Environment-friendly type terylene low temperature dyeing assistant with alkyl phthalic imide as vector and preparation thereof

An alkyl phthalimide and low-temperature dyeing technology, which is applied in the fields of dyeing, textiles and papermaking, can solve the problems of decreased dispersion stability of dye liquor, long dyeing time, and difficult dyeing, and achieves bright color and Brightness, shorter dyeing time, and higher dyeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-5

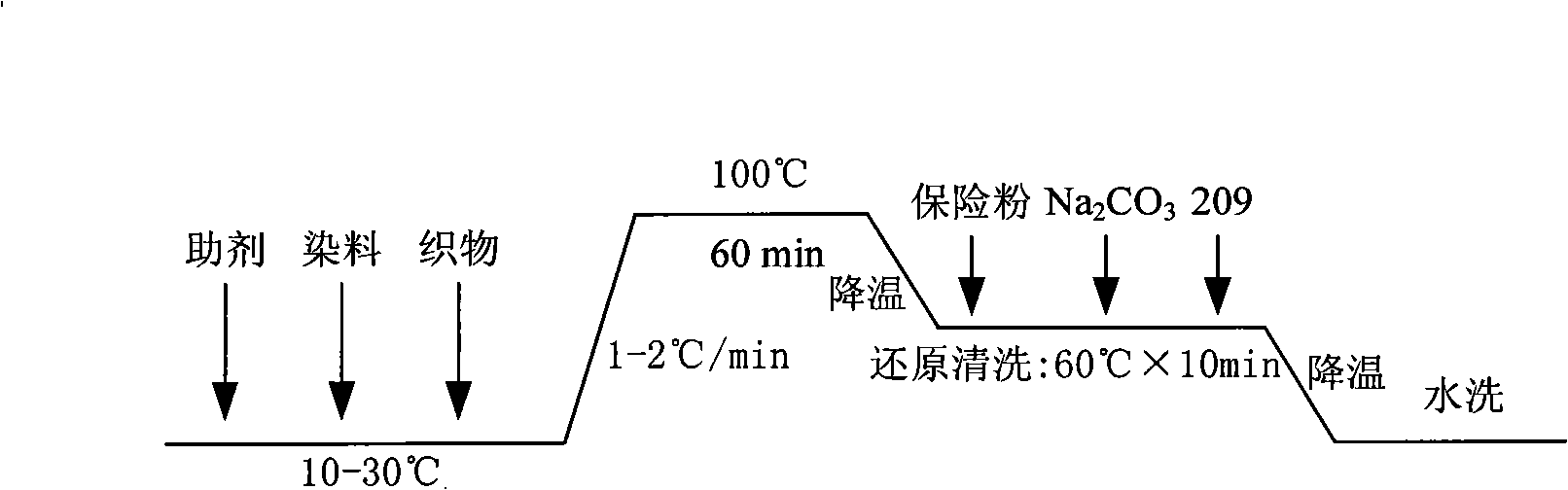

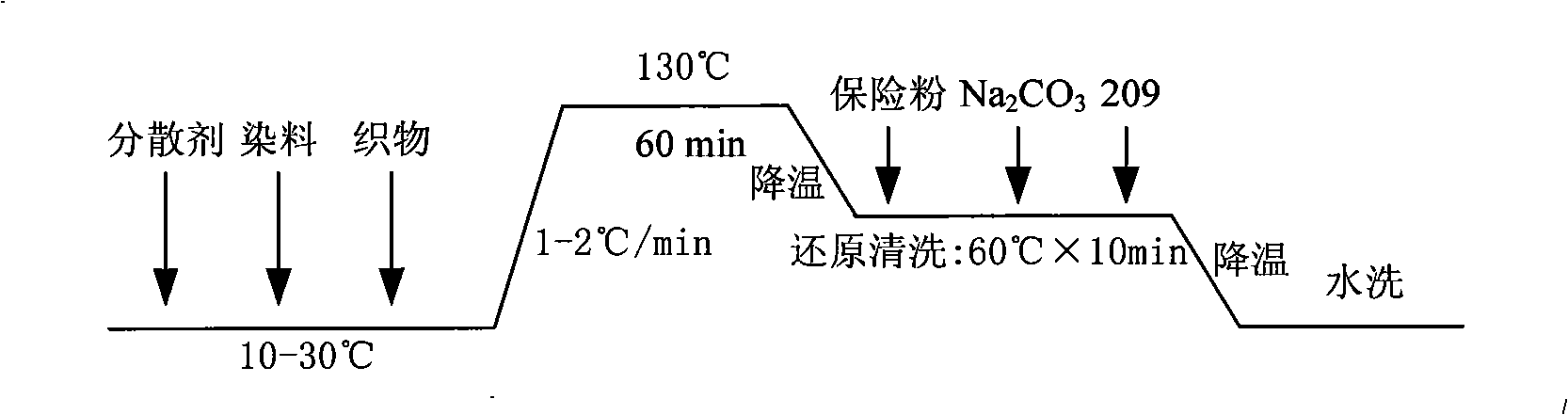

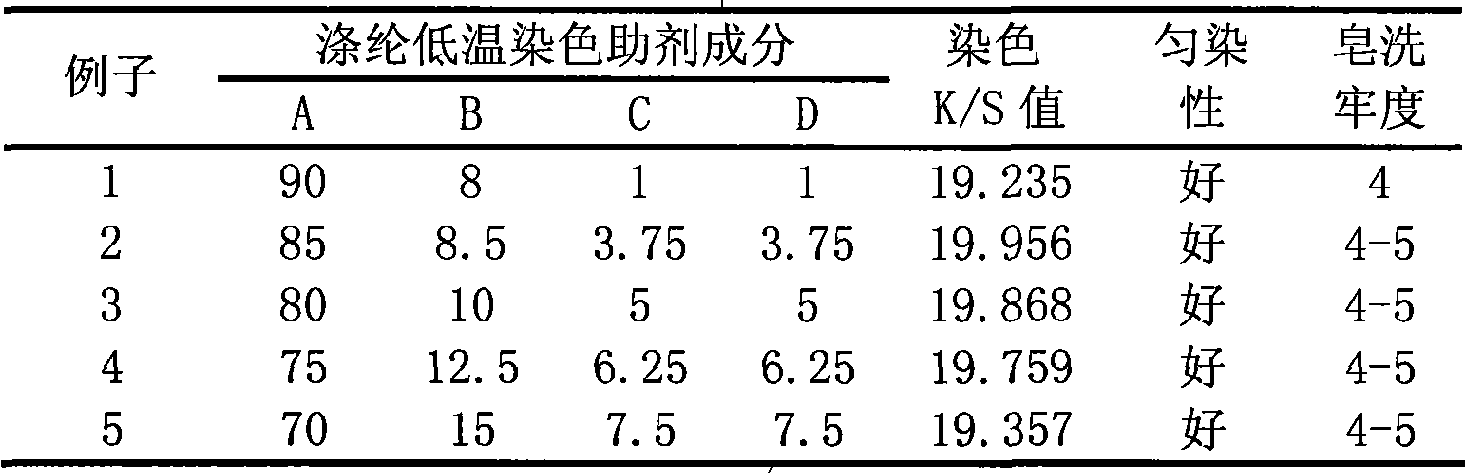

[0032] Select the high-temperature disperse dye Runtu Hongyu H-2GFL, the concentration is 2% (o.w.f), the dosage of dispersant NNO is 1g / L, the dosage of polyester low-temperature dyeing auxiliaries is 2g / L, the dosage of sodium hydrosulfite is 2g / L, Na 2 CO 3 The dosage is 4g / L, the dosage of 209 detergent is 2g / L, the dyeing pH value is 4-5, the bath ratio is 1:30, the dyeing process curve is shown in figure 1 , polyester low-temperature dyeing auxiliaries and corresponding dyeing results are shown in Table 1.

[0033] Table 1

[0034]

[0035] Note: A: Alkyl phthalimide compounds (N-butyl phthalimide: isopropyl phthalimide = 3:1), B: Nong emulsion 8206 , C: castor oil polyoxyethylene ether sulfonate: EL-60 sodium sulfonate, D: alkylphenol polyoxyethylene ether: TX-40; the mixing temperature of example 1-3 is 40 ° C, the mixing of example 4-5 The temperature is 60°C.

example 6-10

[0037] Select the high-temperature disperse dye Disperse Yellow S-4GL, the concentration is 2% (o.w.f), the dosage of dispersant NNO is 1g / L, the dosage of polyester low-temperature dyeing auxiliaries is 2g / L, the dosage of sodium hydrosulfite is 2g / L, Na 2 CO 3 The dosage is 4g / L, the dosage of 209 detergent is 2g / L, the dyeing pH value is 4-5, the bath ratio is 1:30, the dyeing process curve is shown in figure 1 , polyester low-temperature dyeing auxiliaries and corresponding dyeing results are shown in Table 2.

[0038] Table 2

[0039]

[0040] Note: A: Alkyl phthalimide compounds (N-butyl phthalimide: isopropyl phthalimide = 3:1), B: Nong emulsion 8206 , C: castor oil polyoxyethylene ether sulfonate: EL-60 sodium sulfonate, D: alkylphenol polyoxyethylene ether: TX-40; the mixing temperature of Example 6-10 is 50°C.

example 11-15

[0042] Select the high-temperature disperse dye disperse dark blue S-RE, the concentration is 2% (o.w.f), the dosage of dispersant NNO is 1g / L, the dosage of polyester low-temperature dyeing auxiliaries is 2g / L, and the dosage of sodium hydrosulfite is 2g / L. 2 CO 3 The dosage is 4g / L, the dosage of 209 detergent is 2g / L, the dyeing pH value is 4-5, the bath ratio is 1:30, the dyeing process curve is shown in figure 1 , polyester low-temperature dyeing auxiliaries and corresponding dyeing results are shown in Table 3.

[0043] table 3

[0044]

[0045]Note: A: Alkyl phthalimide compounds (N-butyl phthalimide: isopropyl phthalimide = 3:1), B: Nong emulsion 8206 , C: castor oil polyoxyethylene ether sulfonate: EL-60 sodium sulfonate, D: alkylphenol polyoxyethylene ether: TX-40; the mixing temperature of Examples 11-15 was 50°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com