Room-temperature-cured bi-component epoxy adhesive with high heat resistance and high peel strength

An epoxy adhesive, room temperature curing technology, applied in epoxy resin glue, modified epoxy resin adhesive, non-polymer adhesive additives, etc., can solve problems affecting aging resistance, strength attenuation, etc. , to achieve the effects of high cost performance, increased strength, and good heat and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

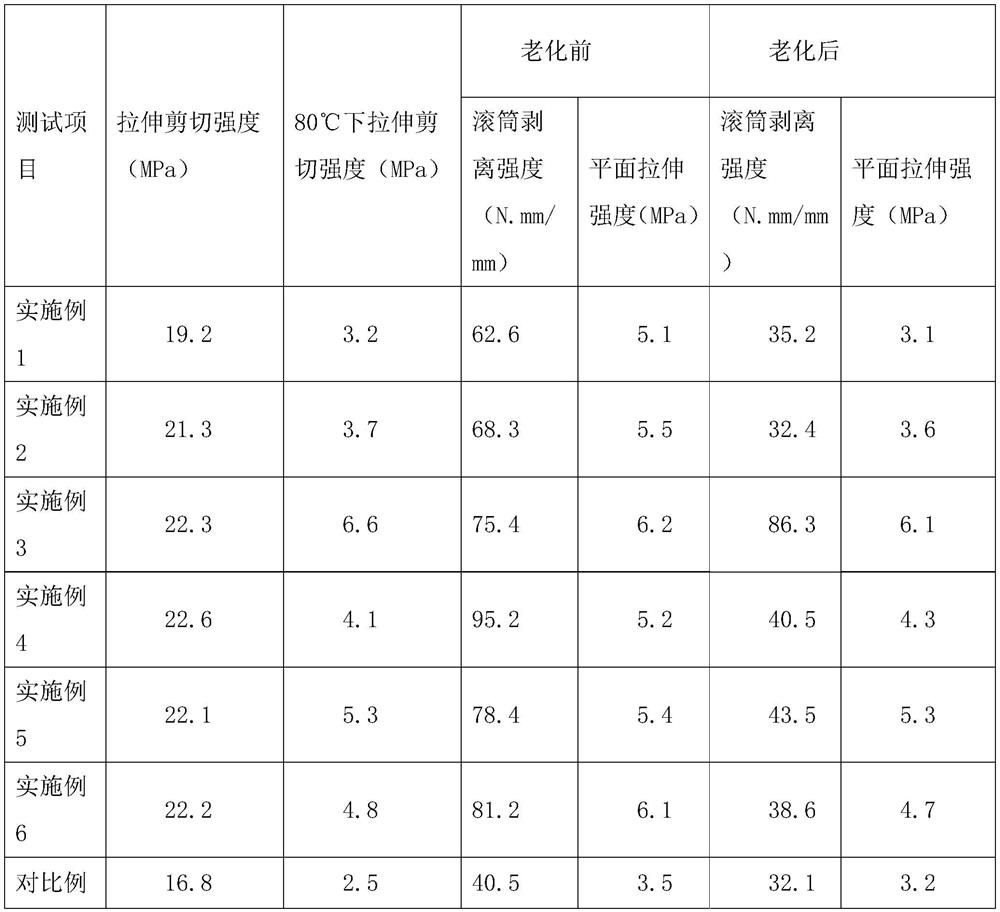

Examples

Embodiment 1

[0024] (1) Preparation of component A:

[0025] ① 45 parts by weight of bisphenol A epoxy resin, 13 parts by weight of self-made acrylic modified epoxy resin, 12 parts by weight of core-shell toughened particles, 10 parts by weight of reactive diluent, 2 parts by weight of silane coupling agent and 0.2 parts by weight Add the wetting and dispersing agent in parts by weight to the planetary stirring tank in turn, raise the temperature of the material to 60°C, and at the same time, slowly increase the planetary stirring to 60-70rpm, slowly accelerate the high-speed dispersion to 800-900rpm, vacuum defoaming for 15-20min Then turn off the planetary stirring and high-speed dispersion.

[0026] ②Add 27.8 parts by weight of filler to the planetary stirring tank, slowly increase the planetary stirring to 60-70rpm, and slowly accelerate the high-speed dispersion to 800-900rpm, turn off the planetary stirring and high-speed dispersion after vacuum defoaming for 45-50min, Feed to get A...

Embodiment 2

[0031] (1) Preparation of component A:

[0032] ① 42 parts by weight of bisphenol A epoxy resin, 16 parts by weight of self-made acrylic modified epoxy resin, 3 parts by weight of core-shell toughened particles, 9 parts by weight of reactive diluent, 2 parts by weight of silane coupling agent and 0.3 parts by weight Add the wetting and dispersing agent in parts by weight to the planetary stirring tank in turn, raise the temperature of the material to 60°C, and at the same time, slowly increase the planetary stirring to 60-70rpm, slowly accelerate the high-speed dispersion to 800-900rpm, vacuum defoaming for 15-20min Then turn off the planetary stirring and high-speed dispersion.

[0033] ②Add 27.7 parts by weight of filler to the planetary stirring tank, slowly increase the planetary stirring to 60-70rpm, and slowly accelerate the high-speed dispersion to 800-900rpm, turn off the planetary stirring and high-speed dispersion after vacuum defoaming for 45-50min, and the Feed to...

Embodiment 3

[0038] (1) Preparation of component A:

[0039] ① Mix 40 parts by weight of bisphenol A epoxy resin, 16 parts by weight of self-made acrylic modified epoxy resin, 9 parts by weight of core-shell toughened particles, 10 parts by weight of reactive diluent, 2 parts by weight of silane coupling agent and 0.4 parts by weight Add the wetting and dispersing agent in parts by weight to the planetary stirring tank in turn, raise the temperature of the material to 60°C, and at the same time, slowly increase the planetary stirring to 60-70rpm, slowly accelerate the high-speed dispersion to 800-900rpm, vacuum defoaming for 15-20min Then turn off the planetary stirring and high-speed dispersion.

[0040] ② Add 22.6 parts by weight of filler to the planetary stirring tank, slowly increase the planetary stirring to 60-70rpm, and slowly accelerate the high-speed dispersion to 800-900rpm, turn off the planetary stirring and high-speed dispersion after vacuum defoaming for 45-50min, and the F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com