Converter tapping monitoring control system based on thermal image processing

An image processing, monitoring and control technology, applied in the manufacture of converters, etc., can solve the problems of difficult to guarantee recognition rate, unadjustable resolution, difficult reconstruction optimization, etc., to achieve timely and accurate alarm, increase system cohesion, and system parameters Online adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In conjunction with the accompanying drawings, the present invention will be described in detail below.

[0034] 1. System function framework and module composition

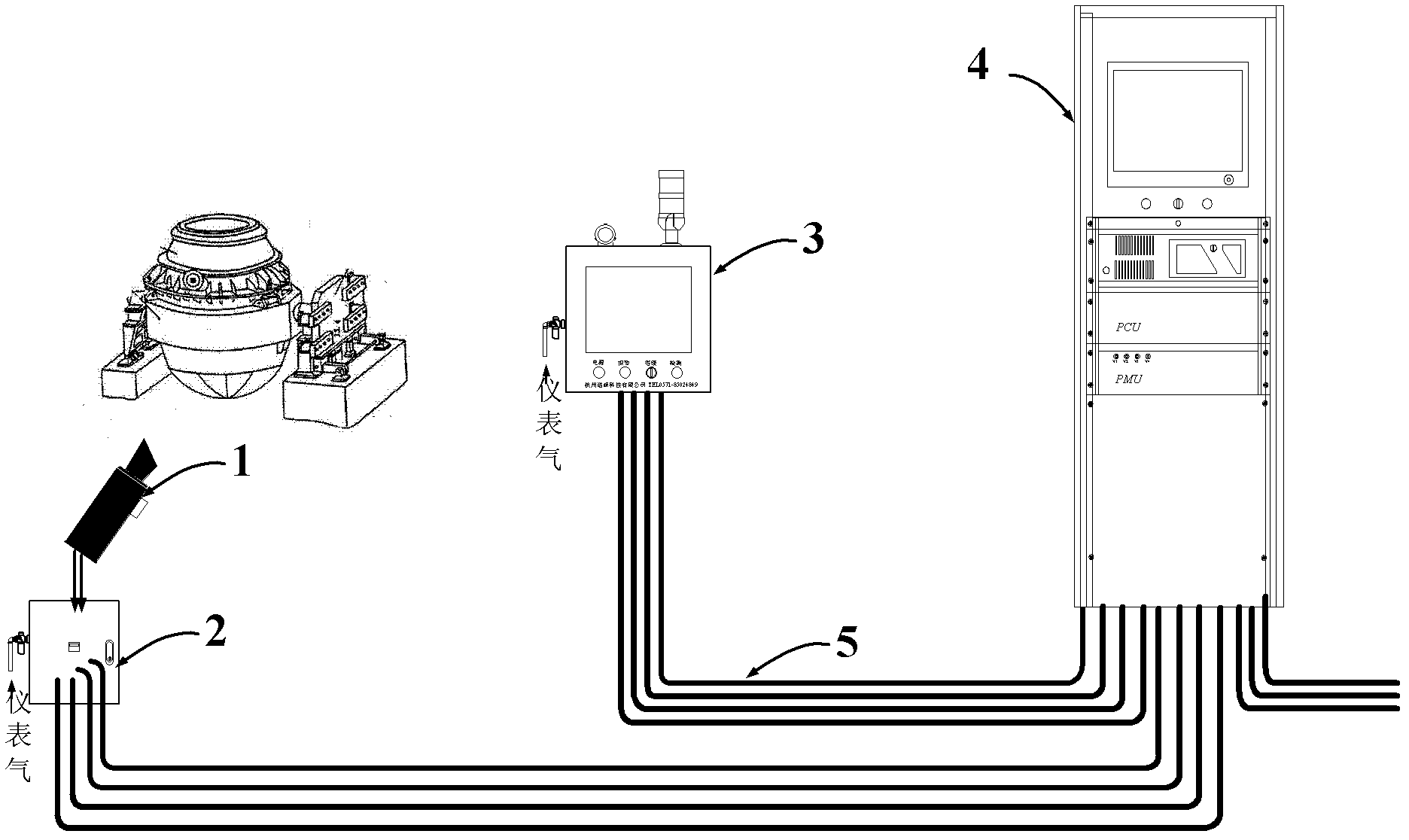

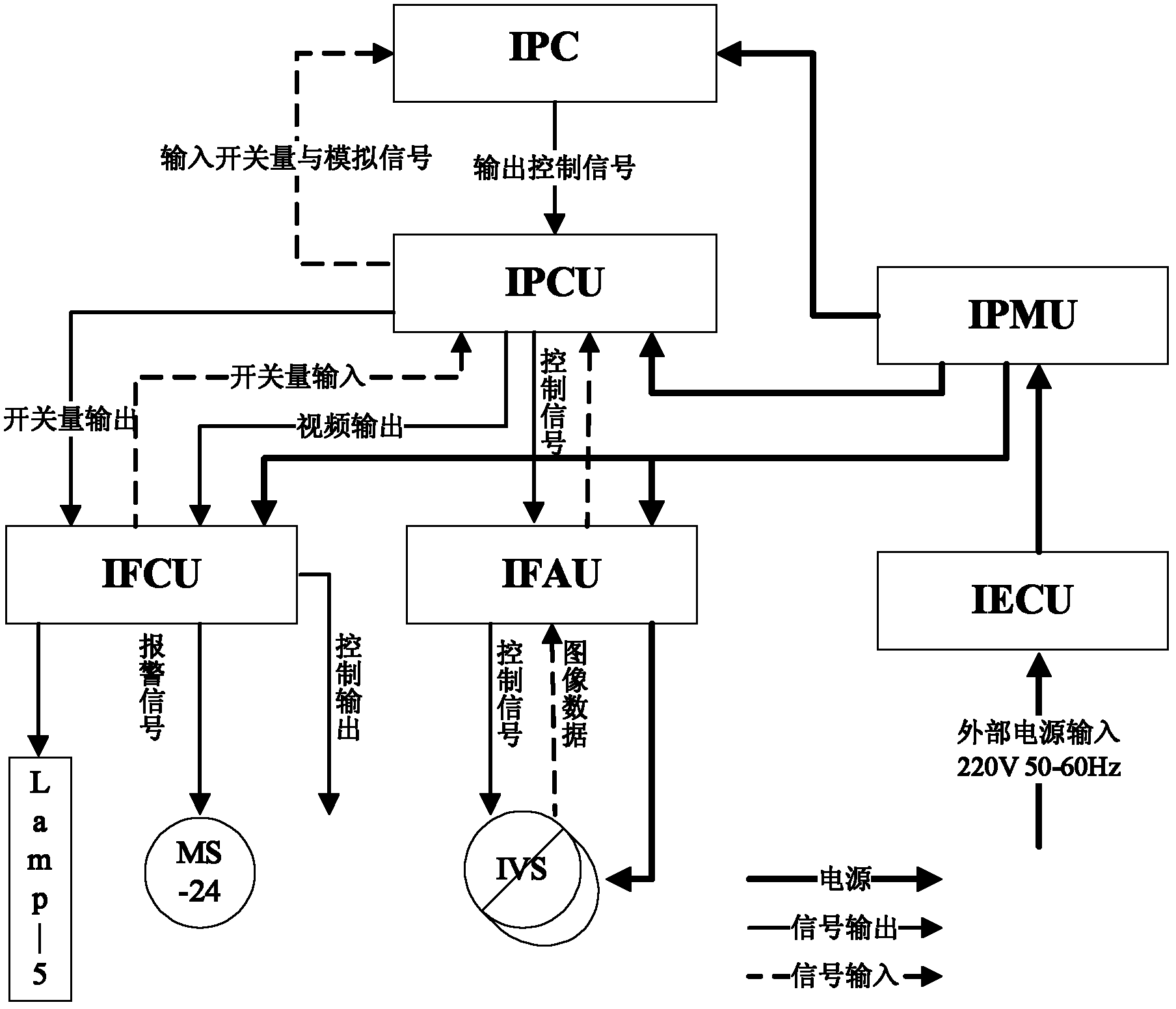

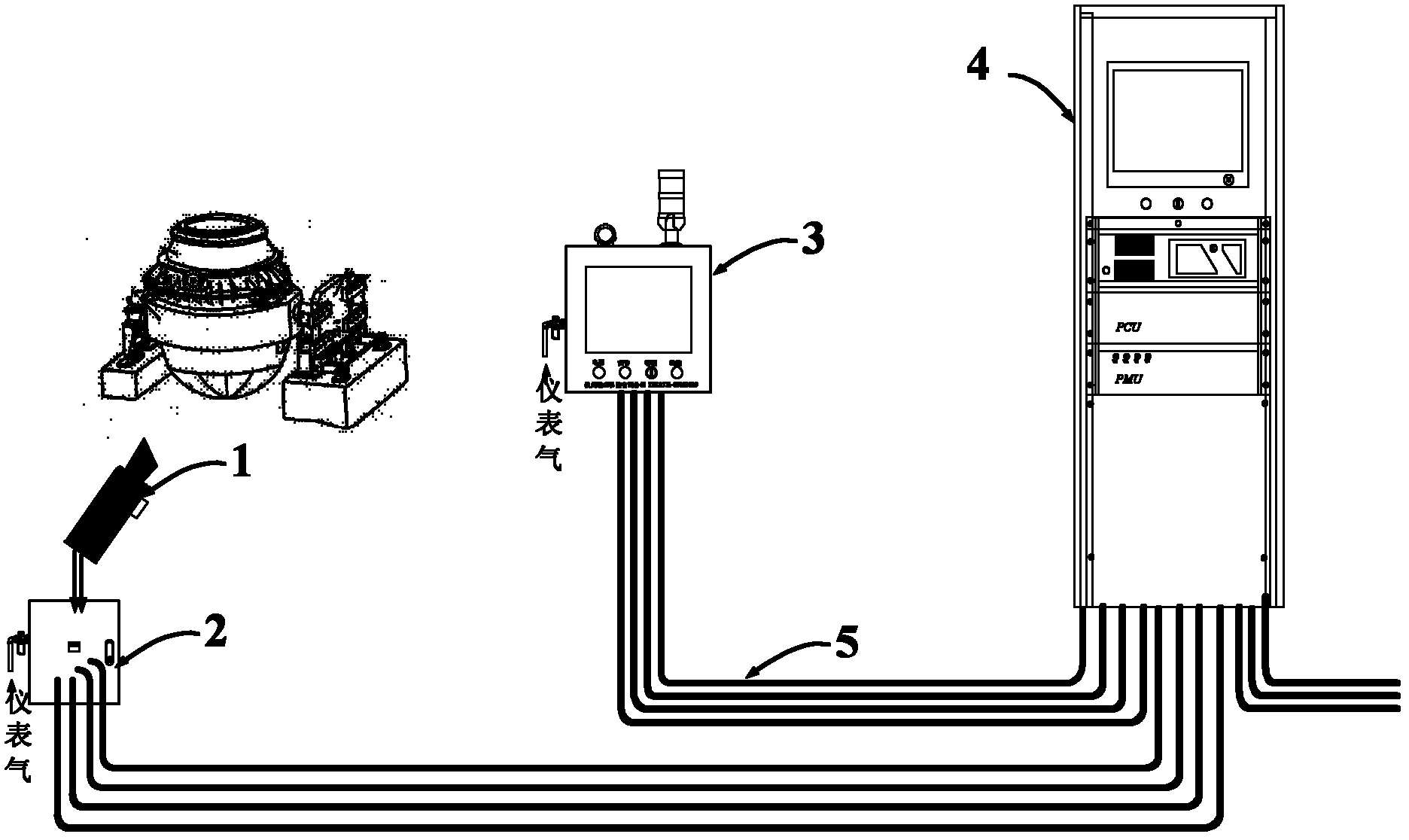

[0035] The overall technical scheme of the present invention is: using a far-infrared thermal imager to collect the thermal image signal of the steel flow when the converter is tapping out, according to the difference in thermal radiation rate of molten steel and steel slag contained in the steel flow in a specific far-infrared band range, combined with discrete wavelet Transform (Discrete Wavelet Transfer, DWT) algorithm to identify the state of steel flow online, and then issue relevant control instructions to drive the on-site execution device to complete real-time monitoring and automatic control of converter tapping, and finally achieve the goal of reducing steel slag in the ladle content, but also to increase the yield of molten steel and reduce the labor intensity of workers.

[0036] The functiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com