Shock absorption assembly of engine

An engine and assembly technology, applied in the direction of power plant, jet propulsion device, internal combustion propulsion device, etc., can solve the problem of unreasonable design and structure of the engine shock absorber assembly, improve the consistency and compression performance, and improve the vibration isolation performance , the effect of convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

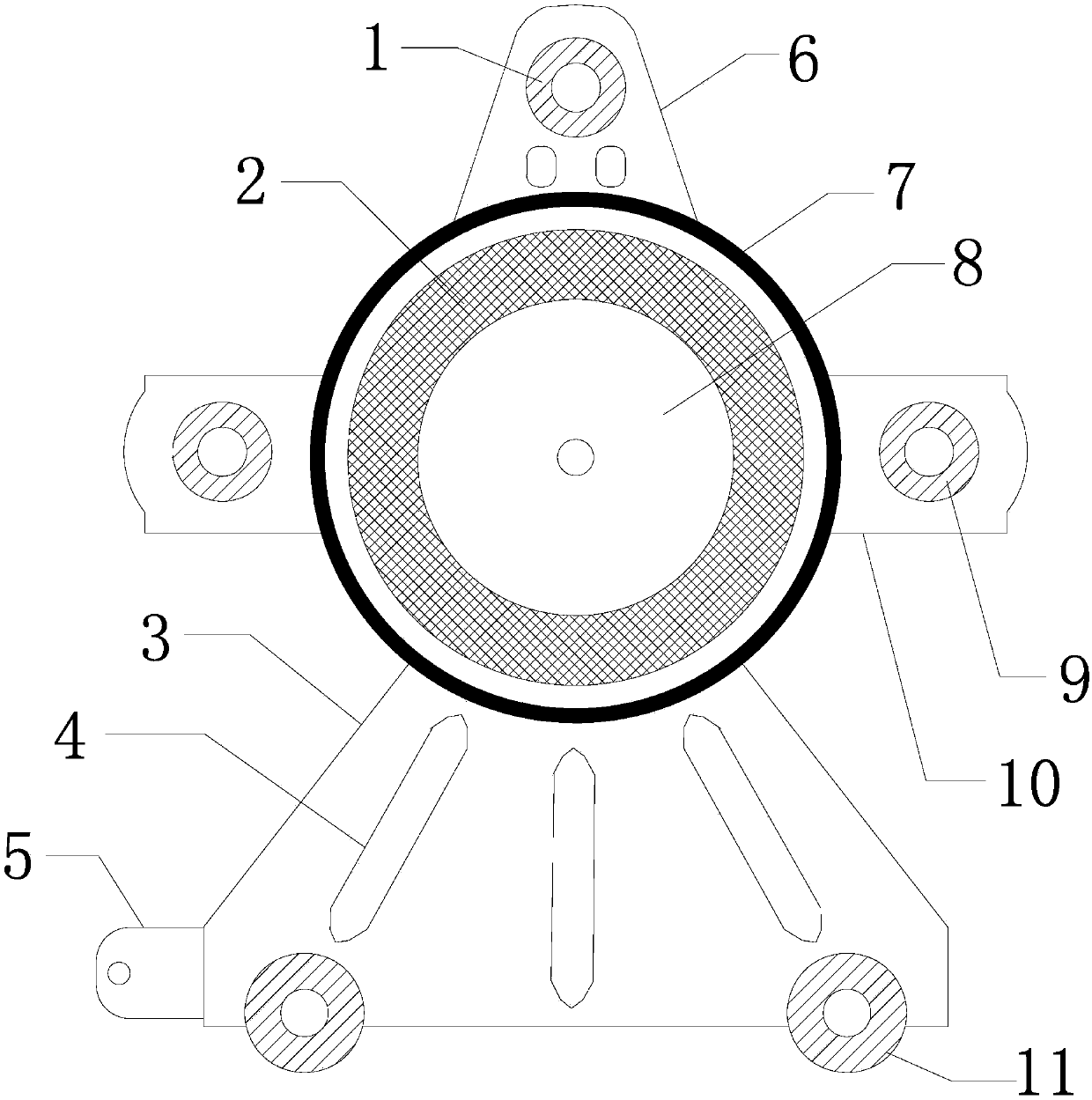

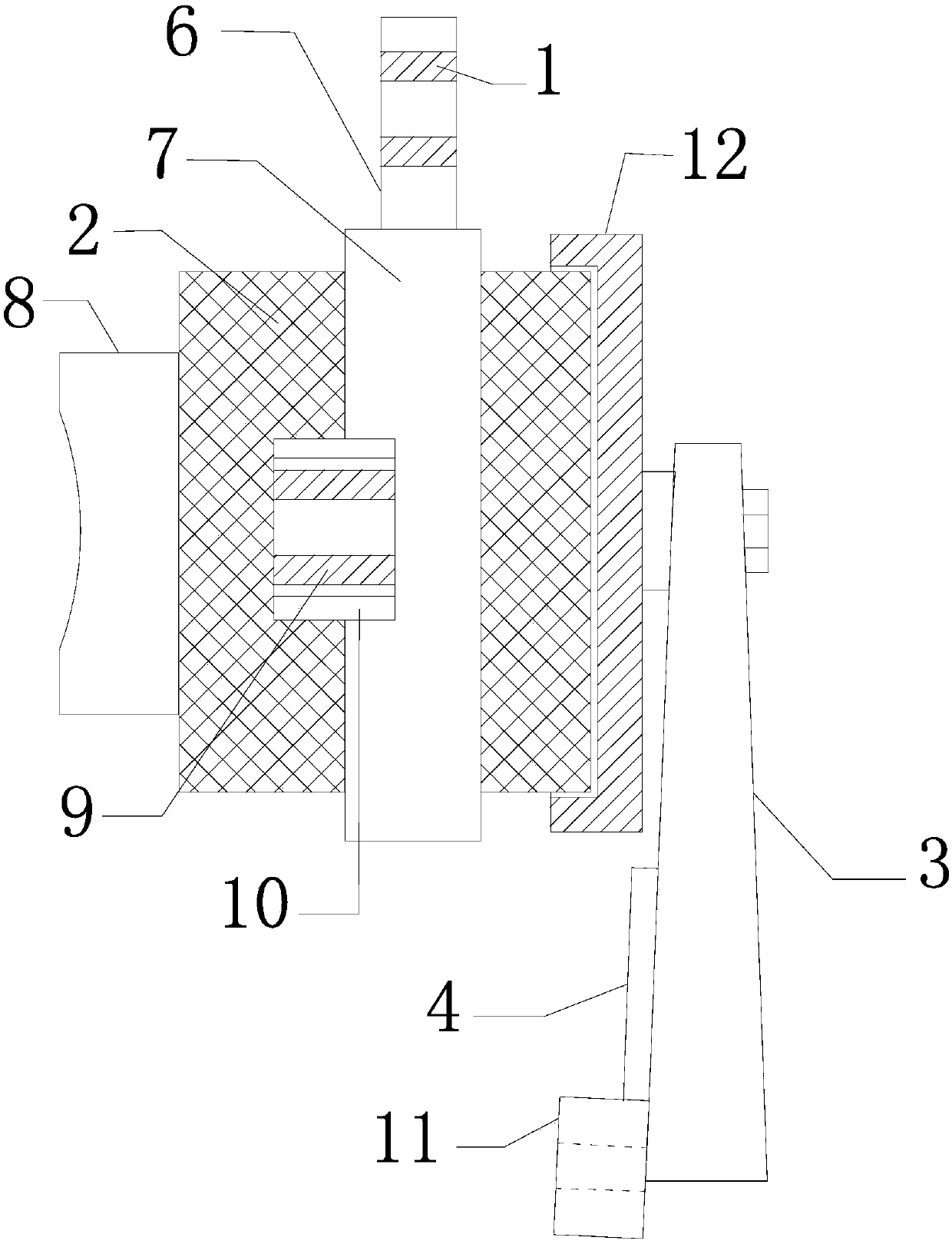

[0014] The engine damping assembly of the present invention includes a first titanium alloy ring 1, a metal sleeve 2, a lower plate frame 3, a reinforcing rib 4, a protruding plate 5, a top frame 6, an outer casing 7, a shock absorbing ring 8, and a second titanium alloy ring. Alloy ring 9, side frame 10, mounting groove 11 and protective sleeve 12, the shock absorbing ring 8 is installed in the metal sleeve 2, and the metal sleeve 2 is installed in the outer sleeve 7, and the top of the outer sleeve 7 is provided with a 7 integrally connected top frame 6, the first titanium alloy ring 1 is installed in the top frame 6, the left and right sides of the outer sleeve 7 are respectively provided with side frames 10 integrally connected with the outer sleeve, and the second titanium alloy ring is installed in the side frame 10 9. The right end of the metal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com