Finish-coat paint for real stone paint and preparation method of finish-coat paint

A technology of top coat and real stone paint, applied in the field of architectural decoration coatings, can solve the problems of poor stain resistance, lack of self-cleaning ability, etc., to reduce blooming, improve weather resistance, and reduce paint film gloss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

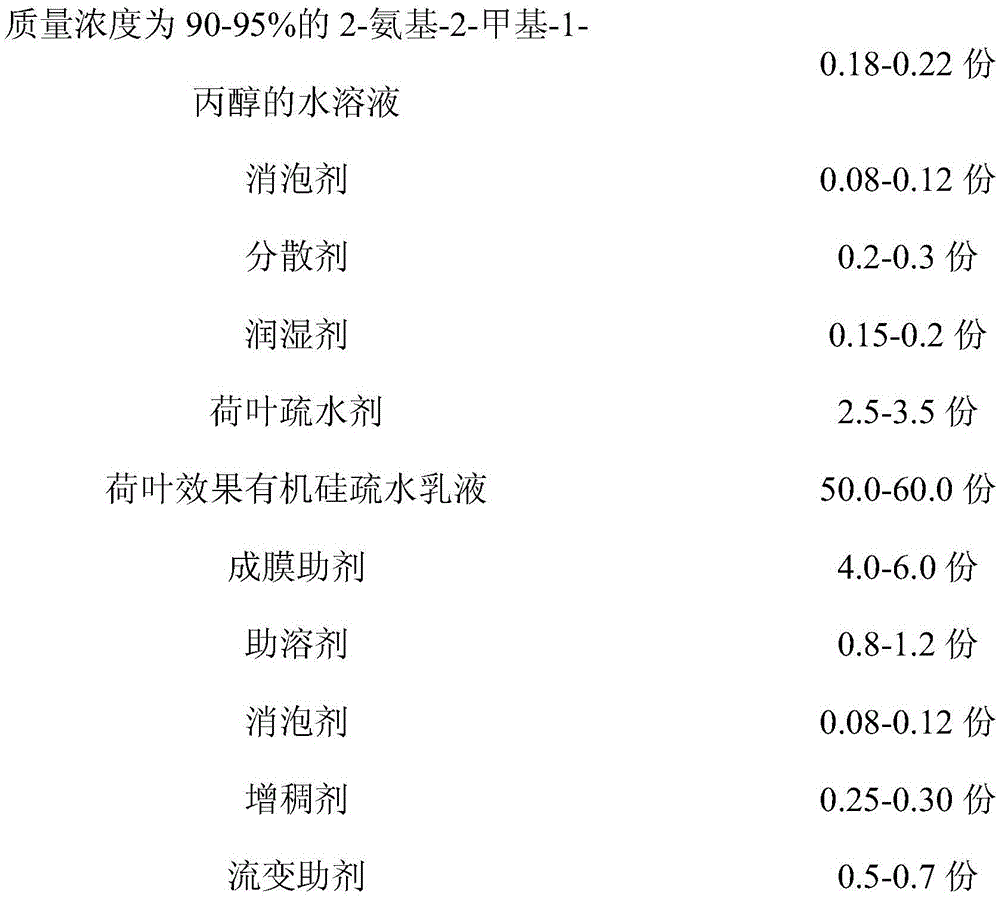

[0037] A kind of finish paint for real stone paint, it is formulated by the following components in weight ratio:

[0038]

[0039]

[0040] The real stone paint is used for finishing paint, and it comprises the following steps carried out in sequence:

[0041] (1) Under stirring at 650r / min rotating speed, add divalent metal salt-stabilized Kathon fungicides and natural bentonite to the water in sequence, stir for 4 minutes, and continue to add 2-amino-2- For the aqueous solution of methyl-1-propanol, increase the rotation speed to 900r / min after adding, and stir for 8min;

[0042] (2) Add defoamer, polyacrylic acid sodium salt dispersant, wetting agent, and highly dispersed nano-scale powders treated with hydroxyl groups to the mixture prepared in step (1) in sequence under stirring at a speed of 700r / min. Titanium dioxide, nano-zinc oxide dispersion in water, non-ionic microemulsion compounded by amorphous silica-type matte powder, ultra-high molecular weight polysil...

Embodiment 2

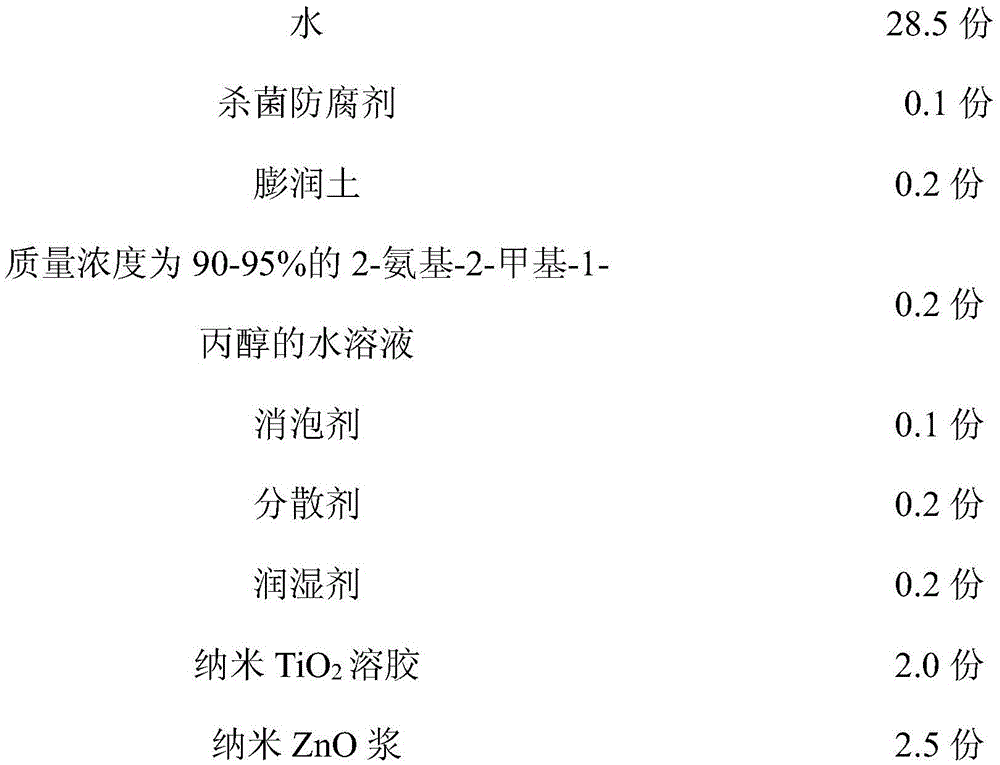

[0045] A kind of finish paint for real stone paint, it is formulated by the following components in weight ratio:

[0046]

[0047]

[0048] The real stone paint is used for finishing paint, and it comprises the following steps carried out in sequence:

[0049] (1) Add bactericidal preservative and artificially modified bentonite to the water under stirring at a speed of 500r / min, stir for 5min, and continue to add 2-amino-2-methyl-1-propane with a mass concentration of 90% while stirring Alcohol aqueous solution, after adding, increase the speed to 800r / min, and stir for 10min;

[0050](2) Add organosilicon defoamer, polyacrylate ammonium salt dispersant, wetting agent, nano-TiO 2 Sol, nano-ZnO slurry, amorphous silica-type dumb powder, lotus leaf hydrophobic agent, increase the speed to 1000r / min after adding, and stir for 5-10min;

[0051] (3) Add organosiloxane-modified acrylate copolymer emulsion, film-forming aid, co-solvent, Defoamer, hydrophobic modified alkal...

Embodiment 3

[0053] A kind of finish paint for real stone paint, it is formulated by the following components in weight ratio:

[0054]

[0055]

[0056] The real stone paint is used for finishing paint, and it comprises the following steps carried out in sequence:

[0057] (1) Under 750r / min rotating speed stirring, add bactericidal antiseptic, bentonite to water sequentially, stir 3min, continue to add the aqueous solution of 2-amino-2-methyl-1-propanol that mass concentration is 92% while stirring After adding, increase the speed to 1000r / min and stir for 5min;

[0058] (2) Add emulsion type defoamer, dispersant, wetting agent, lotus leaf hydrophobic agent successively to the mixture prepared in step (1) under stirring at a rotating speed of 750r / min, increase the rotating speed to 800r / min after adding, Stir for 10 minutes;

[0059] (3) Add organosiloxane-modified acrylate copolymer emulsion, film-forming aid, co-solvent, Add defoamer, thickener and rheological additive, and k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com