Coking and fouling inhibitor and use method thereof in heavy oil precessing system

An application method and inhibitor technology, applied in the petroleum industry, treatment equipment corrosion/scaling inhibition, hydrocarbon oil treatment, etc., can solve the problems of poor inhibition effect, inability to inhibit coking and fouling, etc., achieve strong coke inhibition effect, reduce Coking fouling, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

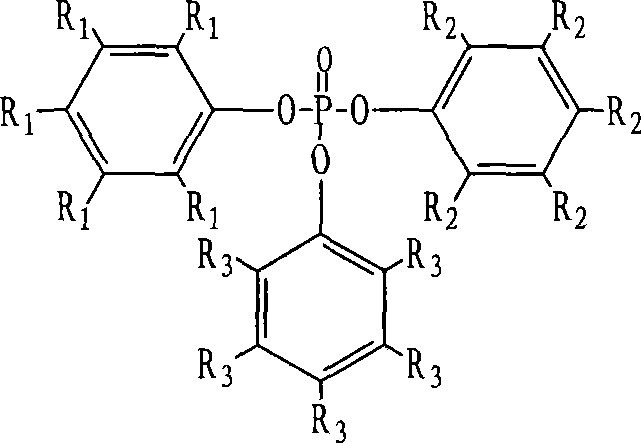

[0035] Add 20 grams of benzotriazole into a container, raise the temperature to 60°C, and add 50 grams of bis-polyisobutylene succinimide, 2-methyl-4,6-di-tert-butyl 50 grams of base phenol and 80 grams of triphenyl phosphate were stirred at a constant temperature to make them evenly mixed, and then cooled to room temperature. The obtained product was used as a coking and fouling inhibitor, and the code number was ANTI-1.

Embodiment 2

[0037] Add 15 grams of the mixture of tolyl benzotriazole and benzotriazole into a container, raise the temperature to 70°C, and add 15 grams of monopolyisobutylene succinimide, 35 grams of 2 , a mixture of 6-di-tert-butylphenol, 135 grams of triphenyl phosphate and trityl methyl phosphate, continue to stir at a constant temperature to make it evenly mixed, then cool to room temperature, the product obtained is used as a coking and scaling inhibitor, and the number is ANTI-2.

Embodiment 3

[0039] Add a mixture of 90 grams of 2-mercaptobenzotriazole and imidazoline into a container, raise the temperature to 75°C, and add 20 grams of 2,6-di-tert-butylphenol and 2-methyl- A mixture of 4,6-di-tert-butylphenol and 90 grams of triisopropylphenyl phosphate, continue to stir at a constant temperature to make it evenly mixed, and then cool to room temperature. The obtained product is used as a coking and fouling inhibitor, and the number is ANTI- 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com