Novel high-efficient compound decarbonization solvent

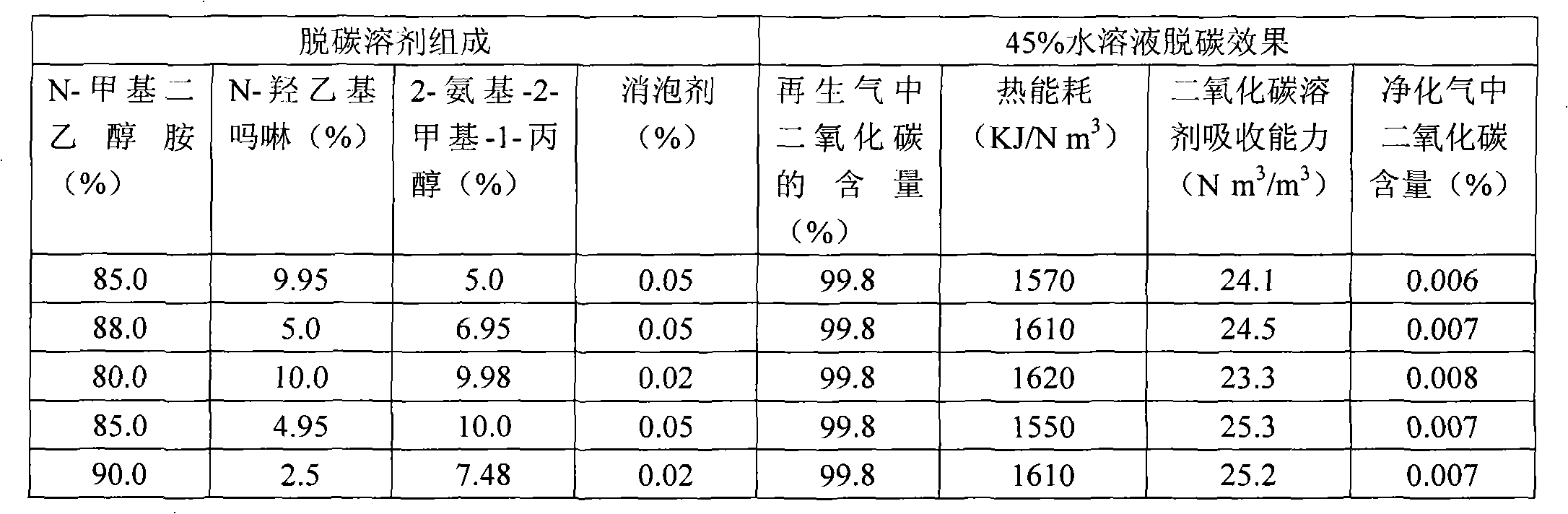

A decarburization and solvent technology, applied in the direction of reagents, carbon compounds, inorganic chemistry, etc., can solve the problems of high alkalinity, affecting the stability of the decarburization system, strong binding force, etc., and achieve good foam suppression and defoaming effects, degassing The carbon process conditions are stable and the solvent use effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

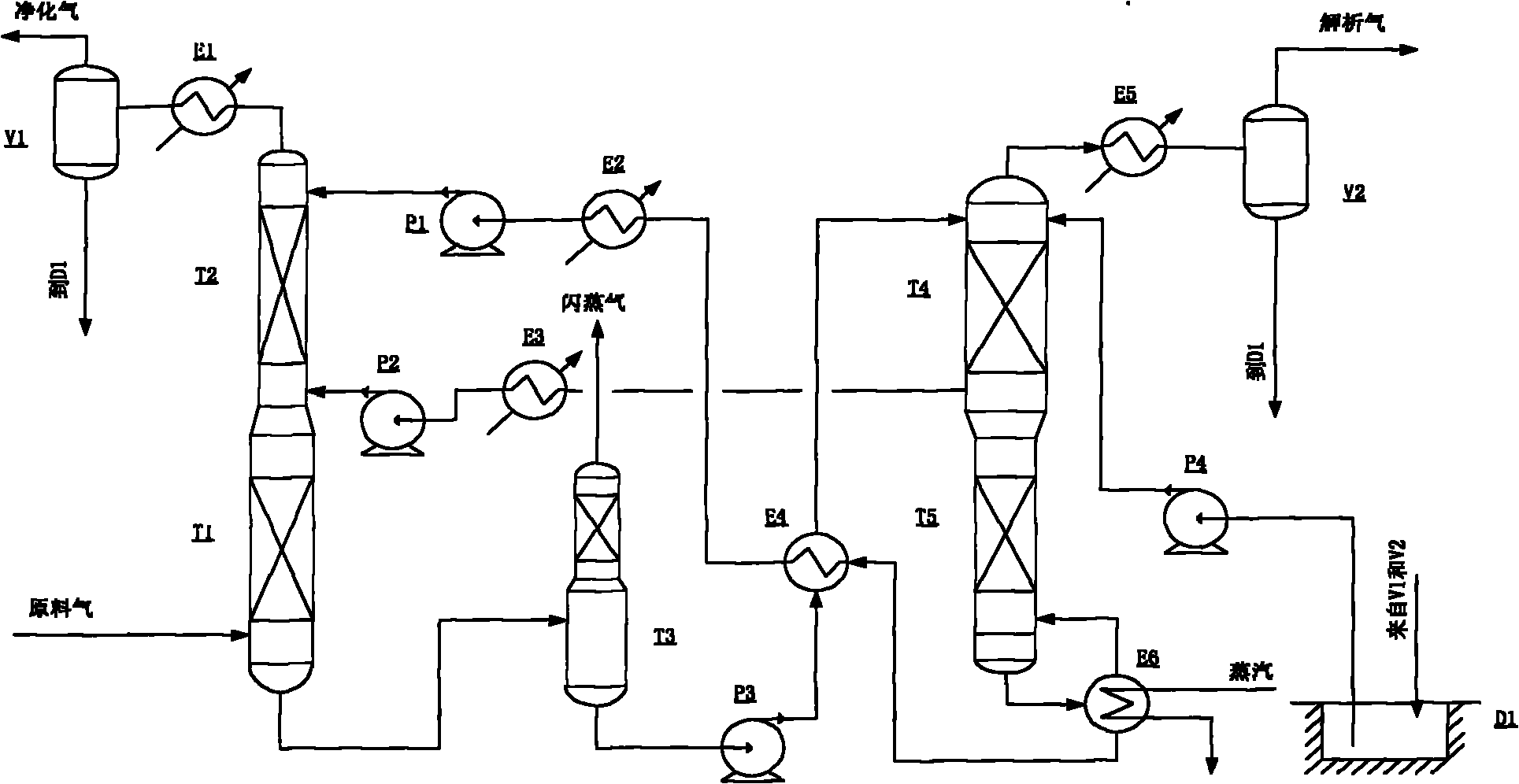

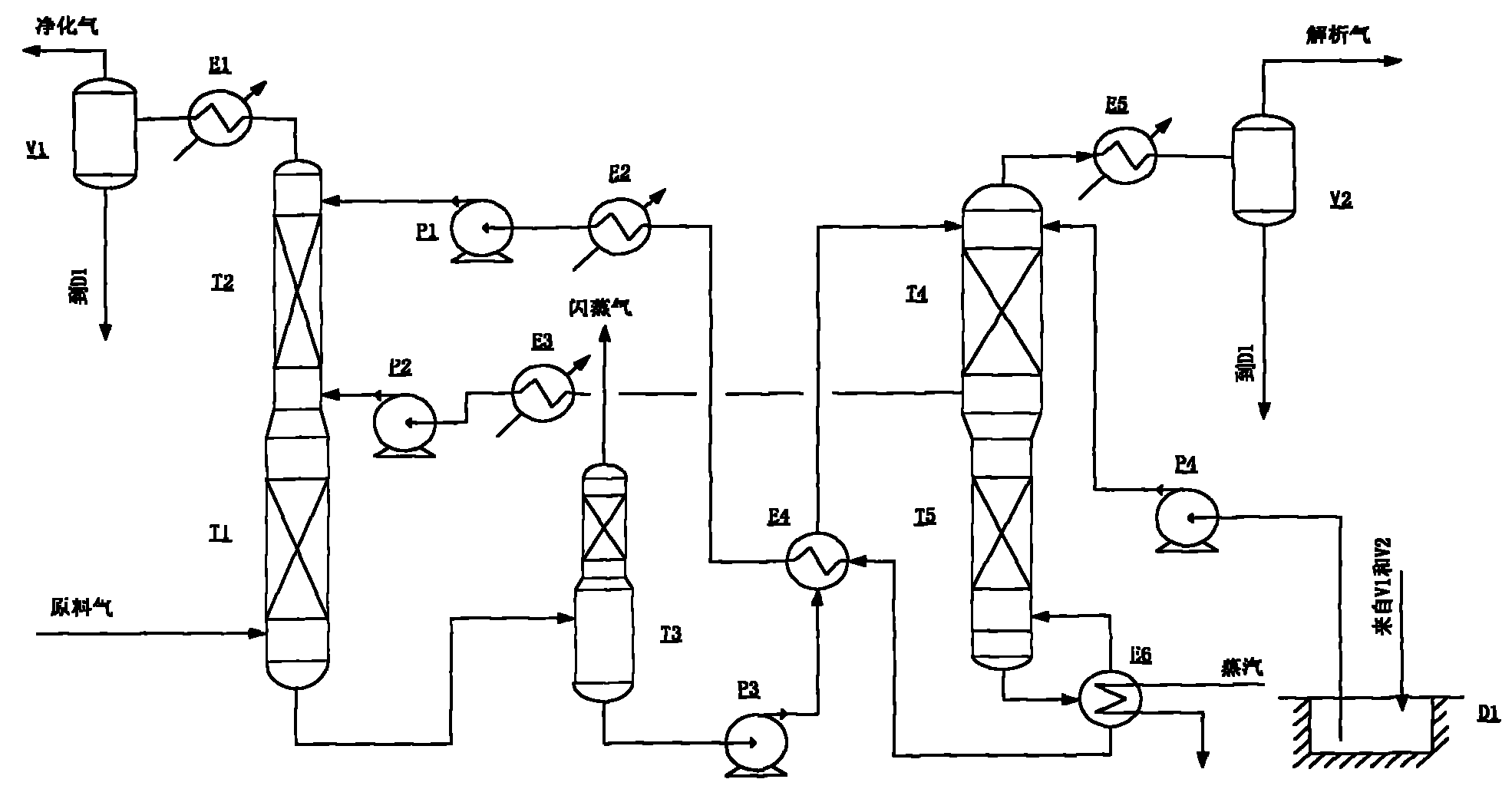

Image

Examples

Embodiment 1

[0042] The composite decarburizer is prepared into a 45% solution with water and used in the carbon dioxide removal section in the ammonia synthesis process flow. The section is: the flow rate of raw gas is 17100Nm 3 / hr, the temperature is 50°C, and the carbon dioxide content is 25.0%.

[0043]

Embodiment 2

[0045] The composite decarburizer is prepared into a 50% solution with water and used in the carbon dioxide removal section in the ammonia synthesis process. In this section: the flow rate of the raw material gas is 16400Nm 3 / hr, the temperature is 73°C, and the carbon dioxide content is 23.5%.

[0046]

Embodiment 3

[0048] The composite decarburizer is formulated with water to make a 50% solution and used in the carbon dioxide removal section in the ammonia synthesis process flow. The section is: the flow rate of raw gas is 16450Nm 3 / hr, the temperature is 40°C, and the carbon dioxide content is 28.0%.

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com