Chlorobutyl-butyronitrile glue-spraying adhesive for inside decorative material for vehicle and preparation method thereof

An adhesive and neoprene technology, which is used in the field of glue-sprayed chloroprene-nitrile adhesives for vehicle interior materials, can solve the problems of poor aging resistance of adhesives, high apparent viscosity of adhesives, and high aging resistance. , to achieve the effect of low toxicity, fast drying speed, good heat resistance and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

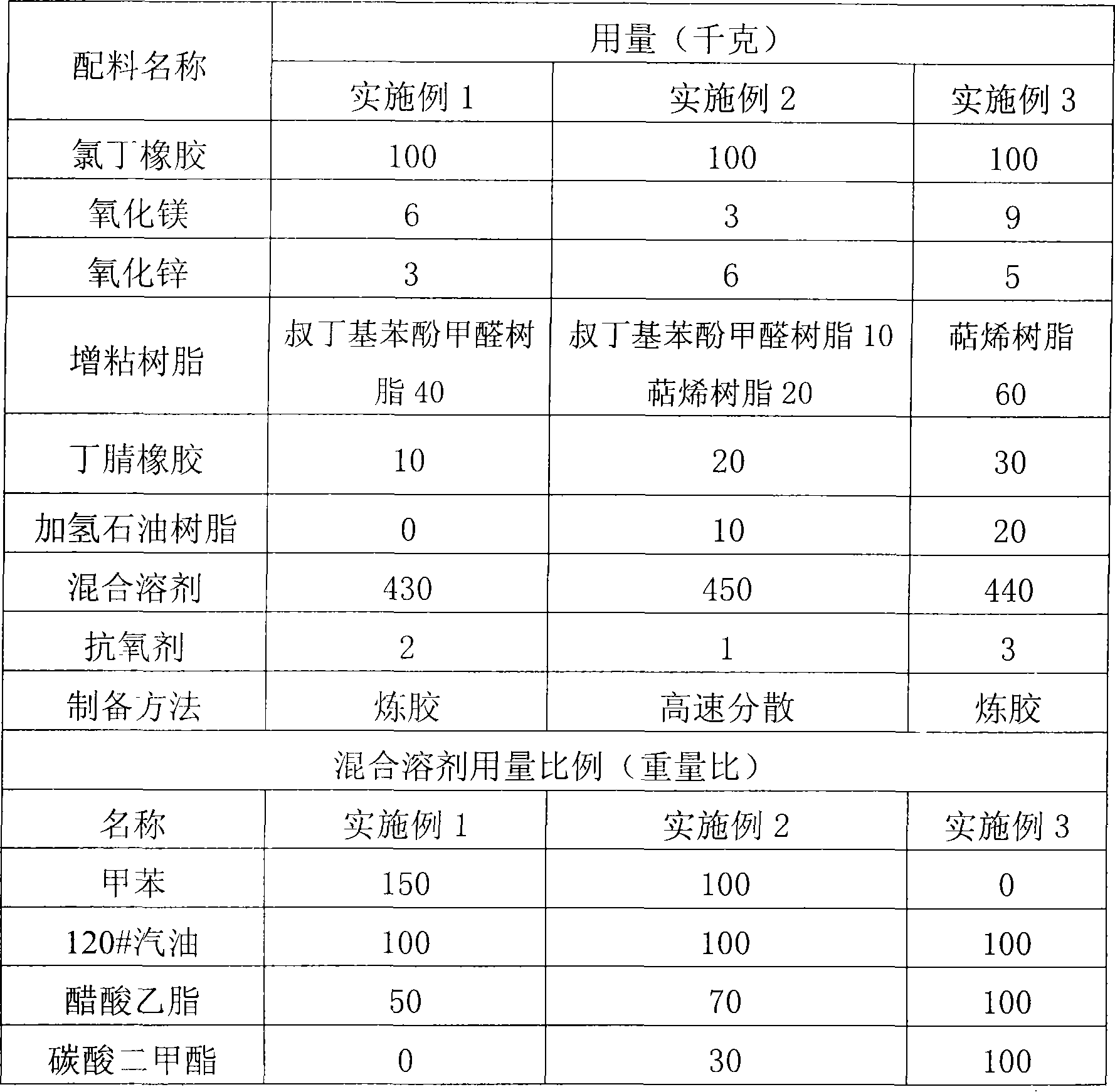

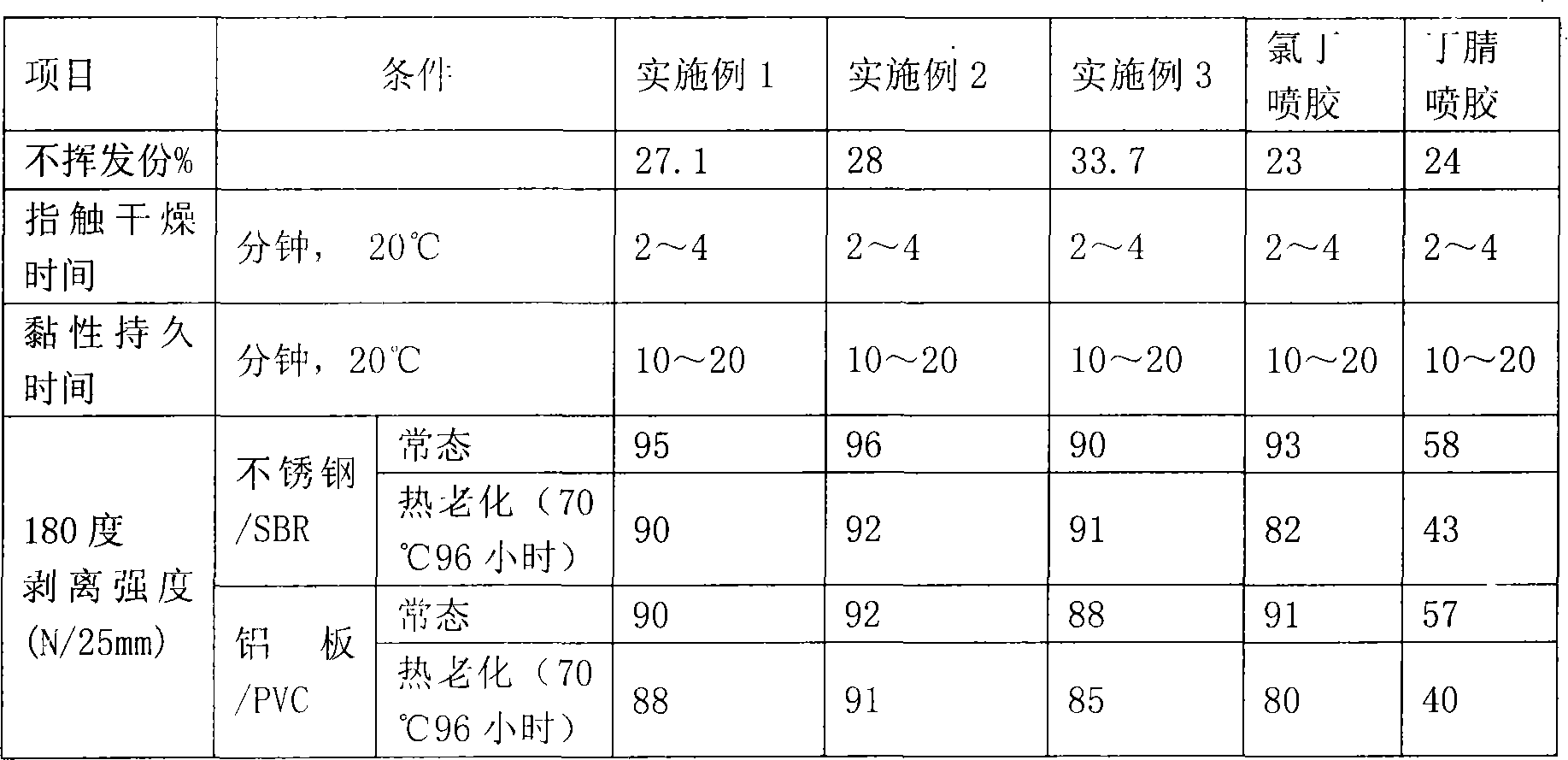

[0024] The vehicle interior material spray type chloroprene-nitrile adhesive of the present invention is to be with chloroprene rubber and nitrile rubber, tackifying resin, by weight ratio 100: 10~30: 20~60 blending, and add magnesium oxide, oxidation Zinc, formed by reacting at 20-60°C.

[0025] The raw materials used in the present invention have:

[0026] Neoprene: Highly crystalline non-sulfur-adjusted neoprene, fast crystallization bonding type, with strong initial adhesion; you can directly choose neoprene with a Mooney viscosity of 17-23, or choose a Mooney viscosity of 60-60. 80 chloroprene rubber (when in use, its molecular weight needs to be reduced through rubber mixing, so that its Mooney viscosity is reduced by about 10% on the original basis, generally 20-50). In the present invention, the Mooney viscosity of chloroprene rubber is reduced by mastication or high-speed dispersion; mastication is to thinly pass the rubber on the rubber mixer, and the roller distanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com