Waterborne acrylic acid modified epoxy emulsion and high-performance waterborne epoxy anticorrosive coating

A water-based acrylic and epoxy emulsion technology, used in anti-corrosion coatings, coatings, etc., can solve the problem of high VOC content, and achieve the effects of low VOC content, short coating interval, and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

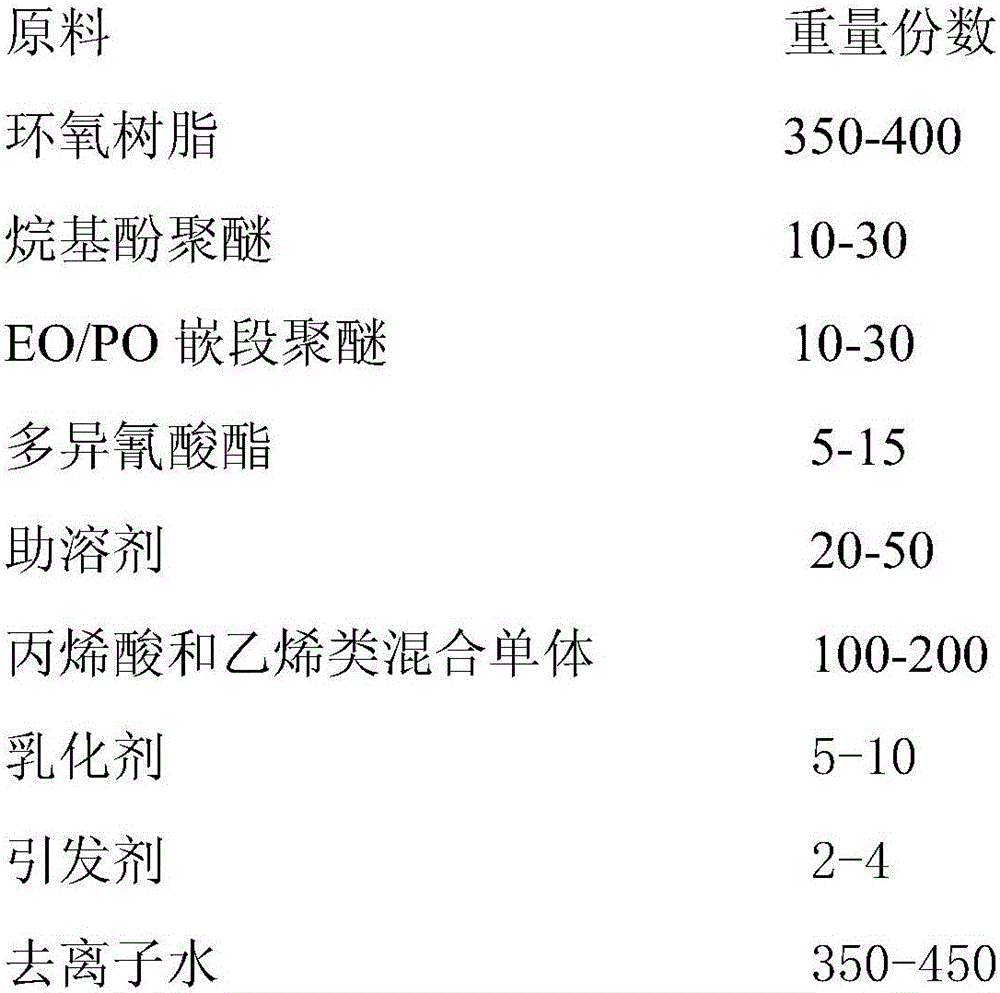

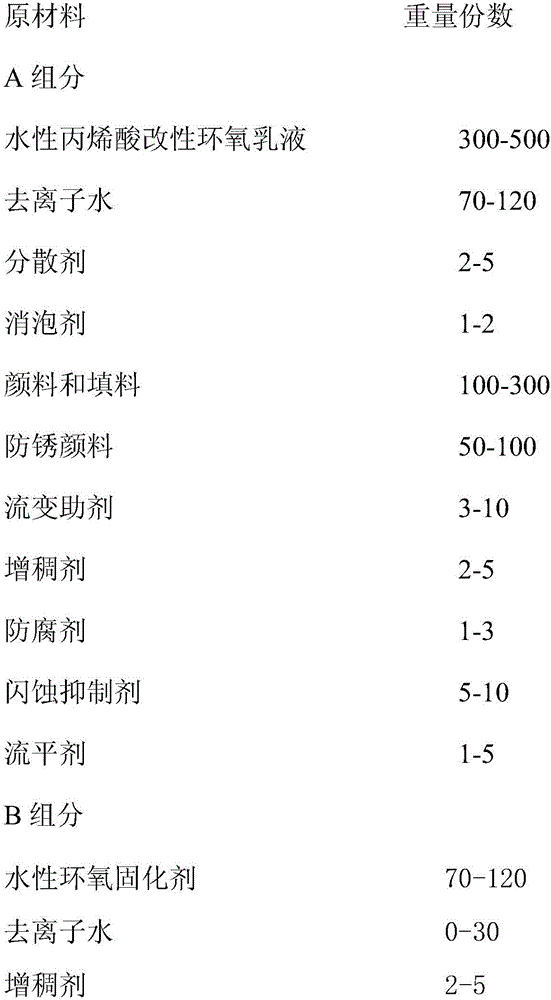

Method used

Image

Examples

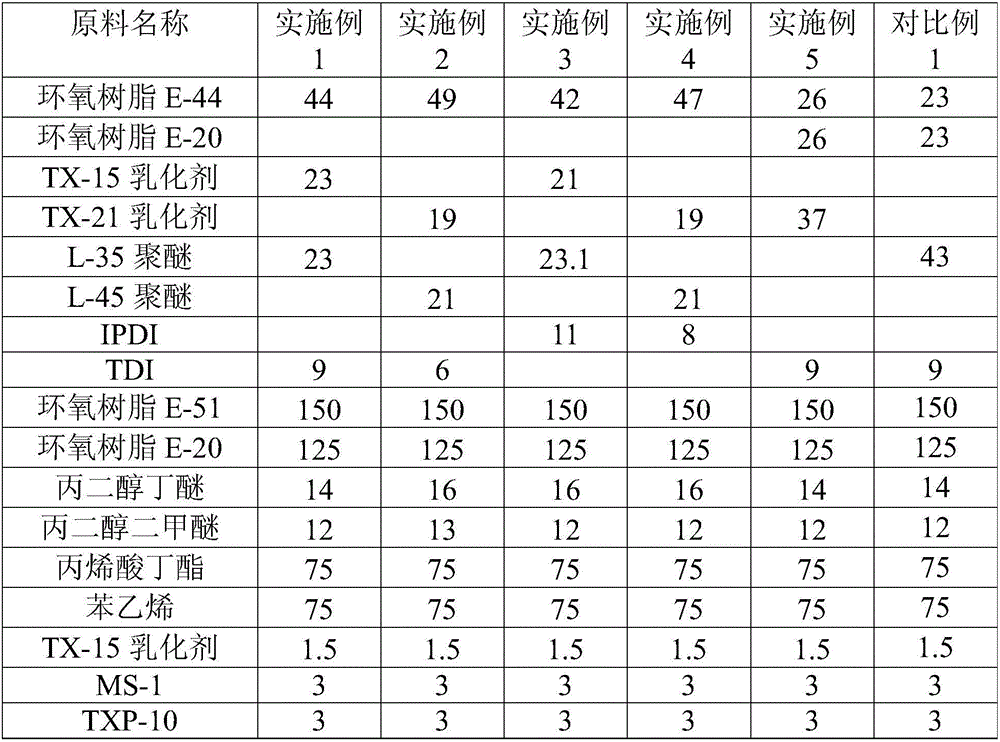

Embodiment 1

[0043] The amounts of the substances in Example 1 are calculated in parts by weight.

[0044] ①Add 9 parts of polyisocyanate (TDI) into the four-neck flask, heat up to 66-70°C, add 23 parts of alkylphenol polyether emulsifier (TX-15), EO / PO block polyether (Haian Chemical Co., Ltd. L-35) 23 parts, continue to stir and keep warm for 2 hours, add 44 parts of E-44 epoxy resin, raise the temperature to 85-90°C, continue to keep warm and stir for 2 hours, and obtain the epoxy resin polyether adduct.

[0045] ② Add 150 parts of E-51 epoxy resin, 125 parts of E-20 epoxy resin, 14 parts of propylene glycol butyl ether, 12 parts of dipropylene glycol methyl ether in the flask, and the epoxy resin polyether adduct obtained in the first step is 99 parts Heat up to 88-92°C and keep stirring until the epoxy resin is completely melted and the mixture is uniform and transparent. Gradually add 300 parts of deionized water and stir until phase inversion. Cool down to 70-80°C to form an O / W emu...

Embodiment 2

[0048] The preparation process of embodiment 2 is the same as that of embodiment 1. The alkylphenol polyether used in the preparation of the epoxy polyether adduct is TX-21, and the block polyether is L-45. The polyisocyanate is TDI. The obtained emulsion is uniform and fine, with good stability; viscosity: 2100mPa.s; solid content: 52.5%; uniform and smooth coating film.

Embodiment 3

[0049] The preparation process of embodiment 3 is the same as that of embodiment 1. The alkylphenol polyether used in the preparation of the epoxy polyether adduct is TX-15, and the block polyether is L-35. The polyisocyanate is IPDI. The obtained emulsion is uniform and delicate, with good stability; viscosity: 1700mPa.s; solid content: 52.6%; uniform and smooth coating film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com