Composite material for ship shore power cable insulating layer, and preparation method thereof

A composite material and cable insulation technology, applied to rubber insulators, organic insulators, etc., can solve problems such as shortened cable life, and achieve good mechanical strength, multiple functions, superior heat resistance and aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

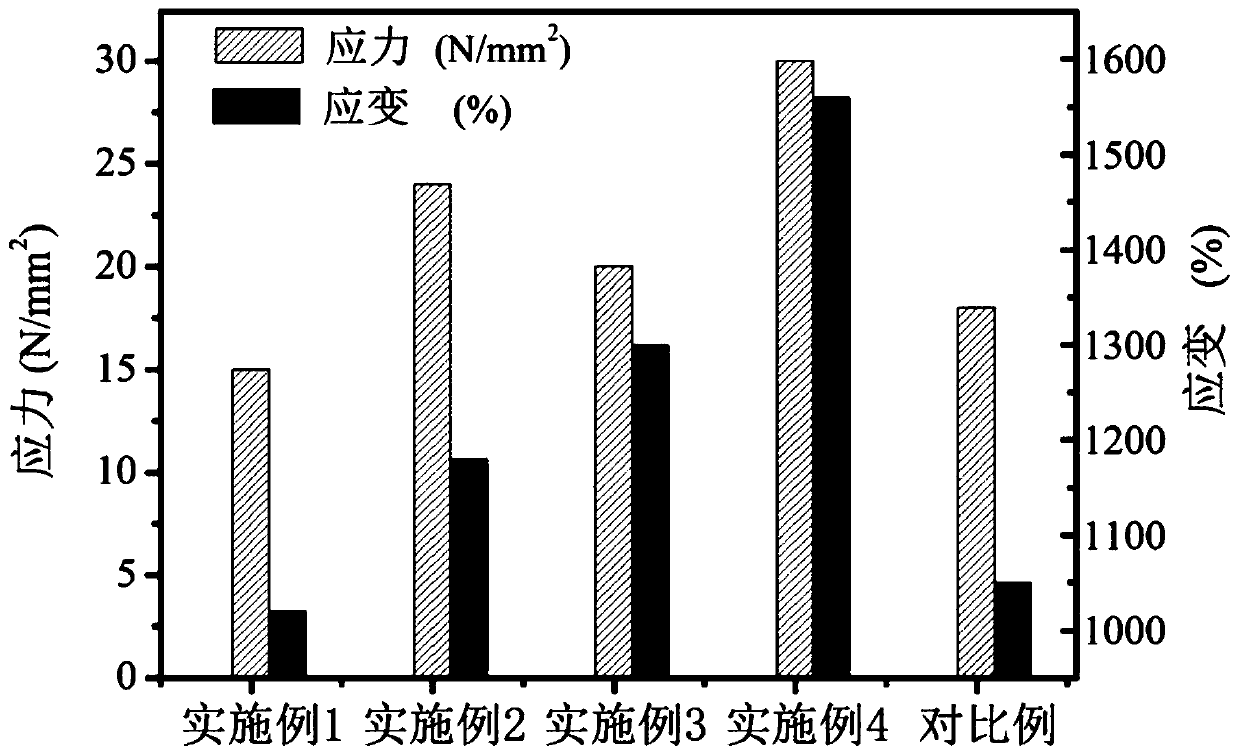

[0036] Composite material test method is as follows in the specific embodiment:

[0037] Stress and strain: tested according to GB / T 8815 standard

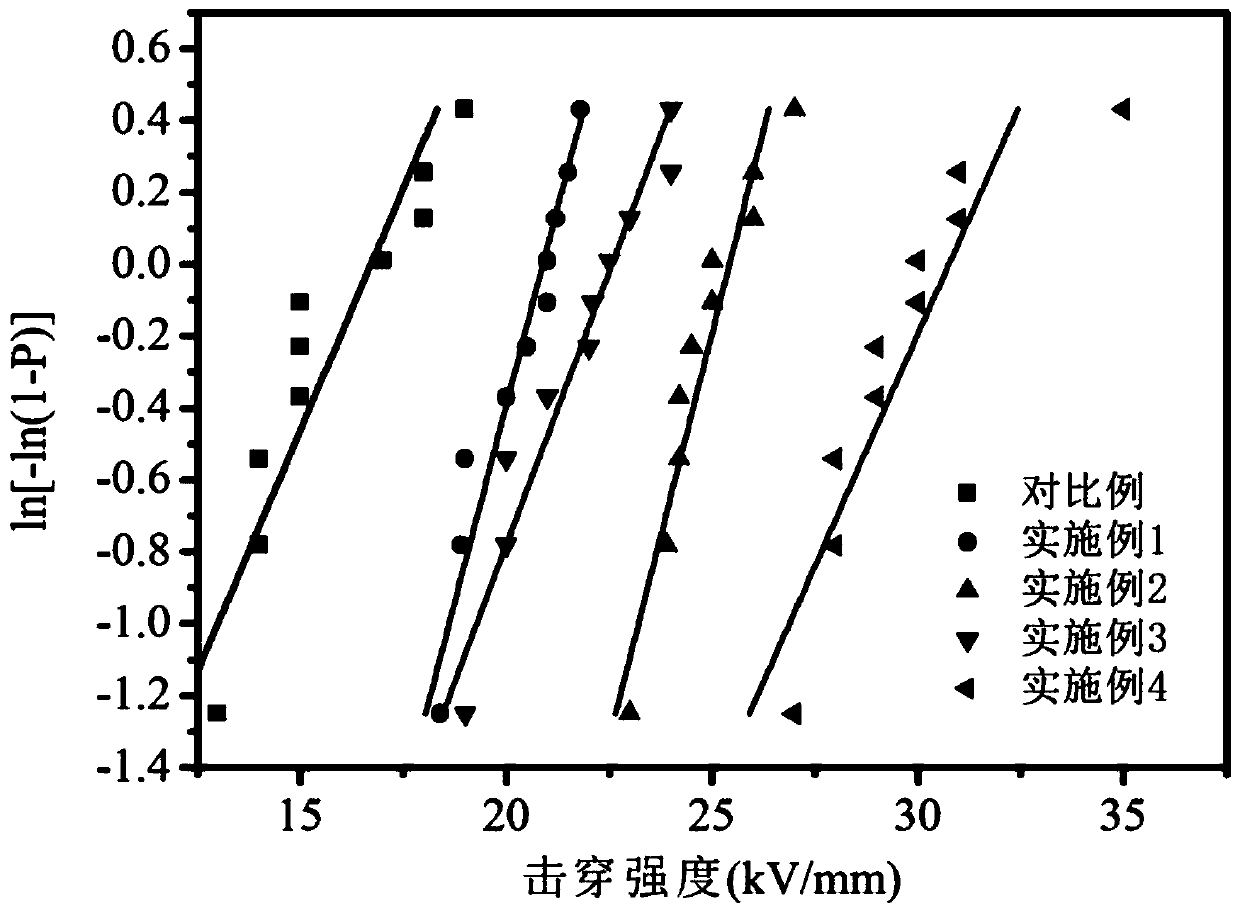

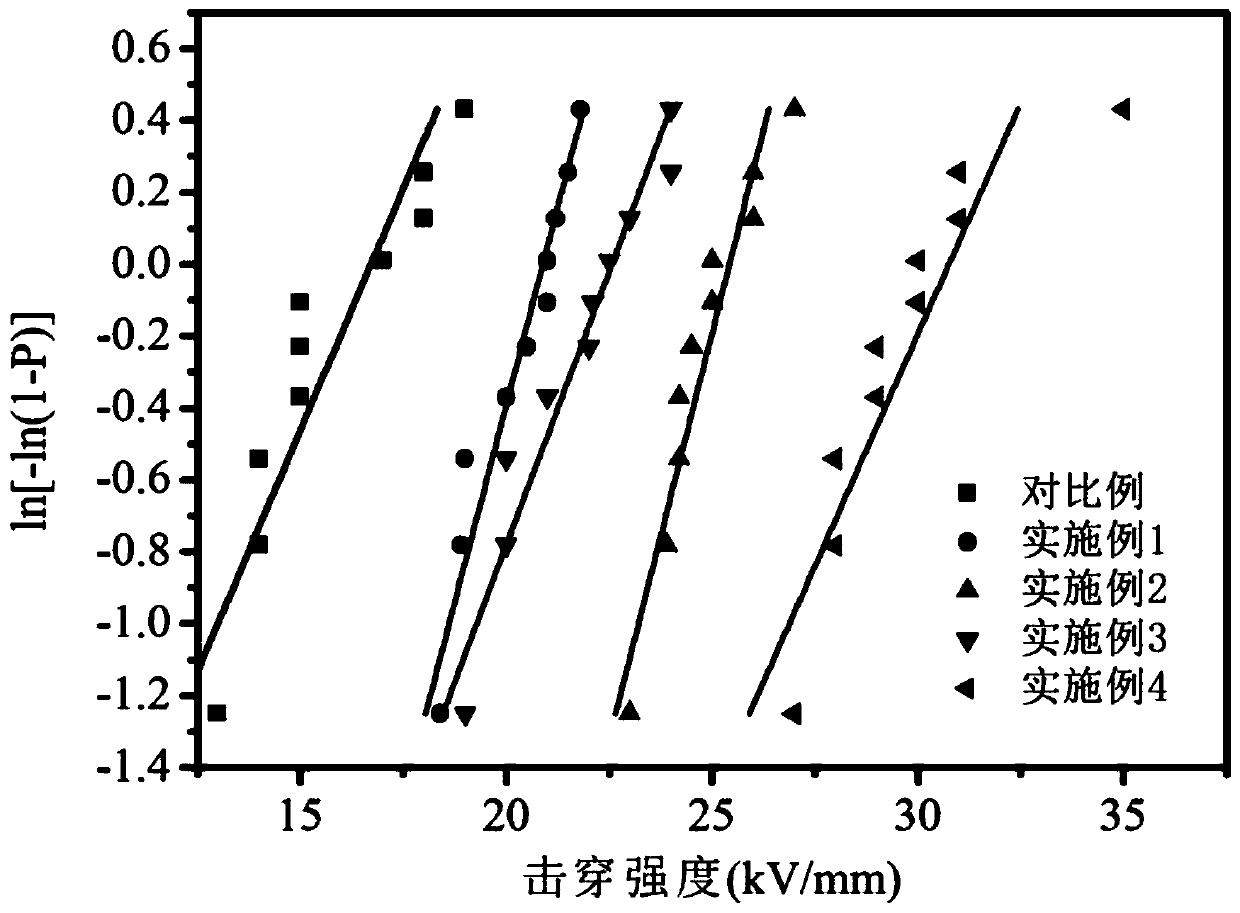

[0038] Breakdown strength: tested according to GB / T 1408.1-2006 standard, sample thickness is 1mm±0.1mm. According to the weibull distribution data processing method, the obtained data is processed and plotted, such as figure 2 shown.

[0039] Dielectric constant: The sample is made into a small piece with a diameter of 1cm2, and the front and back sides are coated with silver electrodes, and the material is tested by an impedance analyzer (ESPEC CORP SU-261) at a frequency of 102Hz-106Hz at room temperature. test.

[0040] Measurement of volume resistivity: according to the GB / T 1408.1-2006 standard test, the sample thickness is 2mm±0.1mm, and the test voltage is 100V.

Embodiment 1

[0042] EPDM insulation layer material for ship shore power cables, the components and their mass parts in the raw materials are:

[0043] 10 parts of low-density polyethylene, 90 parts of EPDM rubber, 3 parts of nano-zinc oxide, 0.6 parts of stearic acid, 0.6 parts of 2-mercaptobenzimidazole, 0.3 parts of triallyl isocyanurate TAIC, white carbon 18 parts of black, 0.6 parts of sulfur powder, 2.1 parts of dicumyl peroxide DCP, 19 parts of white oil. The particle size of the nano zinc oxide is 50±10nm;

[0044] Concrete preparation operation is as follows:

[0045] (1) Weigh the raw materials according to the weight of the ingredients in the formula, mix all the raw materials evenly, then raise the temperature of the rheometer to 100°C, and the speed is 60r / min, then add the mixed raw materials, and then seal the mixing tank , making the materials melt and blend in the blending tank for 10 minutes;

[0046] (2) After the torque of the material in the rheometer reaches the equ...

Embodiment 2

[0052] EPDM insulation layer material for ship shore power cables, the components and their parts by mass are:

[0053] 30 parts of low-density polyethylene, 70 parts of EPDM rubber, 3 parts of nano-zinc oxide, 0.6 parts of stearic acid, 0.6 parts of 2-mercaptobenzimidazole, 0.3 parts of triallyl isocyanurate TAIC, 18 parts of white carbon black, 0.6 parts of sulfur powder, 2.1 parts of DCP, 20 parts of white oil. The particle size of the nano zinc oxide is 50±10nm;

[0054] Concrete preparation operation is as follows:

[0055] (1) Weigh the raw materials according to the weight of the ingredients in the formula, mix all the raw materials evenly, then raise the temperature of the rheometer to 100°C, and the speed is 60r / min, then add the mixed raw materials, and then seal the mixing tank , making the materials melt and blend in the blending tank for 10 minutes;

[0056] (2) After the torque of the material in the rheometer reaches the equilibrium value, the EPDM / LDPE compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Breakdown strength | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com