Environment-friendly emulsion paint and preparation

A kind of latex paint, environment-friendly technology, applied in the direction of latex paint, epoxy resin paint, paint containing biocide, etc., can solve the problems of unsatisfactory application effect, improve human immunity, increase fullness and flexibility, The effect of reducing VOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

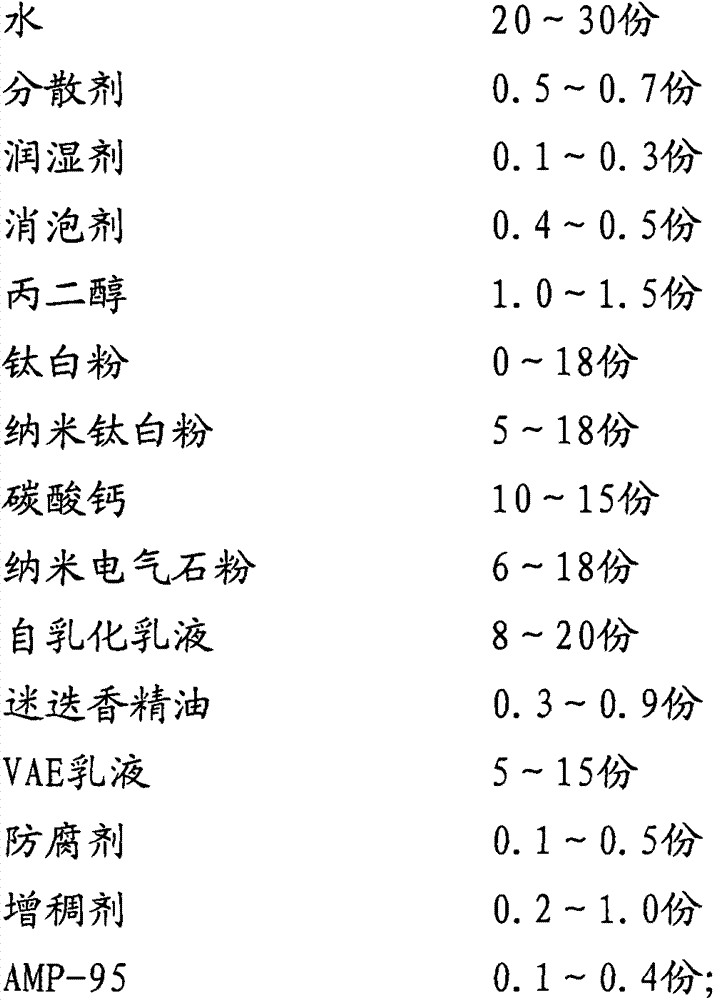

Method used

Image

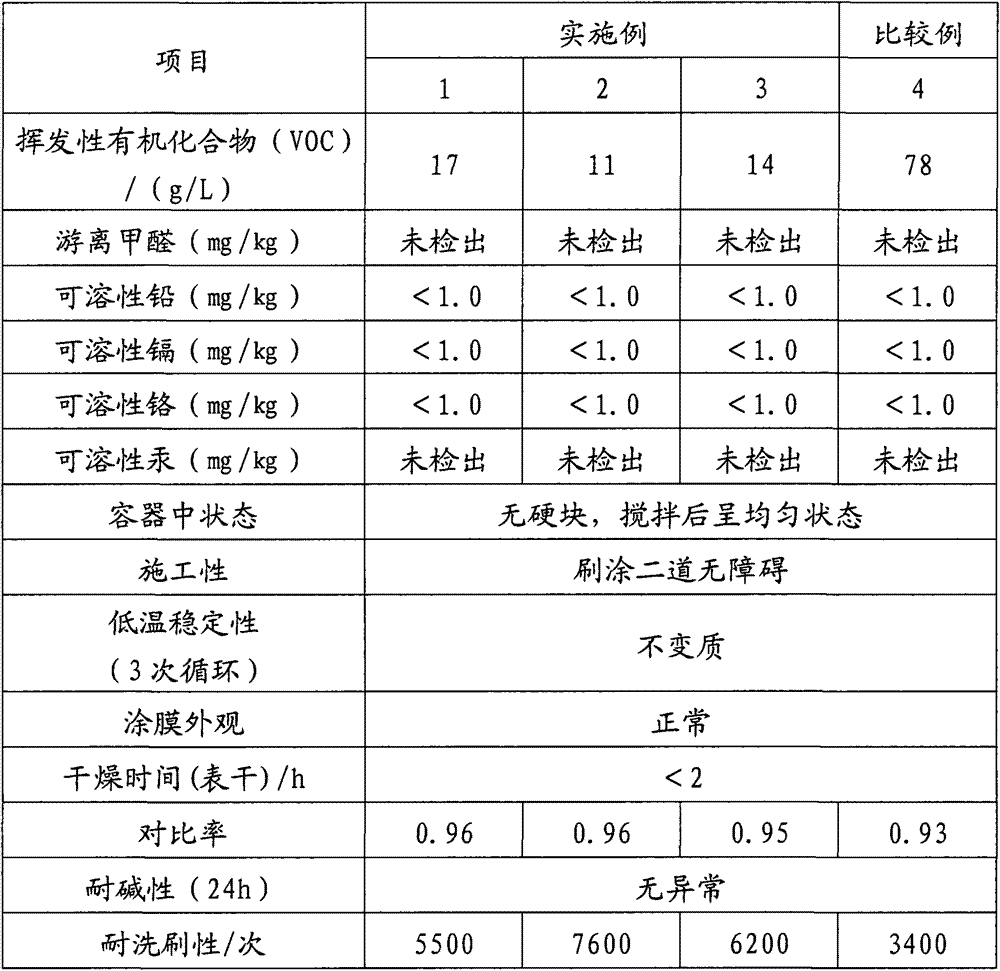

Examples

Embodiment 1

[0032] (1) 8 parts of self-emulsifying emulsion and 0.3 part of rosemary essential oil are put into the dispersion kettle according to the proportion by weight, and the mixture is obtained after stirring;

[0033] (2) According to the proportion by weight, put 24 parts of water into the reaction kettle, put in 20.5 parts of Clariant KANALENE9, 50.3 parts of Dow BD-405, 0.2 parts of Corning Foamstar2230.2 parts, and 1.3 parts of propylene glycol under stirring state, and disperse evenly; Nano-titanium dioxide TTO-5518 parts, calcium carbonate 15 parts, nano-tourmaline powder 6 parts, dispersed evenly; slowly add the mixed solution obtained in step (1), 15 parts of VAE emulsion; finally put in Deqian Defom w-0970.2 parts, Dow Chemical 10.1 parts of ROCIMA555, 1 part of Rockwood OPTIFLO L1001, 0.4 parts of AMP-950.4 parts, 5.9 parts of water, dispersed evenly, and filtered with 120 mesh filter cloth to obtain the finished product.

Embodiment 2

[0035] (1) Put 12 parts of self-emulsifying emulsion and 0.6 part of rosemary essential oil into the dispersion kettle according to the proportion by weight, and stir to obtain the mixed solution;

[0036] (2) According to the proportion by weight, put 15 parts of water into the reaction kettle, and put in 0.6 parts of Corning Dispersant50404, 0.2 parts of Deqian Fx365, 0.25 parts of Nopco SN-DEFOAMER328, and 1 part of propylene glycol under stirring. Disperse evenly; put in 10 parts of titanium dioxide, nano-titanium dioxide TTO-558 parts, 10 parts of calcium carbonate, and 18 parts of nano-tourmaline powder, and disperse evenly; slowly add the mixture obtained in step (1) and 10 parts of VAE emulsion; finally put in Deqian 0.2 parts of Defomw-097, 0.3 parts of Sol Acticde RS, 0.7 parts of Corning DSX38000, 0.2 parts of AMP-950, 5 parts of water, disperse evenly, and filter with 120 mesh filter cloth to obtain the finished product.

Embodiment 3

[0038] (1) Put into the dispersing kettle according to the proportion by weight, 20 parts of self-emulsifying emulsion, 0.9 part of rosemary essential oil, stir well to obtain the mixed solution;

[0039] (2) According to the proportion by weight, put 20 parts of water into the reaction kettle, put in 0.7 parts of Corning Dispersant5040, 0.1 parts of Dow BD-1090.1 parts, 0.3 parts of Corning Foamstar2230.3 parts, and 1.5 parts of propylene glycol under stirring state, and disperse evenly; Put in 18 parts of titanium dioxide, 13 parts of nano-titanium dioxide TTO-555 parts, 13 parts of calcium carbonate, and 12 parts of nano-tourmaline powder, and disperse evenly; slowly add the mixture obtained in step (1) and 5 parts of VAE emulsion; finally put in Deqian Defom w- 0970.2 parts, 0.5 parts of Dow Chemical LXE, 0.2 parts of Rockwood OPTIFLO L1000, 0.1 parts of AMP-950.1 parts, 4.9 parts of water, dispersed evenly, and filtered with 120 mesh filter cloth to obtain the finished pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com