Multi-layer mixed synchronization bonding structure and method for three-dimensional packaging

A multi-layer hybrid and three-dimensional packaging technology, which is applied to semiconductor/solid-state device components, welding equipment, manufacturing tools, etc., can solve problems affecting production efficiency and product reliability, long bonding time, high bonding temperature, etc., to achieve Increase bonding strength and reliability, save time and cost, and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

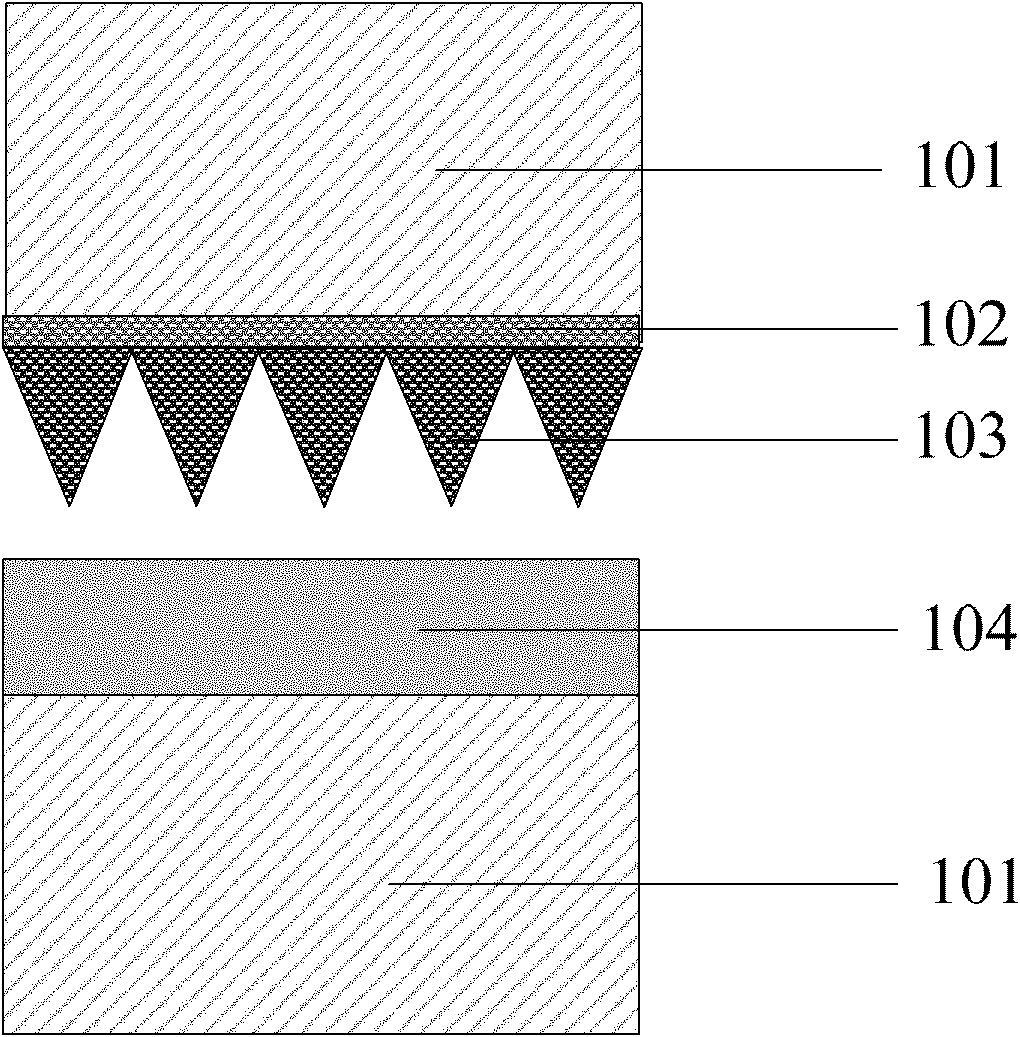

[0033] figure 1It is a structural schematic diagram of the surface of the pad after upper and lower bonding in the embodiment of the present invention. Taking the silicon base plate as an example, metal through holes are formed on the silicon base plate of each layer to form interconnections, and the upper and lower metal interconnection structures are soldered on the surface. A special bonding structure is formed on the disk such as figure 1 As shown, it can be seen from the figure that there is a layer of metal pad 101 on the upper and lower substrates, preferably metal copper, and a hard metal layer 102 can be formed on the upper pad as required, which can be metal chromium, titanium, nickel, etc. The pad is in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com