Optical system internal chamber precision gas control method and device thereof

An optical system and internal chamber technology, applied in the direction of fluid pressure control without auxiliary power, etc., can solve the problems of inability to meet the requirements, poor adaptability of the optical system, etc., to suppress secondary pollution, simple structure, and good pressure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

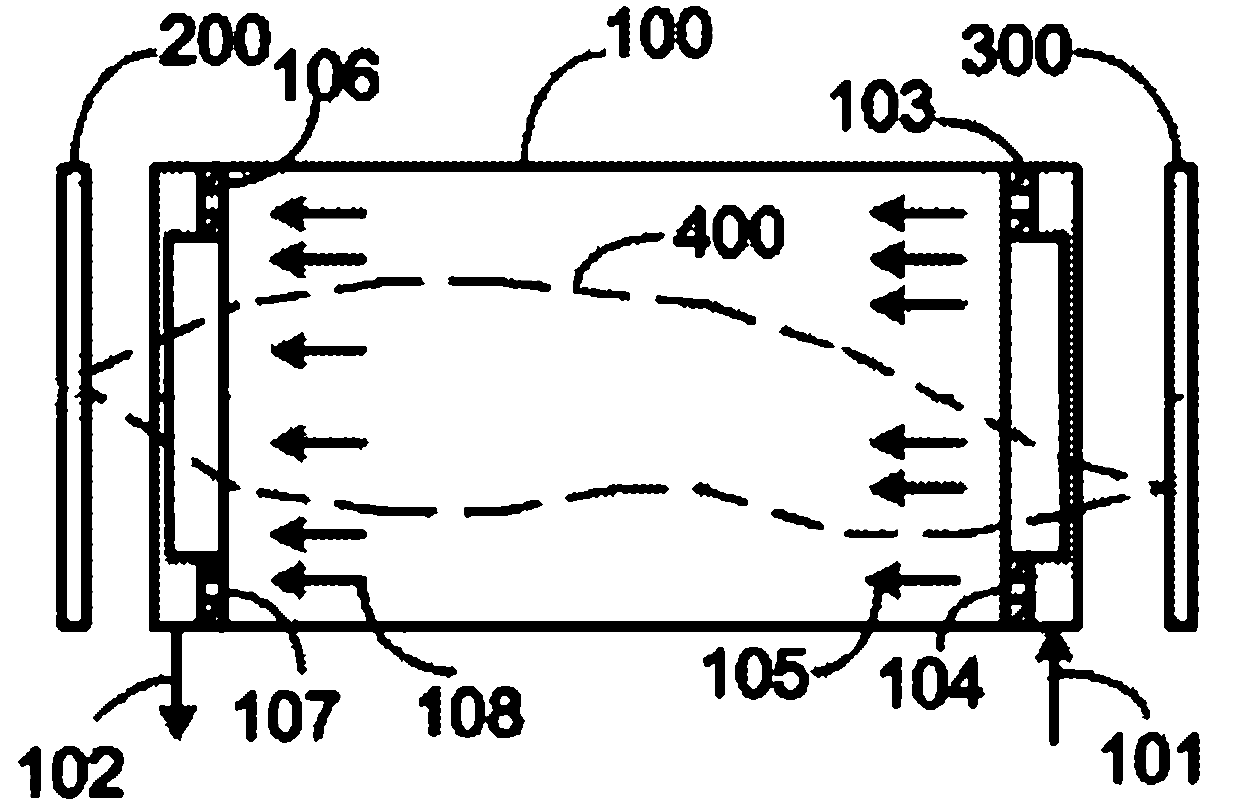

[0039] see figure 1 , figure 1 Shown is a schematic diagram of the structure of the imaging device and its internal chamber of the optical system. The imaging device includes an optical system 100 , and an object plane 200 and an image plane 300 respectively disposed on both sides of the optical system 100 . The light path 400 enters the optical system 100 after passing through the object plane 200 , and is projected onto the image plane 300 after being processed inside the optical system 100 . The inner chamber of the optical system 100 is filled with the cleaning gas, and the uniform flow of the gas can enhance the cleaning effect. In order to realize gas flow, an air inlet 101 and an air outlet 102 are respectively provided at both ends of the optical system 100 . In order to achieve the uniformity of the input air flow, an air intake flow equalization component 103 is provided in the inner chamber on the side of the air inlet 101 of the optical system 100 . The intak...

no. 2 approach

[0070] The difference between the second embodiment and the first embodiment is that the inner chamber of the optical system involved in the second embodiment requires absolute pressure control, and the first gas control circuit designed by the above method needs to be adjusted accordingly. The same numbers are used for the same parts of the second embodiment and the first embodiment, and the same parts will not be repeated.

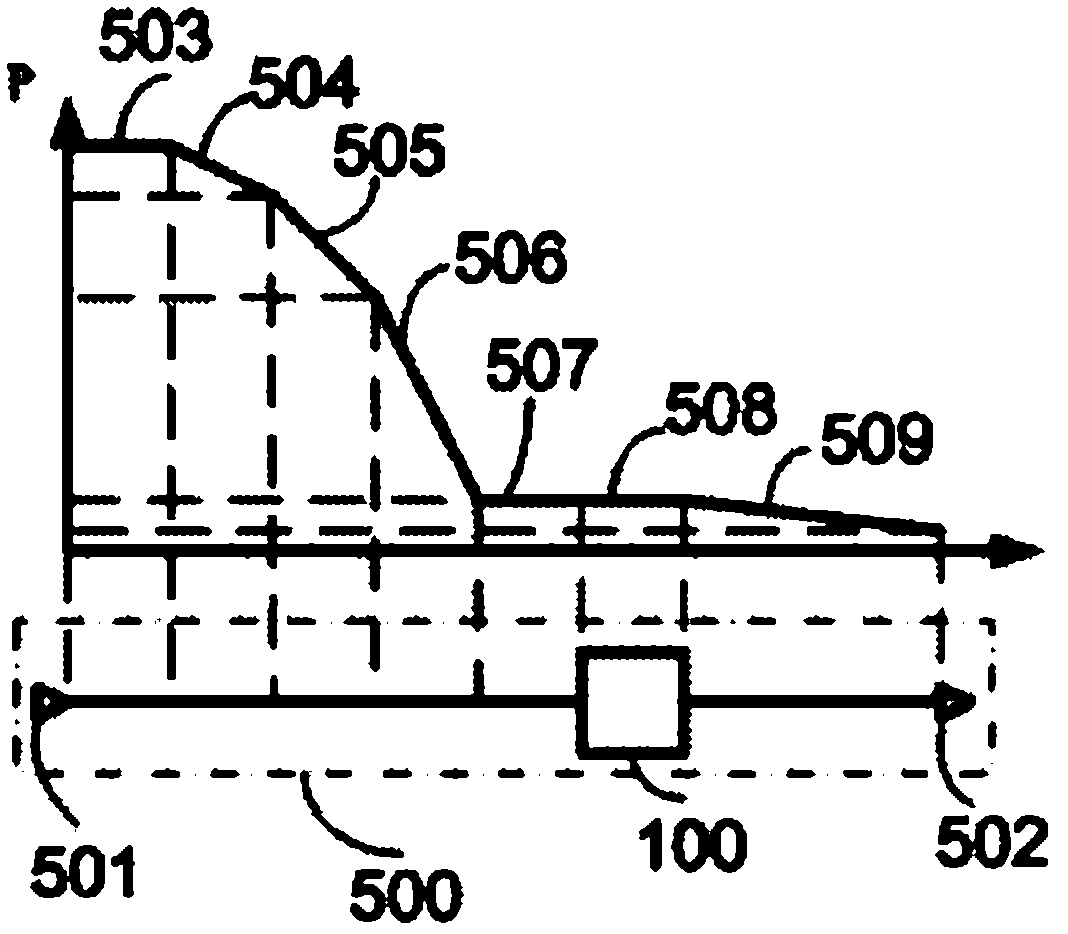

[0071] see Figure 6 , Figure 6 Shown is a schematic diagram of the structure of the precise gas control device in the inner chamber of the optical system with the function of absolute pressure control. The precision gas control device in the inner chamber of the optical system with absolute pressure control function includes an optical system 100, a second gas control circuit 550 and a control system. The second gas control circuit 550 includes two parts: a gas supply circuit and an exhaust circuit. The gas supply circuit includes control devices an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com