Parallel liquid phase chromatographic pump

A liquid chromatography and parallel technology, which is applied in the direction of pumps, piston pumps, liquid displacement machinery, etc., can solve the problems of poor liquid pressure stability, difficult cam design, complex cam structure, etc., to achieve convenient cam processing and reduce industrial costs. Design Difficulty, Cam Curve Simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be noted that the embodiments described here are for illustration only, and are not intended to limit the present invention.

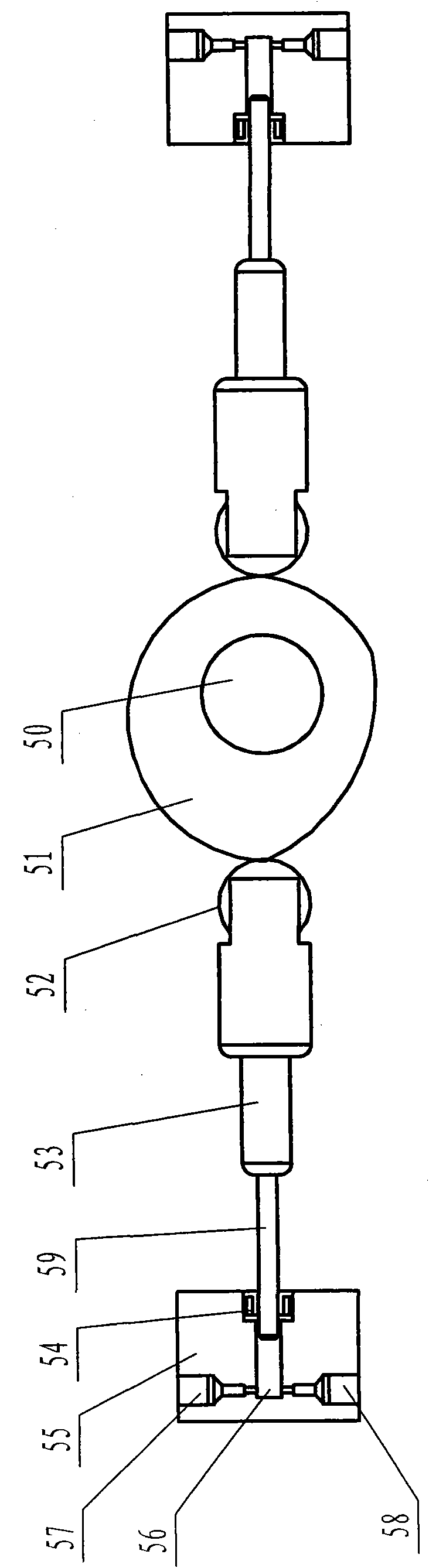

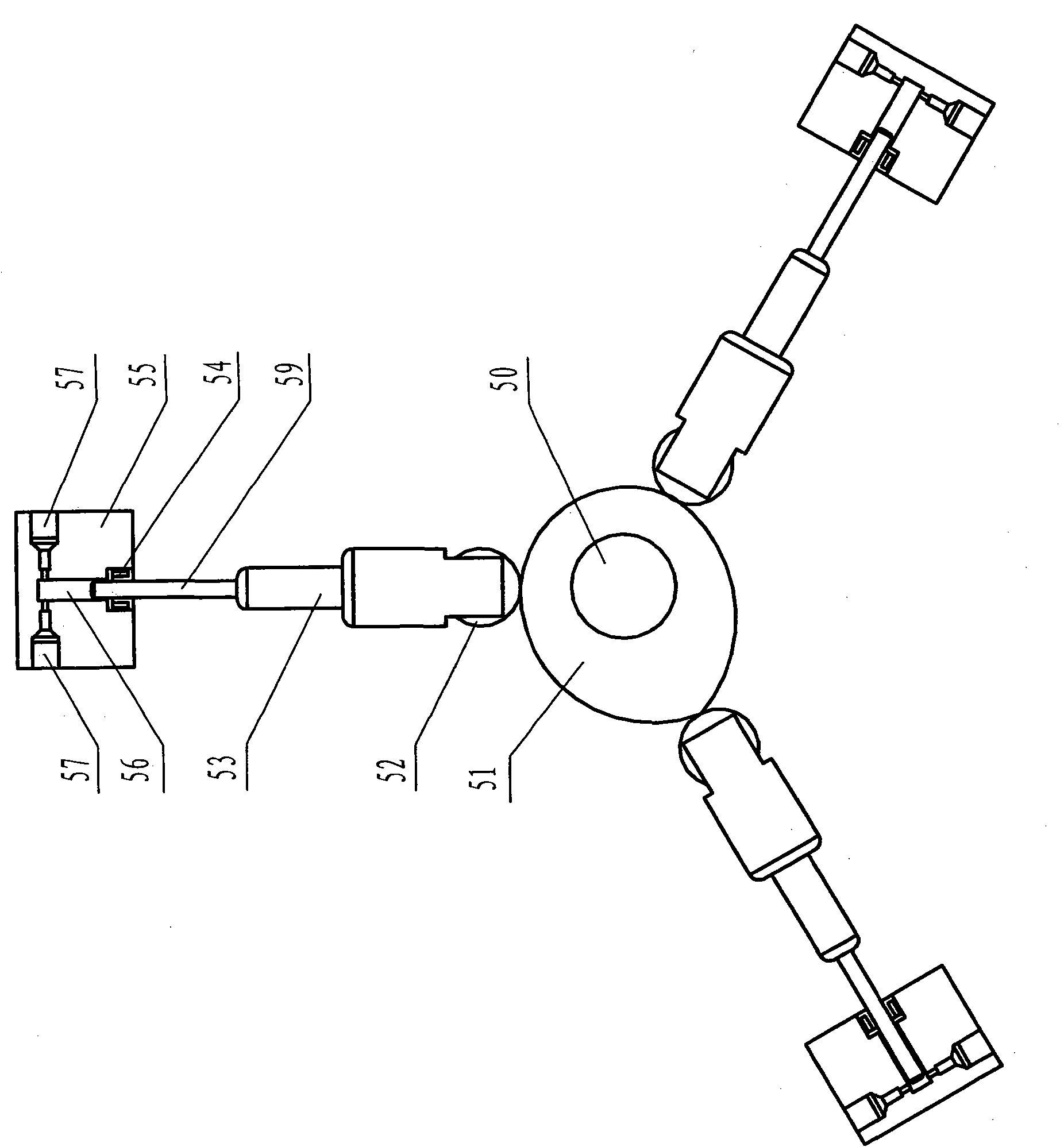

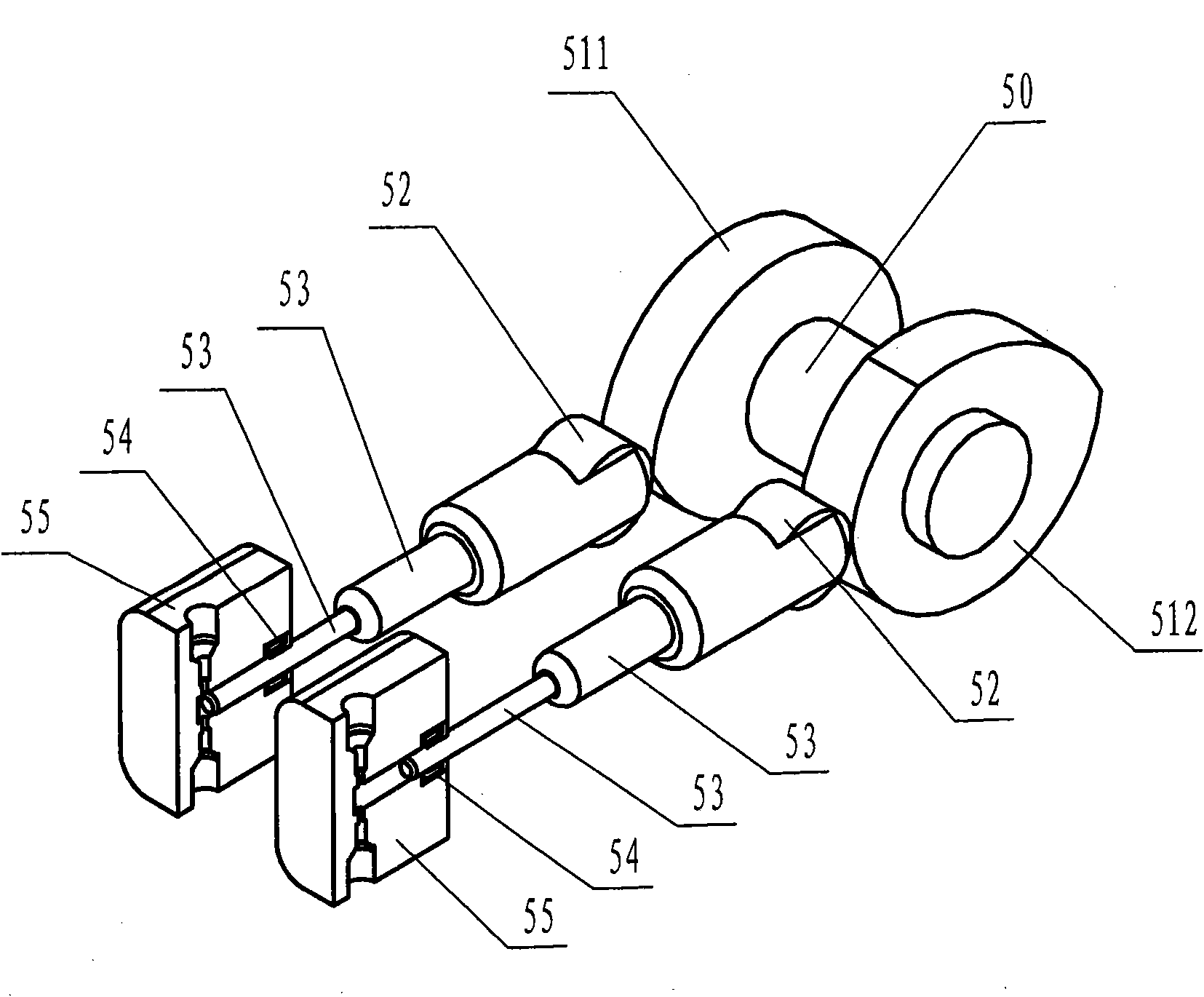

[0045] Such as Figure 4 , Figure 8 As shown, the cam 61 in the parallel liquid chromatography pump of the present invention is an end face cam, and its cam curve is arranged on the other end face opposite to the end face having the camshaft 60 . The cam curve includes a rising curve that can convert the rotational motion of the cam 61 into a uniform linear motion of the plunger 69, a falling curve that returns the plunger 69 to its original position, and a transition curve connecting the rising curve and the falling curve. A smooth transition line (not shown in the figure) is provided at the junction of the two curves. In order to improve the stability of the liquid pressure, trimming curves (not shown in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com