Preparation method for rubber for piston sealing ring with good anti-aging effect

A sealing ring and anti-aging technology, which is applied in the field of rubber preparation for piston sealing rings, can solve the problems such as the inability to meet the increasingly high requirements of automobile piston sealing rings, the aging of rubber rings, and the increase of maintenance costs, etc. Tear resistance, reduce internal stress, improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

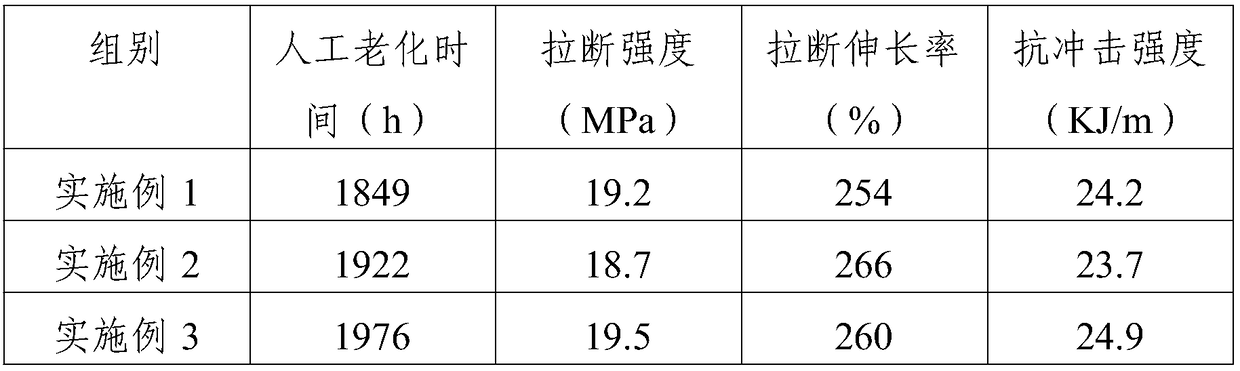

Embodiment 1

[0025] A rubber for a piston sealing ring with good aging resistance, the rubber for the sealing ring is made of the following raw materials in parts by weight: 60 parts of natural rubber, 40 parts of isoprene rubber, 20 parts of acrylate rubber, polyvinylidene chloride 14 parts, 2 parts of p-trifluoromethylbenzonitrile, 10 parts of glass fiber, 3 parts of titanium dioxide, 4 parts of nano-zinc oxide, 2 parts of paraffin, 1 part of sulfur, 4 parts of phthalimide, 1 part of coupling agent, lubrication 6 parts of anti-aging agent and 4 parts of anti-aging agent.

[0026] Wherein, the coupling agent is a monoalkoxy titanate coupling agent; the lubricant is silicone oil; the anti-aging agent is 2,6-tertiary butyl-4-methylphenol, thio A mixture of diester dipropionate and 1,2,3-benzotriazole in a mass ratio of 5:3:3.

[0027] The preparation method of rubber for the piston sealing ring comprises the following steps:

[0028] (1) Mixing natural rubber, isoprene rubber and acrylate...

Embodiment 2

[0034] A rubber for a piston sealing ring with good aging resistance, the rubber for the sealing ring is made of the following raw materials in parts by weight: 80 parts of natural rubber, 50 parts of isoprene rubber, 30 parts of acrylate rubber, polyvinylidene chloride 20 parts, 5 parts of p-trifluoromethylbenzonitrile, 12 parts of glass fiber, 5 parts of titanium dioxide, 6 parts of nano-zinc oxide, 3 parts of paraffin, 3 parts of sulfur, 6 parts of phthalimide, 3 parts of coupling agent, lubrication 8 parts of anti-aging agent and 5 parts of anti-aging agent.

[0035] Wherein, the coupling agent is a monoalkoxy titanate coupling agent; the lubricant is silicone oil; the anti-aging agent is 2,6-tertiary butyl-4-methylphenol, thio A mixture of diester dipropionate and 1,2,3-benzotriazole in a mass ratio of 5:3:3.

[0036] The preparation method of rubber for the piston sealing ring comprises the following steps:

[0037] (1) Mixing natural rubber, isoprene rubber and acryla...

Embodiment 3

[0043] A rubber for a piston sealing ring with good aging resistance effect, the rubber for the sealing ring is made of the following raw materials in parts by weight: 70 parts of natural rubber, 45 parts of isoprene rubber, 25 parts of acrylate rubber, polyvinylidene chloride 17 parts, 4 parts of p-trifluoromethylbenzonitrile, 11 parts of glass fiber, 4 parts of titanium dioxide, 5 parts of nano-zinc oxide, 2.5 parts of paraffin, 2 parts of sulfur, 5 parts of phthalimide, 2 parts of coupling agent, lubrication 7 parts of anti-aging agent and 4.5 parts of anti-aging agent.

[0044] Wherein, the coupling agent is a monoalkoxy titanate coupling agent; the lubricant is silicone oil; the antiaging agent is 2,6-tertiary butyl-4-methylphenol, thio A mixture of diester dipropionate and 1,2,3-benzotriazole in a mass ratio of 5:3:3.

[0045] The preparation method of the rubber for the piston sealing ring comprises the following steps:

[0046] (1) Mixing natural rubber, isoprene rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com