Micro electro mechanical system (MEMS) centrifugal safety mechanism for rotating ammunition and safety method thereof

A technology for centrifugal insurance and ammunition, applied in weapon accessories, fuzes, offensive equipment, etc., can solve the problems of large occupied space, limit the miniaturization of security devices, and cumbersome assembly links, so as to facilitate modularization, reduce assembly links, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

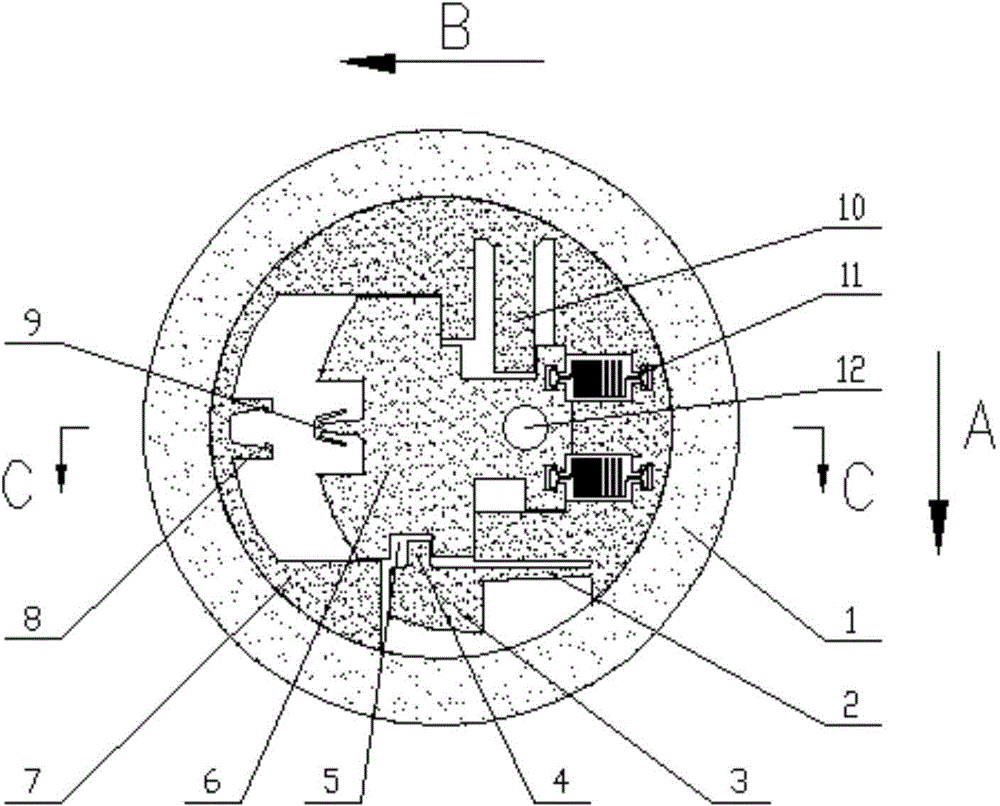

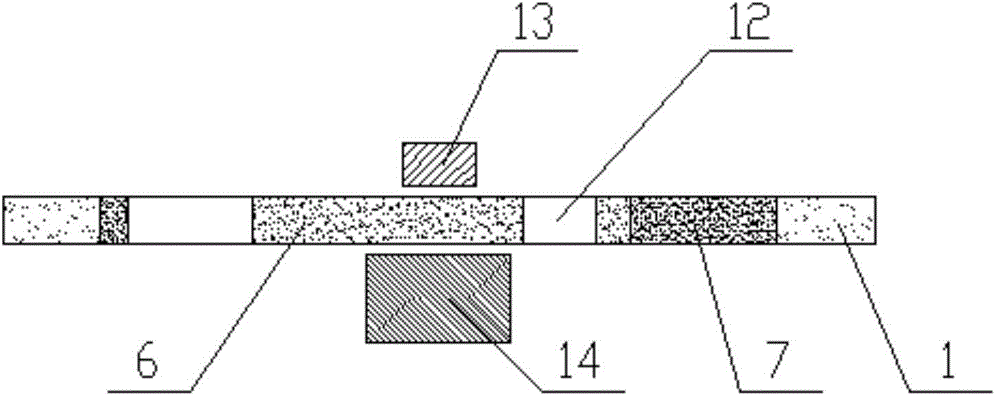

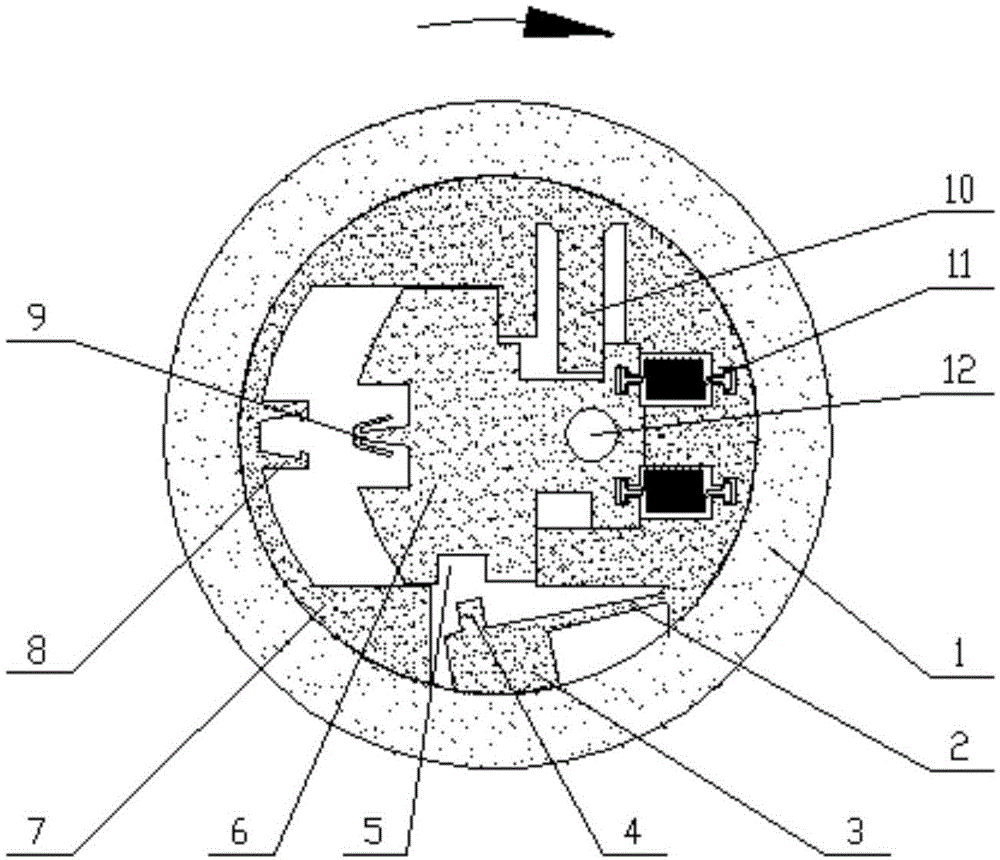

[0032] As shown in Figure 1, in this embodiment, the security device includes a slider 6, a base plate 7, a deck 8, a chuck 9, a locking baffle 10, a spring 11 and a blast hole 12 inside the fuze body 1; , the substrate 7 is arranged on the inner surface of the fuze body 1, and one end of the substrate 7 is equipped with a spring 11, which adopts a MEMS spring, and the other is provided with a deck 8; one end of the slider is connected to the substrate by a spring, and the other end of the slider is connected to the deck The corresponding position is provided with a chuck; the top of the slider is provided with a top groove, and the locking baffle arranged on the top of the substrate is embedded into the top of the slider through the baffle groove; and a blast hole is provided on the slider. In the service processing state, the blast hole is isolated from the blast channel, as shown in Figure 1(b).

[0033] As shown in Figure 1(b), the security device in the fuze is located be...

Embodiment 2

[0037] In the first embodiment, the shape of the centrifugal baffle plate 4 is rectangular, and the groove 5 at the bottom of the slider is correspondingly also rectangular. In this example, if Figure 4 As shown, the top side of the centrifugal baffle 4 has a protrusion, the bottom groove 5 and the centrifugal baffle are complementary figures, and the side also has a protrusion correspondingly, so as to better ensure the restraint performance of the centrifugal safety mechanism on the slider 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com