Production process of 2-amino-methyl-1-propanol

A production method, methyl technology, applied in the production field of 2-amino-2-methyl-1-propanol, can solve problems such as complex process conditions, long reaction time, complicated post-treatment, etc., and achieve simple process and low cost Low, high product yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A production method of 2-amino-2-methyl-1-propanol, comprising the following steps:

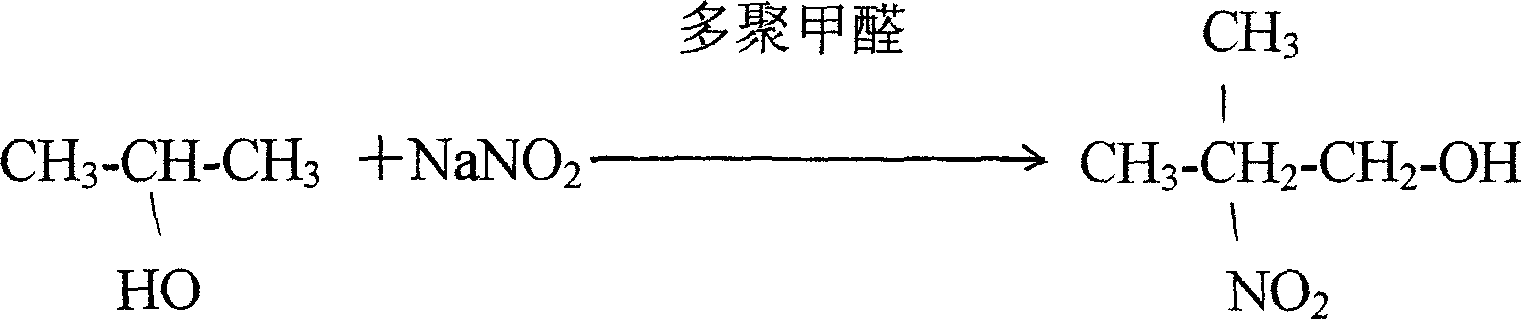

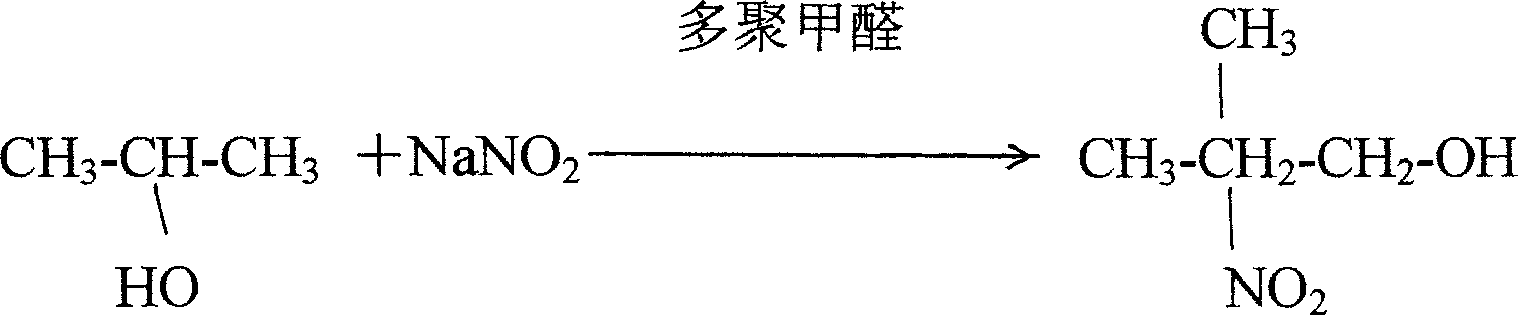

[0013] (1) Sodium nitrite is reacted with isopropanol and paraformaldehyde to generate 2-nitro-2-methyl-1-propanol, and the amount of paraformaldehyde is 1 to 5 times that of isopropanol (for example 1, 3, 5 times), the amount of sodium nitrite is 1 to 3 times the amount of paraformaldehyde (example 1, 2, 3 times). The reaction temperature is 0-25°C (eg 0°C, 15°C, 25°C), and the reaction time is 4-14 hours (eg 4, 10, 14 hours). The reaction formula is:

[0014]

[0015] After extraction with dichloromethane, it was washed with sodium carbonate solution and water until neutral, and the solvent was evaporated to obtain 2-nitro-2-methyl-1-propanol.

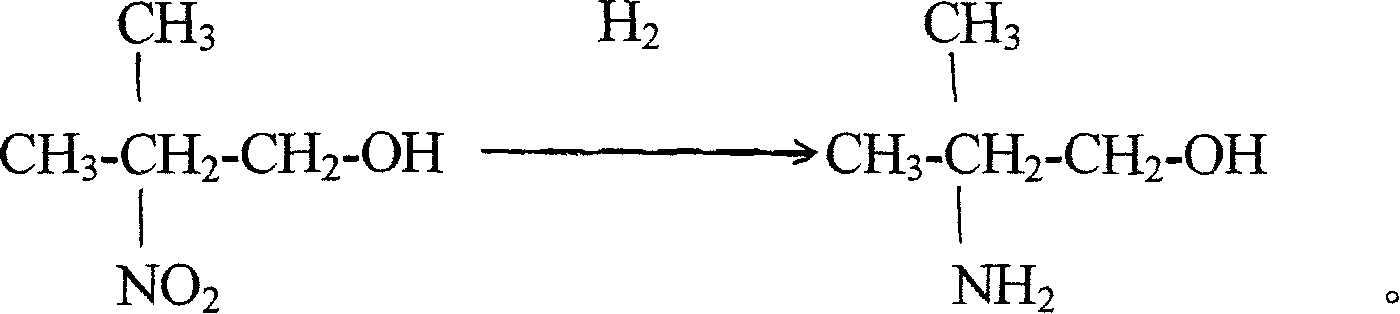

[0016] (2) React 2-nitro-2-methyl-1-propanol with hydrogen to generate 2-amino-2-methyl-1-propanol in the presence of catalyst ruthenium / molecular sieve, and the reaction temperature is 35 to 55 ℃ (example 35 ℃, 45 ℃, 55 ℃), reaction ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com