Electric power engineering construction tool box and preparation method thereof

A construction tool and power engineering technology, applied in the field of power equipment, can solve the problems of insulation performance, flame retardant performance and mechanical strength that cannot meet the requirements, and achieve the effects of improving resin compatibility, low production cost, and improving thermal conductivity and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A power engineering construction tool box, which includes a box body, and the box body is prepared according to the following method:

[0020] Step 1) ball milling, step 2) crushing and grinding, step 3) resin modification, step 4) calcining and mixing, step 5) stirring, melting and injection molding;

[0021] Specifically, the box body is prepared according to the following method:

[0022] Step 1) Ball milling: Mix borax, silicon carbide and active agent evenly according to the mass ratio of 50:30:1, and put them into the ball milling tank. The ball milling time is 6 hours, the ball mill speed is 1000 rpm, and the ball milling is until the powder particle size is 200 meshes to obtain mixture 1;

[0023] Step 2) Crushing and grinding: add perlite and sepiolite to the crusher at a mass ratio of 2:1 for crushing, and then grind to obtain a powder with a particle size of 200 meshes, which is the mixture 2;

[0024] Step 3) Resin modification: add Mixture 1, Mixture 2, a...

Embodiment 2

[0029] A power engineering construction tool box, which includes a box body, and the box body is prepared according to the following method:

[0030] Step 1) ball milling, step 2) crushing and grinding, step 3) resin modification, step 4) calcining and mixing, step 5) stirring, melting and injection molding;

[0031] Specifically, the box body is prepared according to the following method:

[0032] Step 1) Ball milling: Mix borax, silicon carbide and active agent evenly according to the mass ratio of 50:30:1, and put them into the ball milling tank. The ball milling time is 6 hours, the ball mill speed is 1000 rpm, and the ball milling is until the powder particle size is 200 meshes to obtain mixture 1;

[0033] Step 2) Crushing and grinding: add perlite and sepiolite to the crusher at a mass ratio of 2:1 for crushing, and then grind to obtain a powder with a particle size of 200 meshes, which is the mixture 2;

[0034] Step 3) Resin modification: add Mixture 1, Mixture 2, a...

Embodiment 3

[0039] Box material performance test of the present invention:

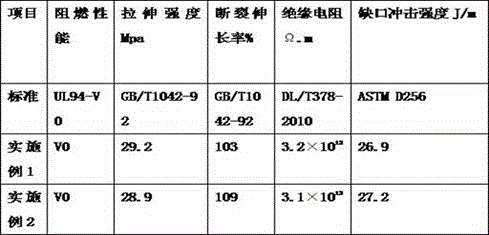

[0040] 1. The box body material prepared in embodiment 1-2 is made standard test piece according to test standard, carries out following performance test, and the results are shown in Table 1:

[0041] Table 1

[0042]

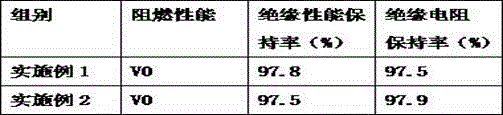

[0043] 2. Corrosion resistance test: Take salt solution as an example, soak the test material in 10% sodium chloride solution for 240 hours, and measure the main performance parameters, see Table 2:

[0044] Table 2

[0045] group Flame retardant properties Insulation performance retention rate (%) Tensile strength retention (%) Elongation at break (%) Example 1 V0 96.3 98.7 98.1 Example 2 V0 96.2 98.9 98.3

[0046] 3. High temperature resistance performance test: The performance test of the box material prepared in Examples 1 and 2 under high temperature conditions: the selected temperature is 90°C, and the cable material is placed at this temperature fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com