Water-resistant white latex

A technology of white latex and water agent, applied in monocarboxylate copolymer adhesives, adhesive types, adhesive additives, etc., can solve the problems of reduced bonding strength, easy moisture absorption, poor water resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

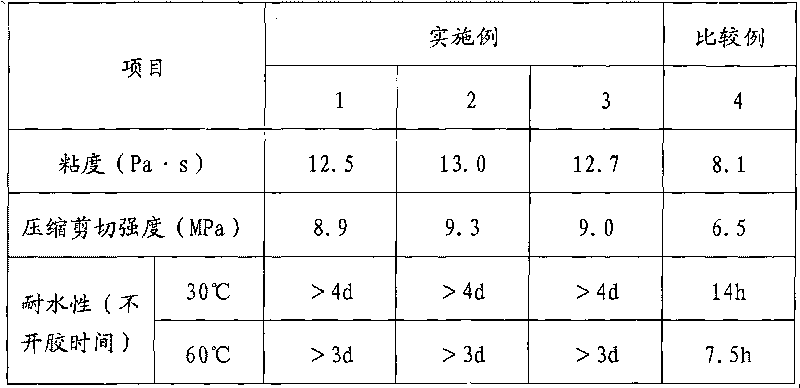

Examples

Embodiment 1

[0031] Proportioning by weight, polyvinyl formal aqueous agent (proportioning by weight: deionized water: polyvinyl alcohol: 10% hydrochloric acid solution: formaldehyde: 10% sodium hydroxide solution: urea=75: 8: 0.05: 1.5: 0.05: 0.5, mixing and reacting evenly) 10 parts were added to the reaction kettle equipped with a reflux condenser and a stirrer, and at a stirring speed of 100 rpm, 0.8 parts of sodium dodecylbenzenesulfonate, 0.4 parts of nonylphenol polyoxyethylene ether, 14 parts of deionized water, and stir for 10 minutes; add 8.4 parts of vinyl acetate, 0.15 parts of 5% ammonium persulfate aqueous solution and 0.3 parts of Defoamer 334, heat up to 65 ° C, and wait until the reflux is basically After disappearing, heat up to 80°C, add 47.6 parts of vinyl acetate and 0.15 parts of ammonium persulfate aqueous solution with a concentration of 5% in the remaining weight parts, dropwise add 2 parts of butyl acrylate and 4 parts of diacetone acrylamide, N - 3 parts of methy...

Embodiment 2

[0033] Proportioning by weight, polyvinyl formal aqueous agent (proportioning by weight: deionized water: polyvinyl alcohol: 10% hydrochloric acid solution: formaldehyde: 10% sodium hydroxide solution: urea=85: 9: 0.1:2:0.1:1, mixing and reacting evenly) 8 parts were added to the reaction kettle equipped with reflux condenser and stirrer, and at a stirring speed of 100 rpm, 0.6 parts of sodium dodecylbenzenesulfonate, 0.4 parts of nonylphenol polyoxyethylene ether, 11 parts of deionized water, and stir for 10 minutes; add 9 parts of vinyl acetate, 0.2 parts of 5% concentration of ammonium persulfate aqueous solution and 0.4 parts of Defoamer 334, heat up to 65 ° C, and wait until the reflux is basically After the disappearance, the temperature was raised to 80°C, and 51 parts of vinyl acetate and 0.2 parts of ammonium persulfate aqueous solution with a concentration of 5% were added dropwise, while 1 part of butyl acrylate and 5 parts of diacetone acrylamide, N-hydroxy 2 parts...

Embodiment 3

[0035] Proportioning by weight, polyvinyl formal aqueous agent (proportioning by weight: deionized water: polyvinyl alcohol: 10% hydrochloric acid solution: formaldehyde: 10% sodium hydroxide solution: urea=90:10: 0.15: 2.5: 0.15: 1.5, mixed and reacted uniformly) 13 parts were added to the reaction kettle equipped with a reflux condenser and a stirrer, and at a stirring speed of 100 rpm, 0.9 parts of sodium dodecylbenzenesulfonate, 0.5 parts of nonylphenol polyoxyethylene ether, 12 parts of deionized water, and stir for 10 minutes; add 7.8 parts of vinyl acetate, 0.1 part of 5% potassium persulfate aqueous solution and 0.2 parts of Defoamer 50A, heat up to 65 ° C, and wait until the reflux is basically After disappearing, heat up to 80°C, add 44.2 parts of vinyl acetate and 0.1 part of potassium persulfate aqueous solution with a concentration of 5% in the remaining weight parts dropwise, and simultaneously add 2 parts of butyl acrylate and 4 parts of diacetone acrylamide, N ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com