Multidimensional force/torque sensor

A torque sensor and multi-dimensional force technology, applied in the field of sensors, can solve problems such as reducing the detection dimension of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

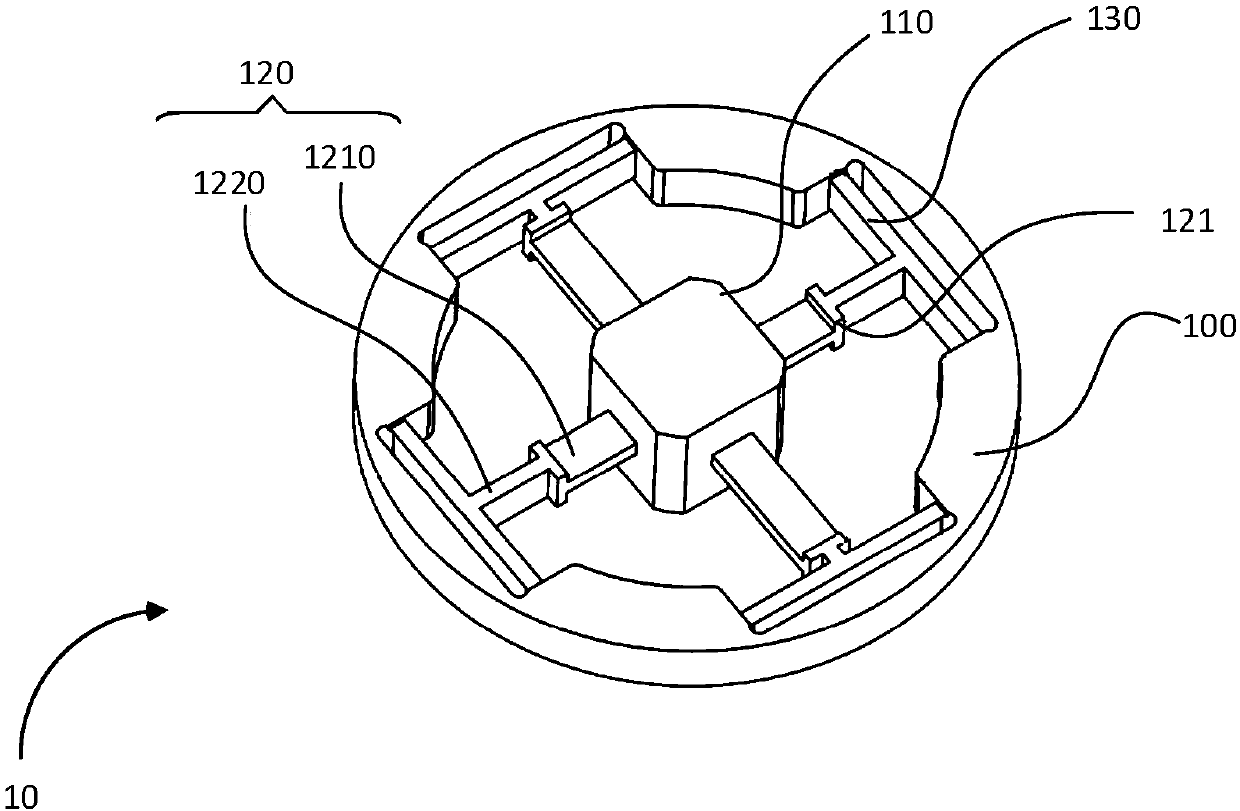

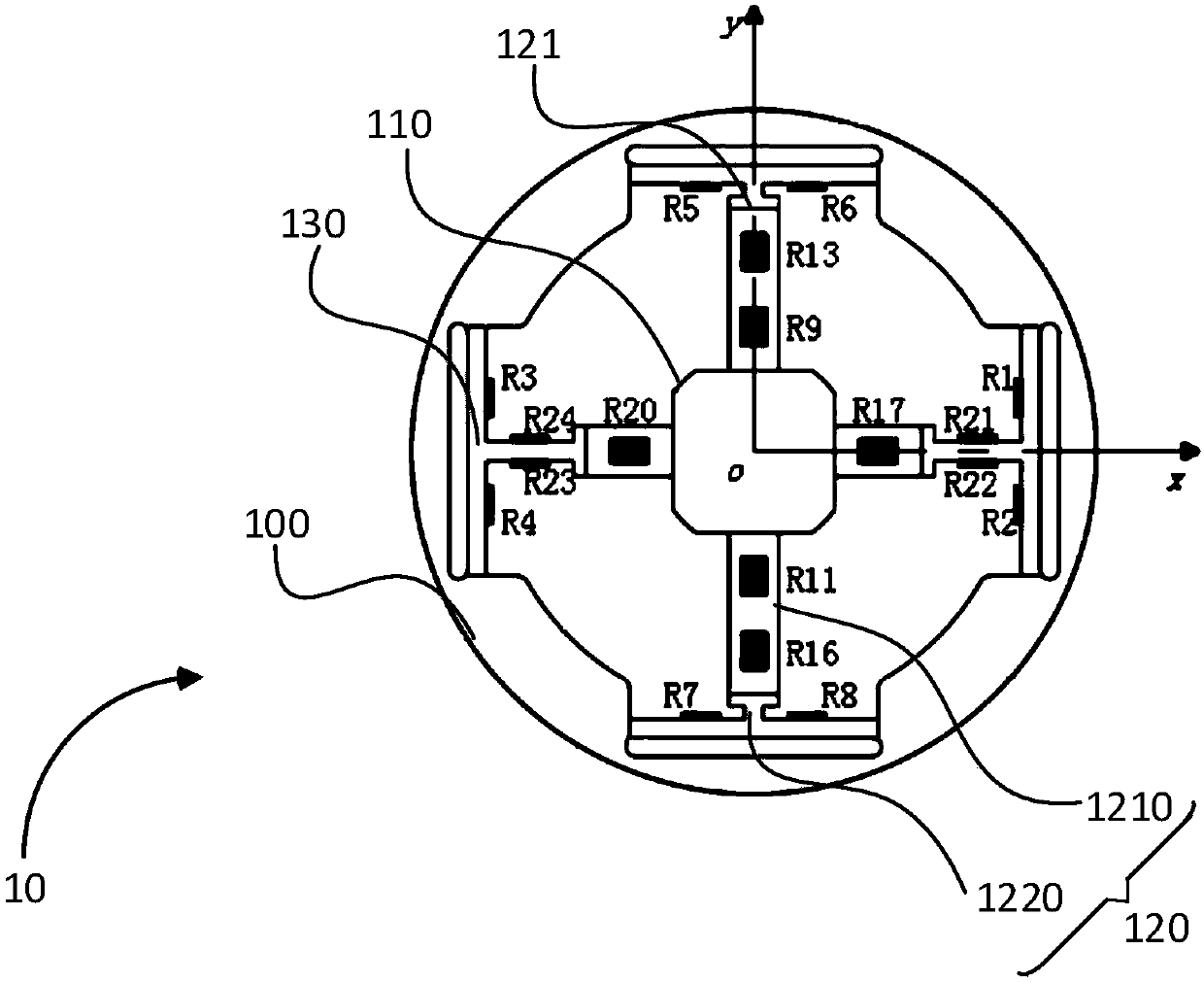

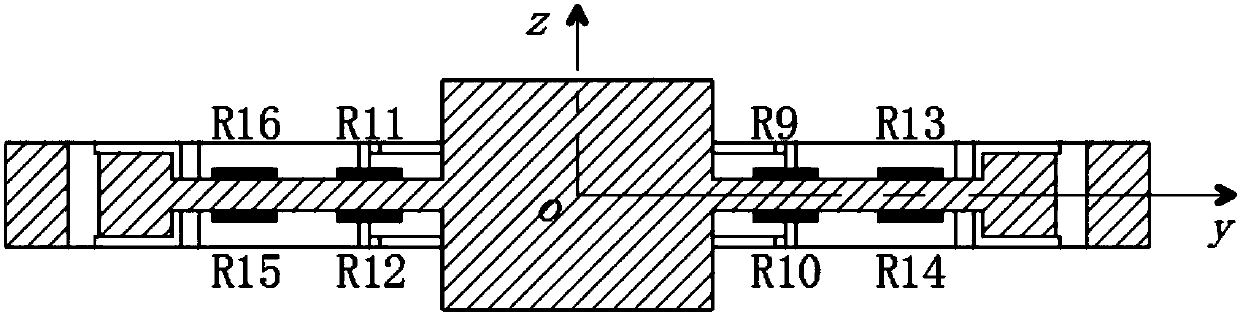

[0027] See figure 1 and figure 2 As shown, the embodiment of the present invention provides a multi-dimensional force / torque sensor 10, including: a hollow frame 100, a loading platform 110, a first elastic beam 120, a second elastic beam 130, a force transmission block 121 and a set of strain gauges. The first elastic beam 120 is connected to the hollow frame 100 , the second elastic beam 130 is connected to the first elastic beam 120 and supports the loading platform 110 on the hollow frame 100 . The force transmission block 121 divides the corresponding first elastic beam 120 into two parts perpendicular to each other in the width direction. The distance from the center of the multi-dimensional force / torque sensor varies. Each of the first elastic beam 120 and the second elastic beam 130 is attached with the set of strain gauges.

[0028] Now with figure 2 As an example, an xyz three-dimensional coordinate system is established with the geometric center of the loading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com