

[0023] 2. UV workshop and its equipment requirements:

[0024] The production site is required to be a dust-free workshop, and its UV varnish line supporting equipment: dust removal equipment, spray booth, UV conveyor line, UV curing furnace, purification isolation room, UV lamp, purification air supply system, and electrical control system.

[0025] 3. UV paint spraying process:

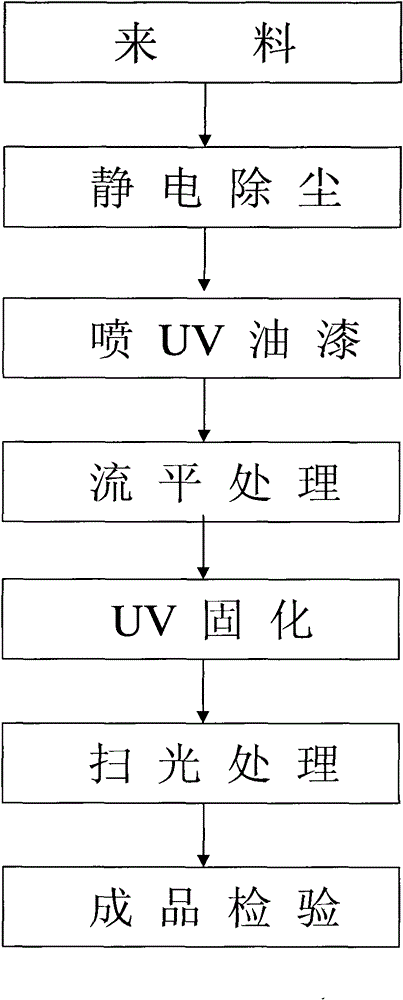

[0026] Loading→electrostatic dust removal→UV oil spraying→UV paint leveling→UV curing→UV sweeping treatment→off-line finished product inspection, the specific operation process is as follows:

[0027] The operator needs to check whether the incoming material is defective in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com