Preparation method of irradiation cross-linking polyolefin insulating material for locomotives

A technology for cross-linking polyolefins and insulating materials, which can be used in organic insulators, insulators, plastic/resin/wax insulators, etc. Effects of strength, high draw ratio and processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

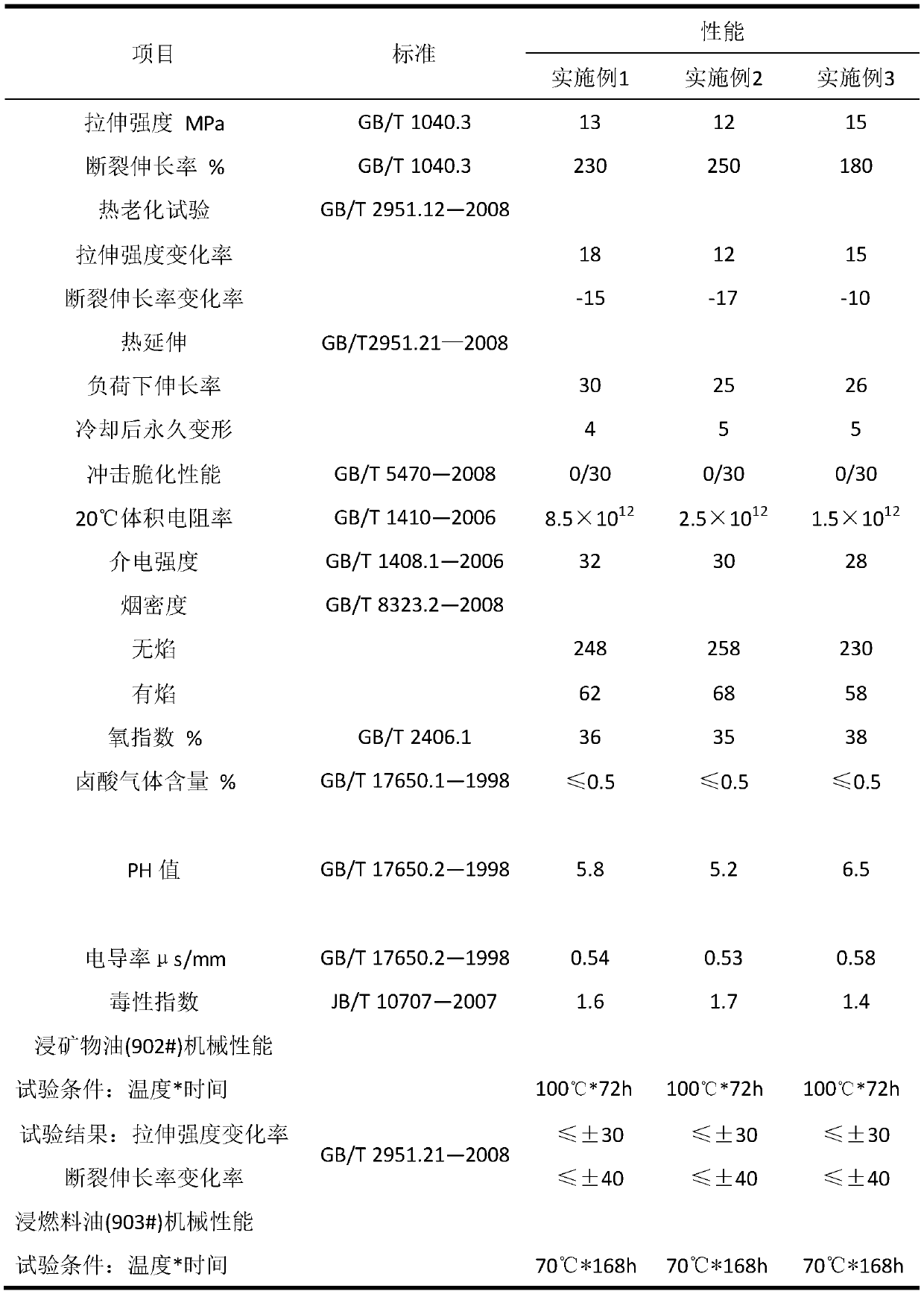

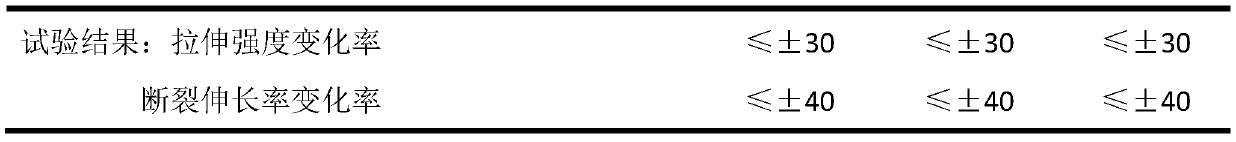

Examples

Embodiment 1

[0023] An irradiation cross-linked polyolefin insulating material for locomotives, comprising the following components in parts by weight: 50 parts of ethylene-vinyl acetate copolymer, 20 parts of metallocene linear low-density polyethylene, 25 parts of ethylene-octene copolymer, 10 parts of ethylene-octene copolymer grafted with anhydride, 100 parts of modified aluminum hydroxide, 60 parts of modified magnesium hydroxide, 50 parts of triazine flame retardant, 2 parts of coupling agent, 3 parts of lubricant, high temperature resistance 1 part of antioxidant, 1.5 parts of light stabilizer, 5 parts of carbon-forming smoke suppressant, 8 parts of modified bentonite, 10 parts of activated kaolin powder, and 3 parts of crosslinking agent.

[0024] Preparation:

[0025] The ethylene-vinyl acetate copolymer, metallocene linear low density polyethylene, ethylene-octene copolymer, maleic anhydride grafted ethylene-octene copolymer, modified aluminum hydroxide, modified hydroxide Magne...

Embodiment 2

[0027] An irradiation cross-linked polyolefin insulating material for locomotives, comprising the following components in parts by weight: 40 parts of ethylene-vinyl acetate copolymer, 30 parts of metallocene linear low-density polyethylene, 15 parts of ethylene-octene copolymer, 15 parts of toric anhydride grafted ethylene-octene copolymer, 150 parts of modified aluminum hydroxide, 50 parts of modified magnesium hydroxide, 80 parts of triazine flame retardant, 1 part of coupling agent, 6 parts of lubricant, high temperature resistance 2 parts of antioxidant, 1 part of light stabilizer, 2 parts of carbon-forming smoke suppressant, 10 parts of modified bentonite, 15 parts of activated kaolin powder, 2 parts of crosslinking agent.

[0028] The preparation method is the same as in Example 1.

Embodiment 3

[0030] An irradiation cross-linked polyolefin insulating material for locomotives, comprising the following components in parts by weight: 40 parts of ethylene-vinyl acetate copolymer, 40 parts of metallocene linear low-density polyethylene, 20 parts of ethylene-octene copolymer, 20 parts of toric anhydride grafted ethylene-octene copolymer, 80 parts of modified aluminum hydroxide, 80 parts of modified magnesium hydroxide, 100 parts of triazine flame retardant, 1 part of coupling agent, 8 parts of lubricant, high temperature resistance 0.5 parts of antioxidant, 3 parts of light stabilizer, 5 parts of carbon-forming smoke suppressant, 15 parts of modified bentonite, 10 parts of activated kaolin powder, and 5 parts of crosslinking agent.

[0031] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com