Cold air power spraying and coating method containing laser irradiation

A technology of cold air power spraying and laser irradiation, applied in the direction of heating inorganic powder coating, etc., can solve problems such as sticking throat, low radiation heating efficiency, phase change, etc., and achieve the effect of small thermal influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

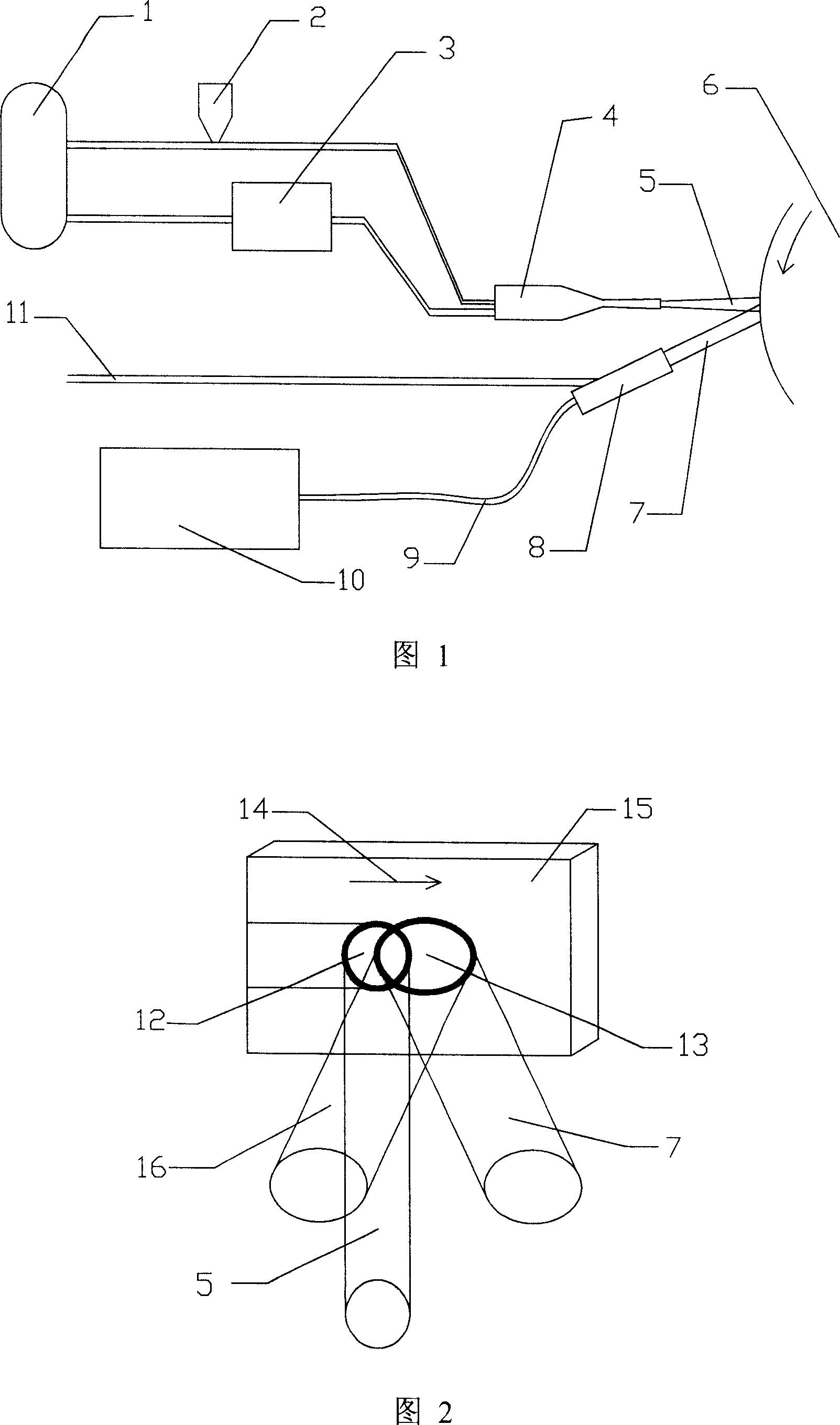

Method used

Image

Examples

Embodiment 1

[0033] Choose a pure copper substrate, and choose pure copper particles as the spraying material. In the absence of laser irradiation, the driving gas is an inert gas composed of nitrogen plus 8% helium, and the pressure of the driving gas is gradually increased from 0.5MPa. The measured critical velocity of copper particles on the pure copper plate is 498m / s. When the laser irradiation is increased, the angle between the laser and the particle beam is 30°, the temperature of the substrate in the laser spot area after laser irradiation is 500°C, and the measured critical velocity of the copper particles on the pure copper plate is 380m / s. The critical speed required for bonding was significantly reduced by 23.7%.

Embodiment 2

[0035] Choose pure aluminum substrate and choose pure aluminum particles as spraying material. In the absence of laser irradiation, the driving gas is an inert gas composed of nitrogen plus 8% helium, and the pressure of the driving gas is gradually increased from 0.5MPa. The measured critical velocity of aluminum particles on the pure aluminum plate is 650m / s. When the laser irradiation is increased, due to the strong reflection of aluminum, the angle between the laser and the particle beam is 45°, the temperature of the substrate in the laser spot area after laser irradiation is 350°C, and the measured copper particles adhere to the pure copper plate. The critical speed when connecting is 447m / s. The critical speed required for bonding was significantly reduced by 31.2%.

Embodiment 3

[0037] Choose pure 316L stainless steel substrate, choose 316L stainless steel particles as spraying material. In the absence of laser irradiation, the driving gas is an inert gas composed of nitrogen plus 8% helium, and the pressure of the driving gas is gradually increased from 0.5MPa. The measured critical velocity of 316L stainless steel particles on the 316L stainless steel plate is 710m / s. When the laser irradiation is increased, the angle between the laser and the particle beam is 25°, the temperature of the substrate in the laser spot area after laser irradiation is 550°C, and the measured critical velocity of the 316L stainless steel particles on the 316L stainless steel plate is 578m / s. The critical speed required for bonding was reduced by 18.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com