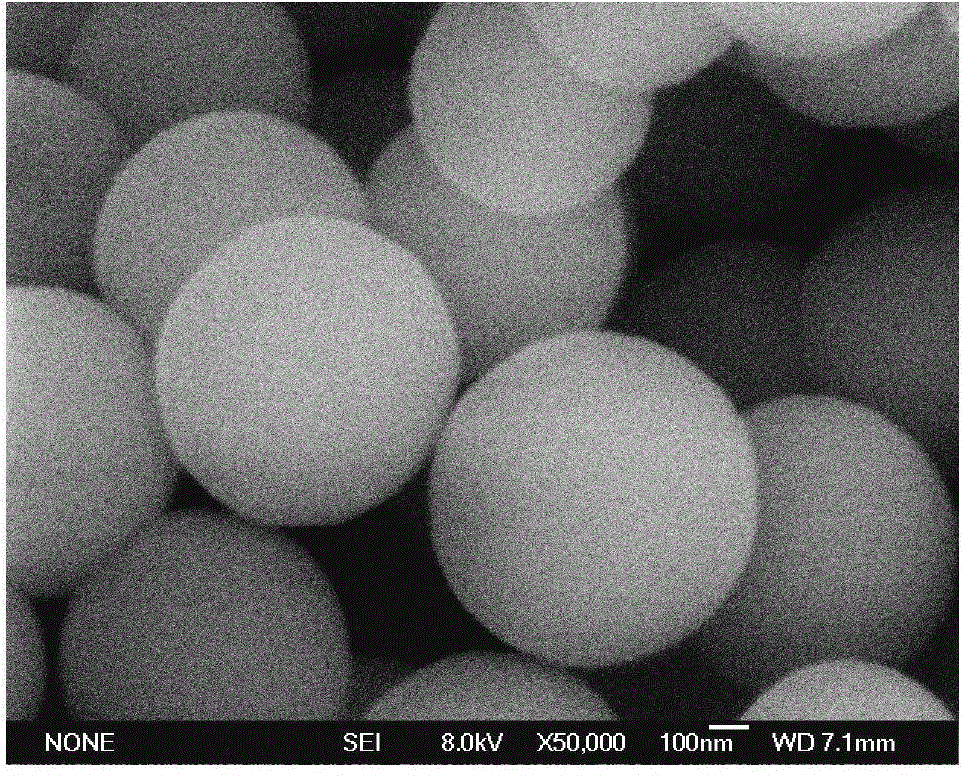

SiO2/MoS2 core-shell-structure microspheres and preparation method thereof

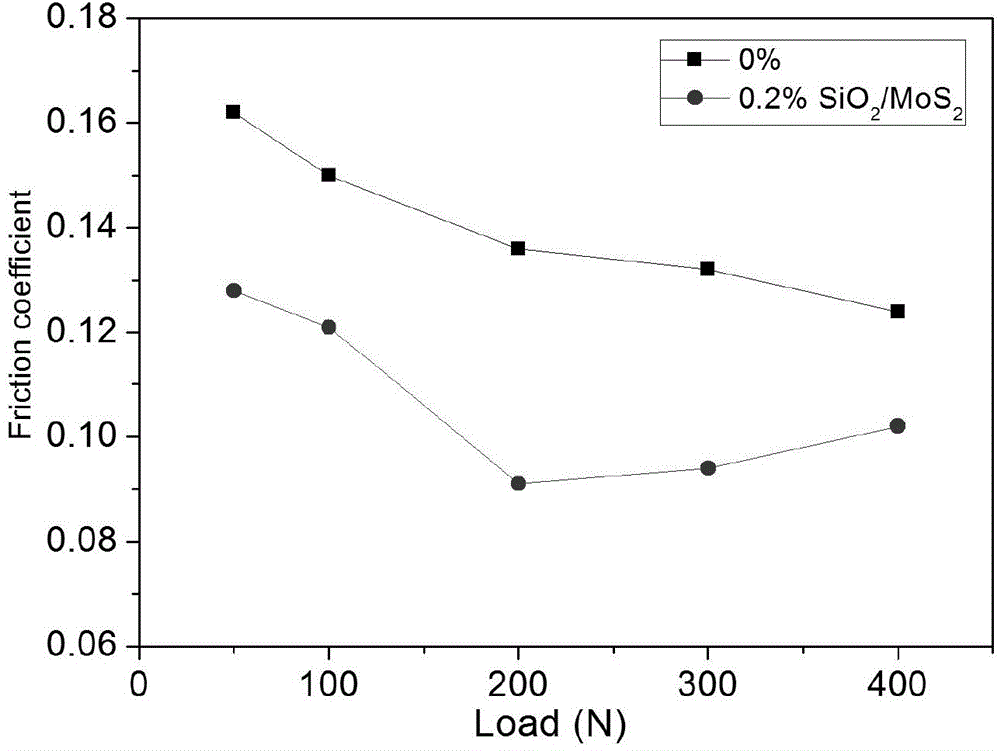

A core-shell structure and microsphere technology, applied in the directions of additives, lubricating compositions, petroleum industry, etc., can solve the problems of easy agglomeration, difficult dispersion, anti-wear and anti-friction properties of nano-silica and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Add 20 mL of absolute ethanol to the beaker, then add 1 mL of TEOS, 1 mL of triethanolamine, and 1 mL of distilled water in sequence, and stir at 20 °C for 6 h to prepare SiO 2 Microspheres. centrifuged, the resulting SiO 2 Re-disperse in 40ml water, add 0.35g ammonium molybdate, 0.4g polyvinylpyrrolidone (K30) and 0.1g copper reagent in turn, after stirring evenly, pour the mixed reactant into the autoclave; in the oven at 200℃ After reacting for 24 hours, take it out, centrifuge, wash with water, wash with alcohol, and dry.

Embodiment 2

[0015] Add 30 mL of absolute ethanol to the beaker, then add 2 mL of TEOS, 1 mL of triethanolamine, and 2 mL of distilled water in sequence, and stir at 10 °C for 6 h to prepare SiO 2 Microspheres. centrifuged, the resulting SiO 2 Redisperse in 40ml of water, add 0.1g ammonium molybdate, 0.2g polyvinylpyrrolidone (K30) and 0.05g copper reagent in turn, after stirring evenly, pour the mixed reactant into the autoclave; in the oven at 220℃ After reacting for 24 hours, take it out, centrifuge, wash with water, wash with alcohol, and dry.

Embodiment 3

[0017] Add 20mL of absolute ethanol to the beaker first, then add 1mL TEOS, 2mL diethanolamine, 1mL distilled water in turn, and stir at 20°C for 12h to prepare SiO 2 Microspheres. centrifuged, the resulting SiO 2 Redisperse in 40ml of water, add 0.2g ammonium molybdate, 0.4g polyvinylpyrrolidone K30 and 0.1g copper reagent in turn, after stirring evenly, pour the mixed reactants into the autoclave; react in an oven at 220°C for 24h , taken out, centrifuged, washed with water, washed with alcohol, and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com