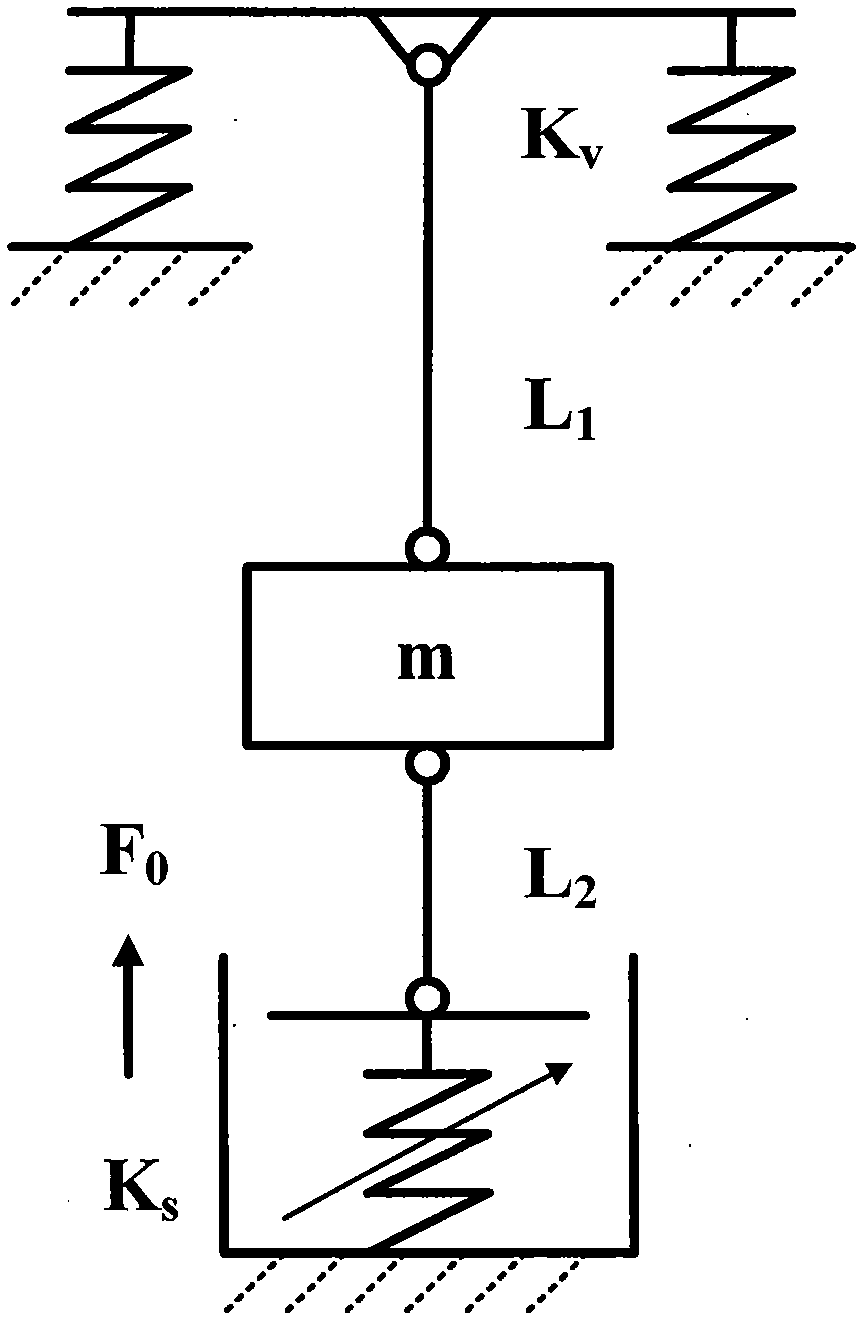

Pneumatic spring vibration isolator of air flotation type forward and backward swing concatenation mechanism based on ball head connecting rod

A technology of air springs and ball-end connecting rods, which is used in gas shock absorbers, springs/shock absorbers, mechanical equipment, etc., to achieve the effects of compact structure, improved comprehensive vibration isolation performance, and good vibration isolation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

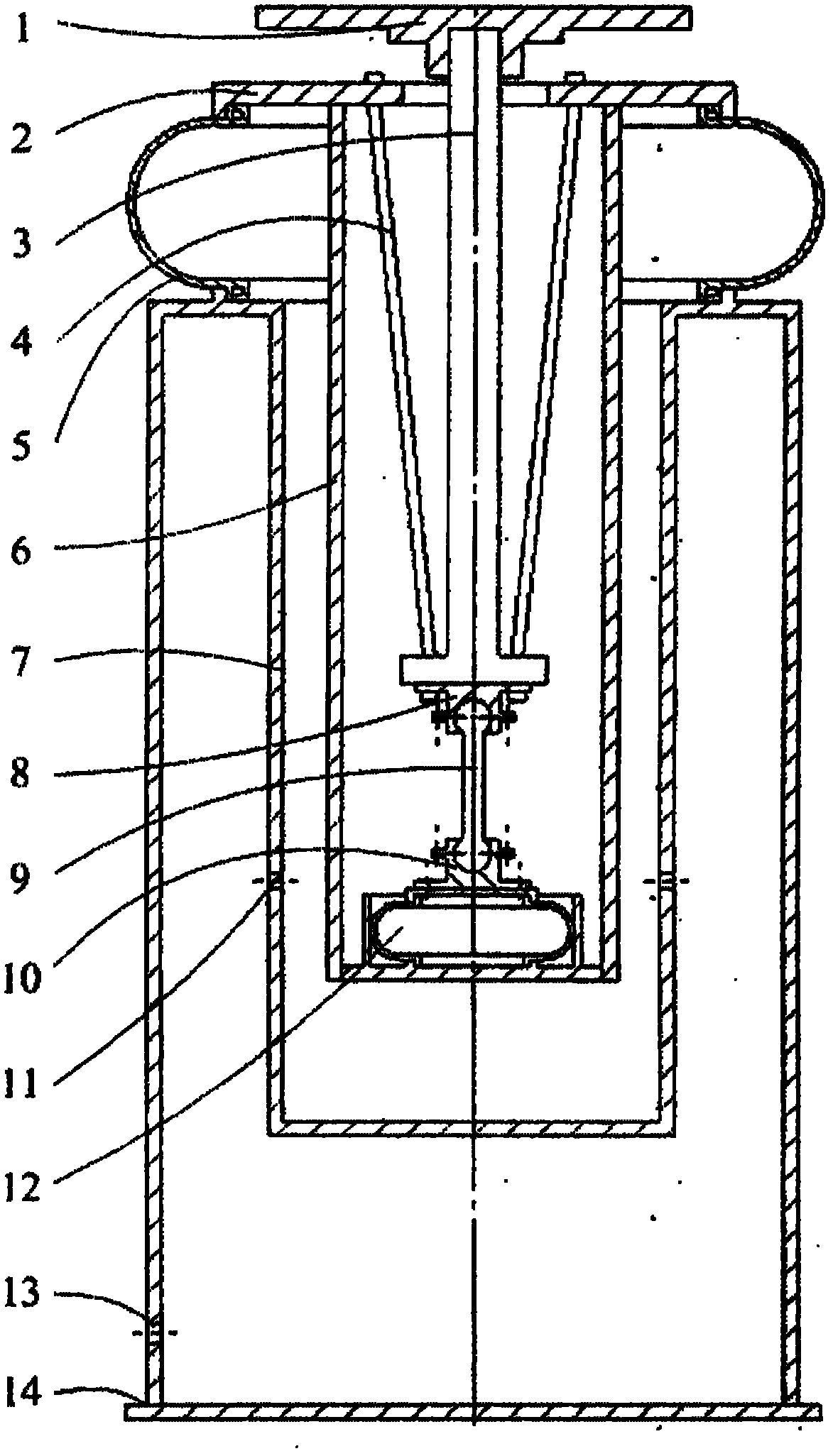

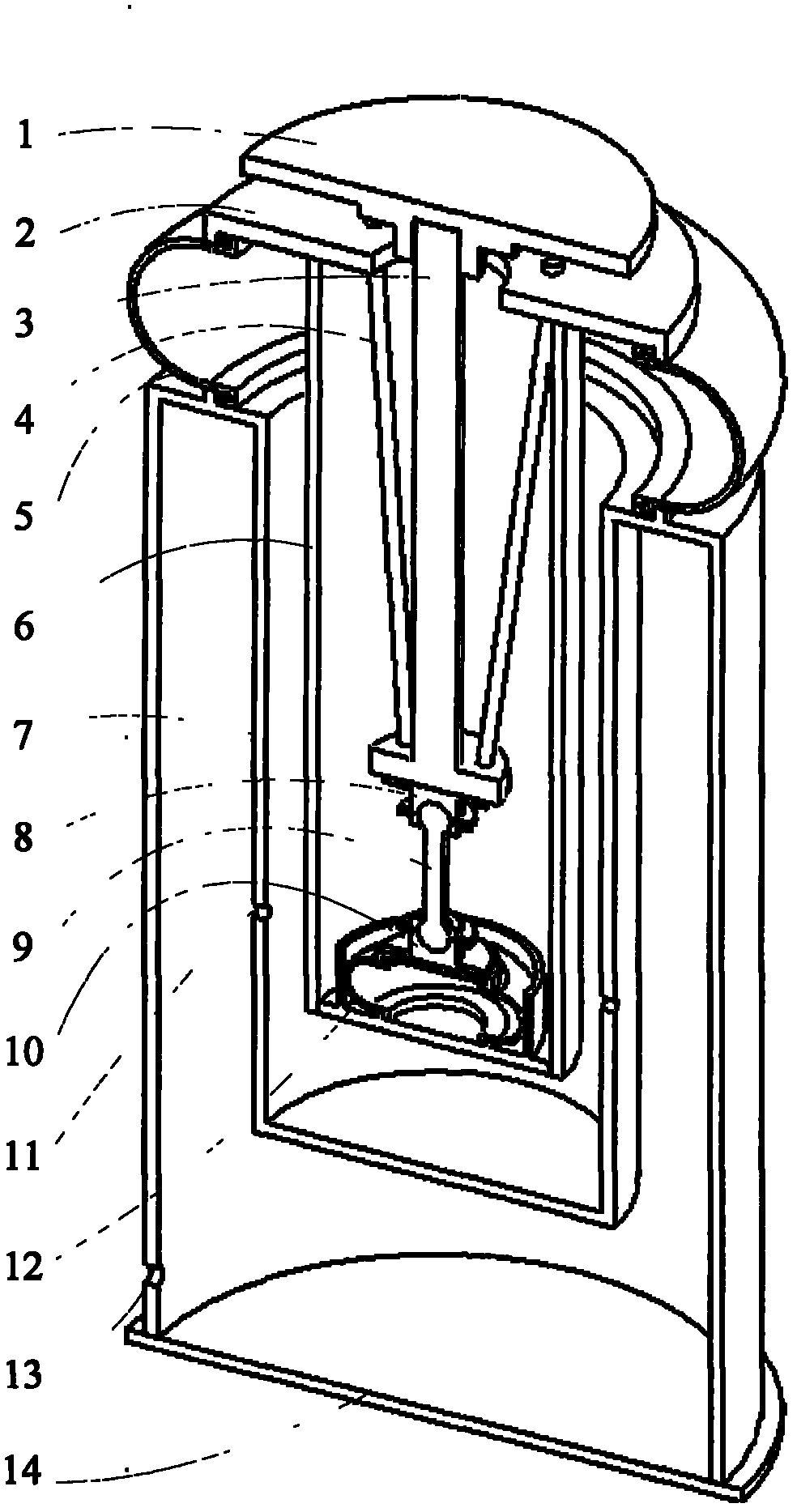

[0036] Specific embodiments of the present invention are described in detail below in conjunction with accompanying drawings, as figure 2 , image 3 and Figure 4 As shown, an embodiment of the air spring isolator of the present invention is shown.

[0037] The air spring vibration isolator is equipped with an inner cylinder 6 inside the outer cylinder 7, and the air spring airbag 5 is set outside the upper end of the inner cylinder 6. The outer cylinder 7 is sealed and connected with the lower end of the air spring airbag 5 through its upper end boss, and the inner cylinder 6 The annular cover plate 2 affixed to its upper end is sealed and connected with the upper end of the air spring airbag 5 , the air inlet 13 is arranged on the outer wall of the outer cylinder 7 , and a group of throttle holes 11 arranged in a circle are arranged on the inner wall of the outer cylinder 7 . The lower end is sealed and equipped with a circular bottom plate 14, and the support rod 3 passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com