Built-in conical throttling gear

A throttling device, built-in technology, applied in the direction of detecting fluid flow by measuring differential pressure, volume/mass flow generated by mechanical effects, etc., can solve problems such as increased maintenance intensity, poor stability of measured flow, and complicated influence. Achieve the effects of improved pressure taking stability, improved service life and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

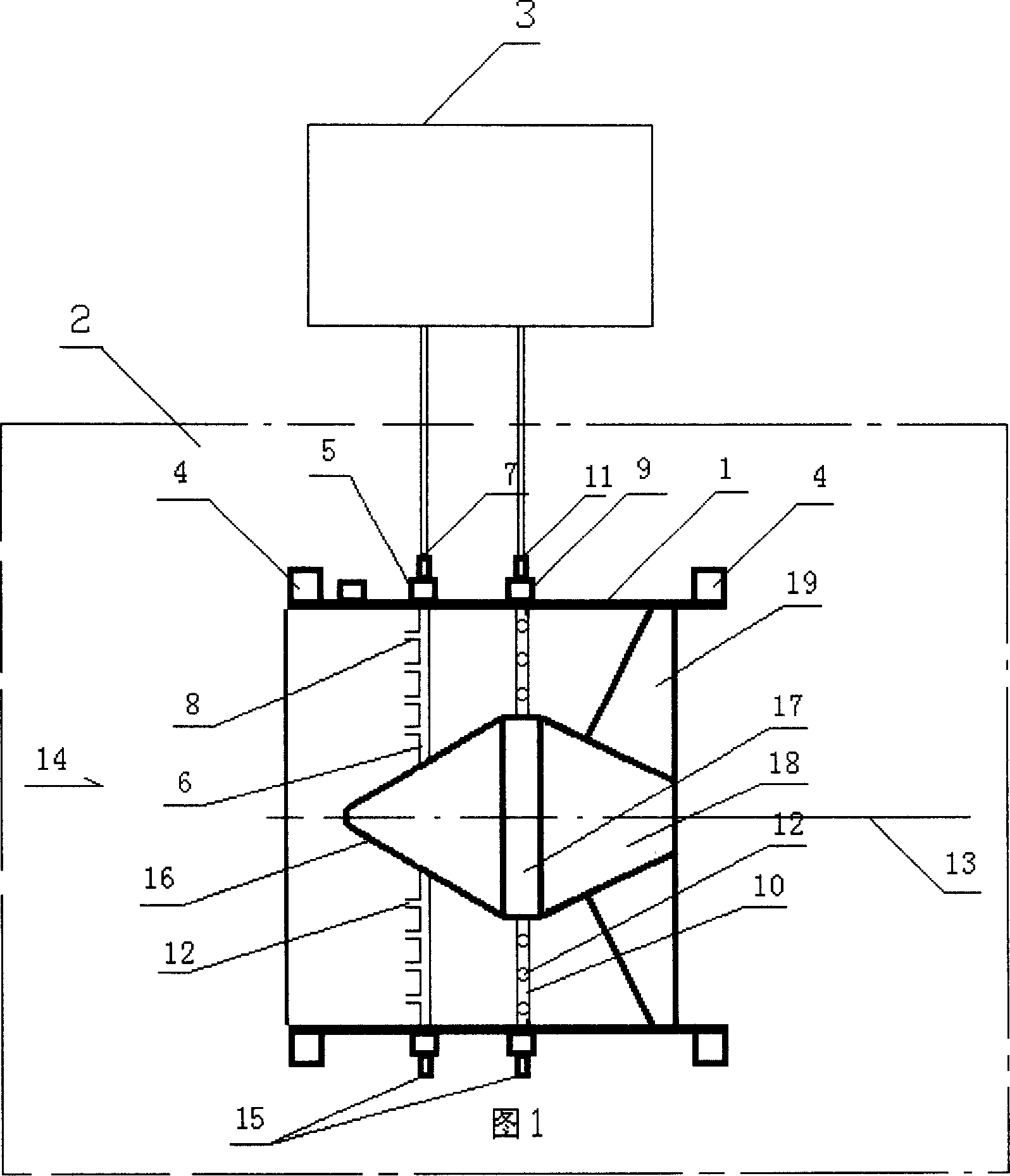

[0027] As shown in Fig. 1, a kind of structure of sensing device 2 is provided, and sensing device 2 comprises pipe body 1, the diversion cone in pipe body 1, and wherein diversion cone is divided into front cone 16, straight The pipe 17, the rear cone 18 and the empennage 19 form an integral body; the diversion cone is connected with the pipe body 1 through the empennage 19; The pipe body 1 has a hollow front confluence pipe 5 around the outer layer, and a front pressure measurement pipe 6 extending from the front confluence pipe 5 to the inner edge of the pipe body 1 to the front cone 16. The front pressure measurement pipe 6 is at 2-8 The roots are evenly distributed at an angle to each other. There are 1-4 front pressure measuring heads 8 on each front pressure measuring tube 6, the front pressure measuring heads 8 are arranged in parallel with each other and the fluid direction 14 flows to the opposite direction, and the front pressure measuring head 8 ends have openings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com