Workpiece bonding system

A workpiece and bonding head technology, applied in electrical components, electrical solid devices, semiconductor devices, etc., can solve the problems of larger equipment size, increased equipment cost, low flexibility of preprocessing configuration, etc., to reduce transfer time, improve Production efficiency, the effect of saving production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to make the technical problems, technical solutions, and advantages to be solved by the embodiments of the present invention clearer, a detailed description will be given below with reference to the drawings and specific embodiments.

[0069] In view of the relatively low efficiency of the chip bonding equipment in the prior art, the embodiments of the present invention provide a workpiece bonding system, which uses a transfer method for the workpiece, and can also preprocess the workpiece during the transfer process. Reduce the time consumption of workpiece transfer and pretreatment, and improve the efficiency of workpiece bonding.

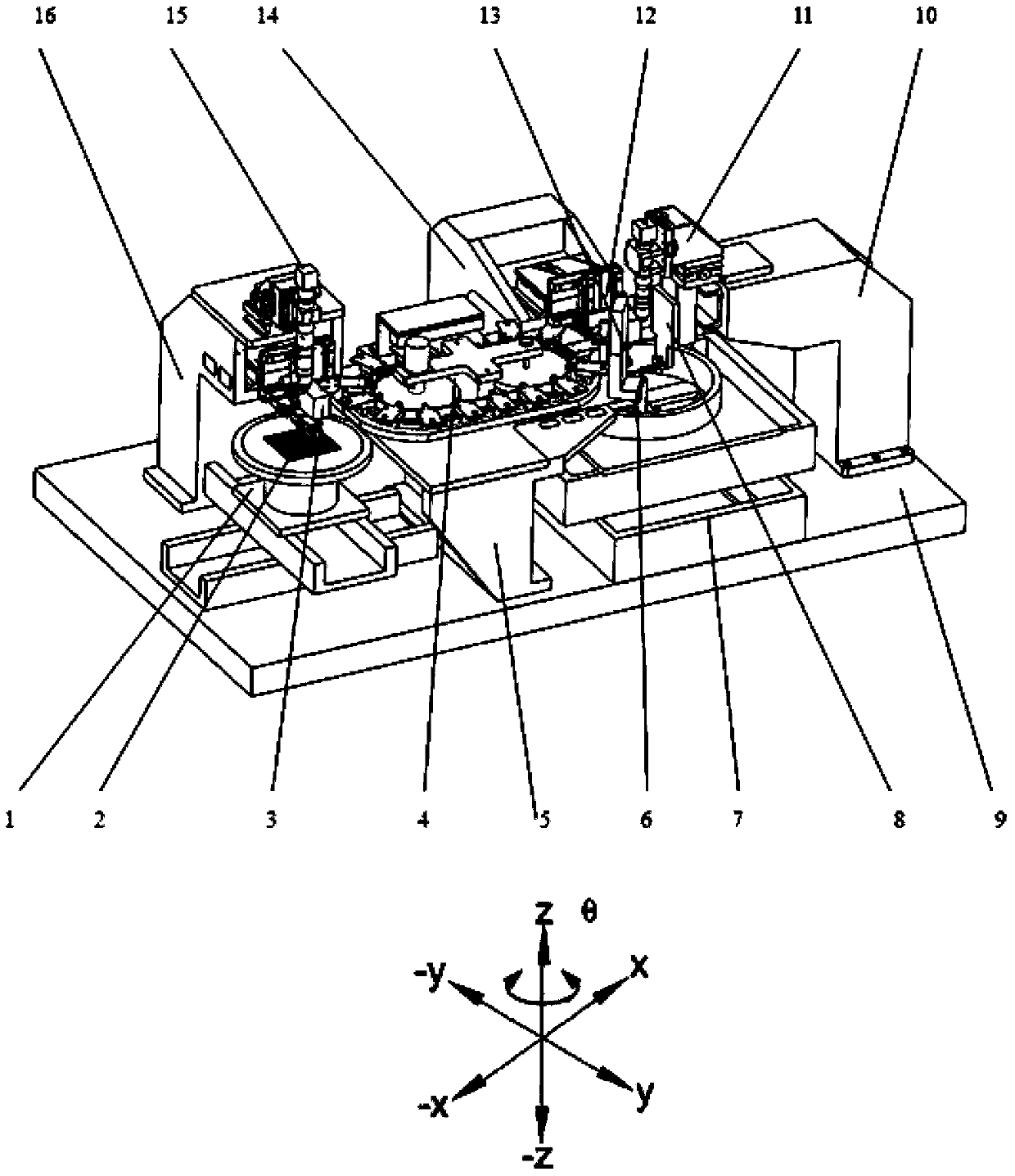

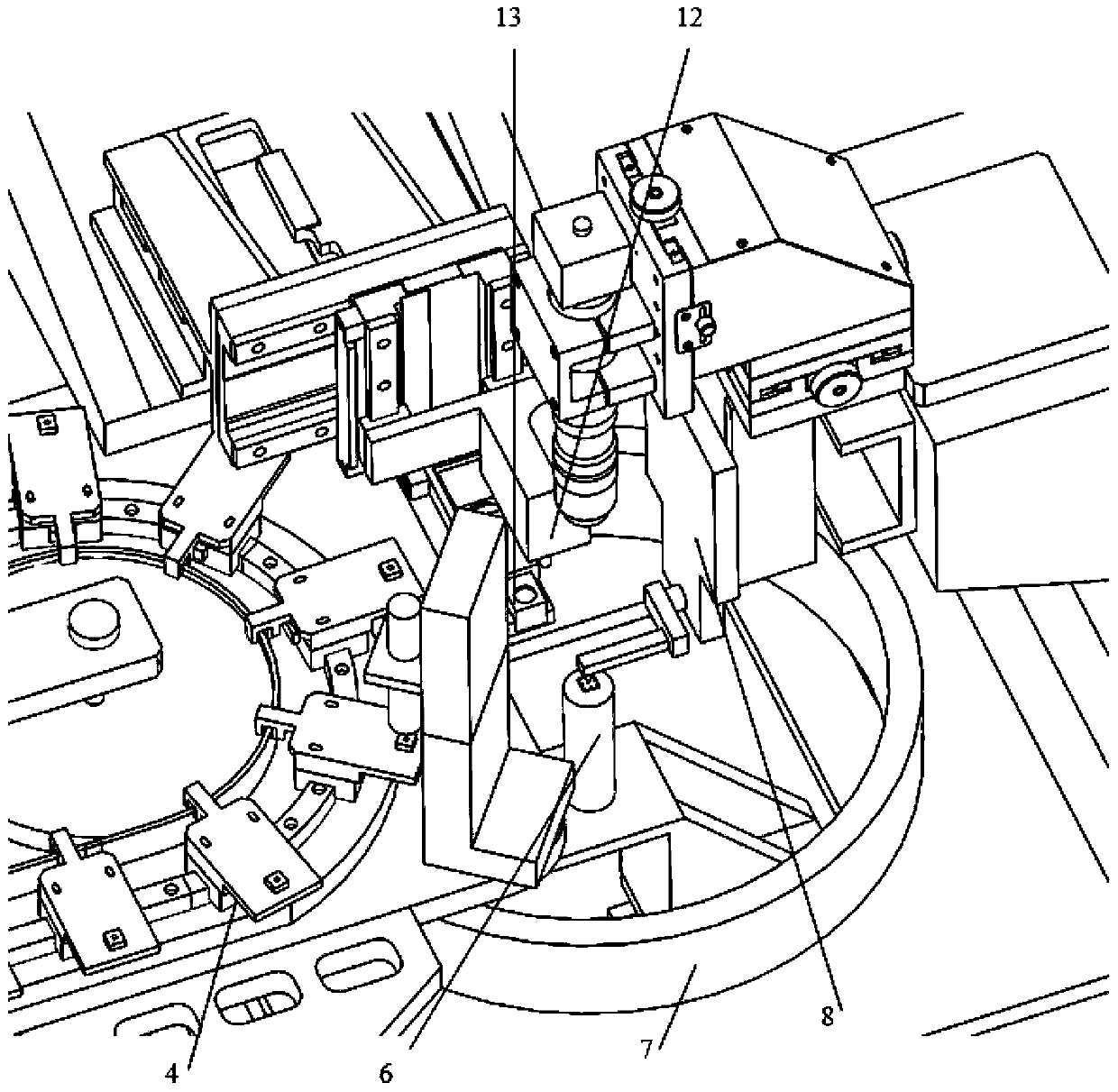

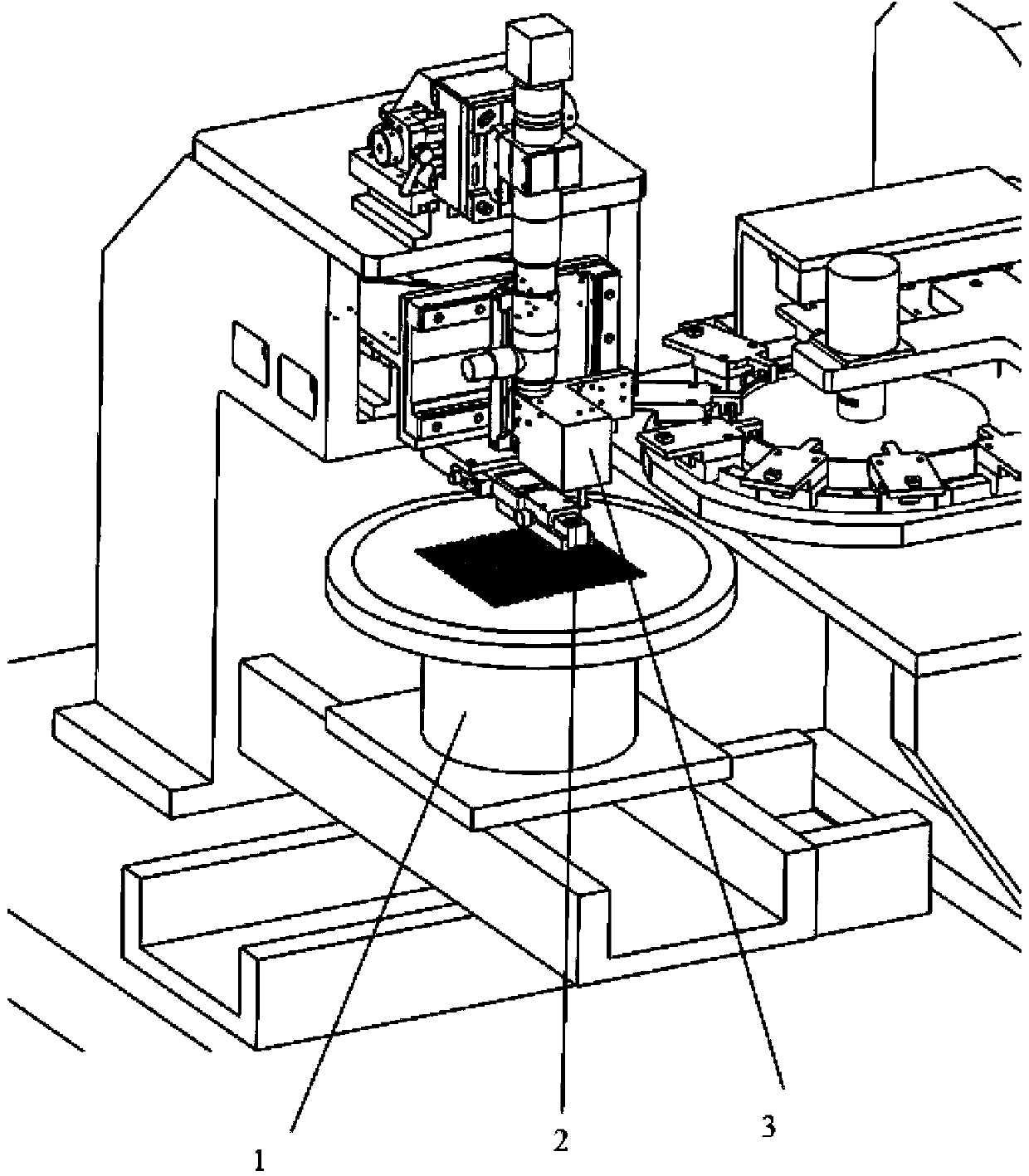

[0070] The embodiment of the present invention provides a workpiece bonding system, which includes a platen, a workpiece providing device provided on the platen, a workpiece conveying device, and a workpiece processing device, wherein,

[0071] The platen is used to support and fix each component of the entire workpiece bonding system;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com