Series-parallel connection liquid chromatogram pump

A liquid chromatography and parallel technology, applied in the field of series-parallel liquid chromatography pumps, can solve the problems of poor liquid pressure stability, difficult cam design, complex cam structure, etc., and achieves easy trimming, reduced industrial design difficulty, and simple cam curve. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Definition of terms involved in the present invention:

[0045] The "series" in the series-parallel liquid chromatography pump refers to the simultaneous operation of multiple reciprocating liquid chromatographic pumps, which helps increase the pump displacement; the "parallel" refers to the sequential working of multiple reciprocating liquid chromatographic pumps. To ensure that the pump can continuously supply liquid to the system.

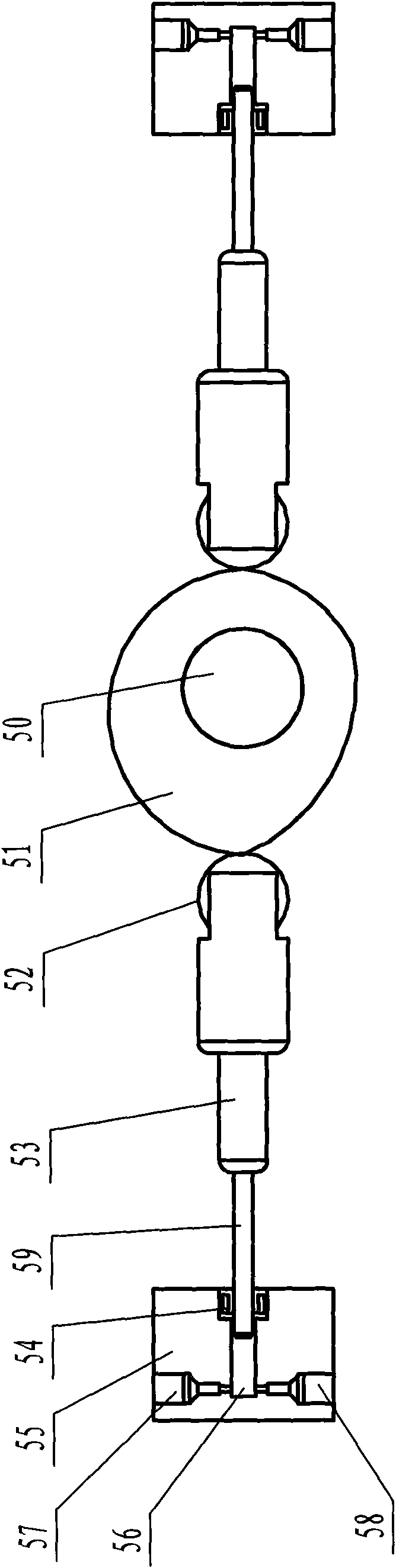

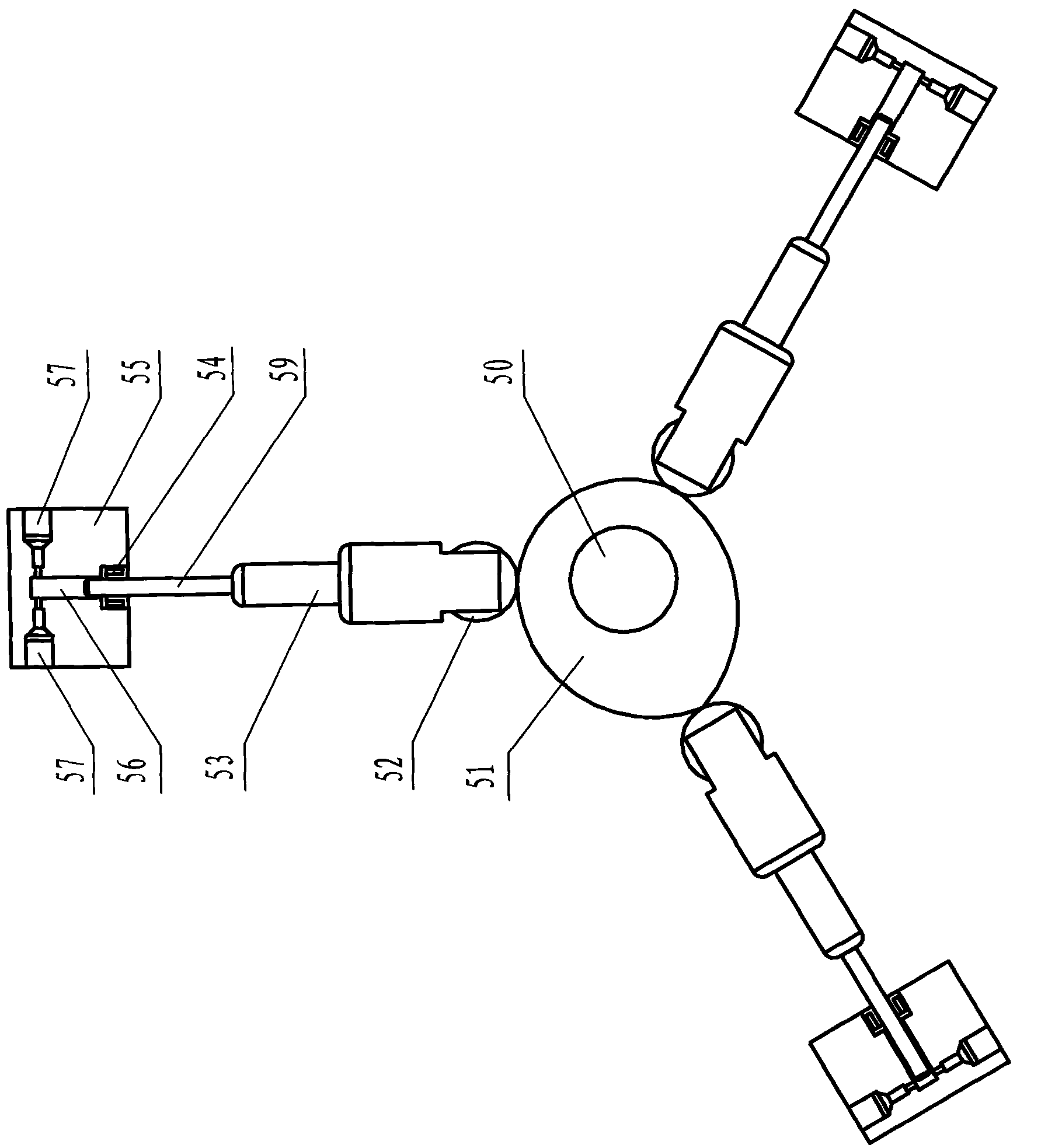

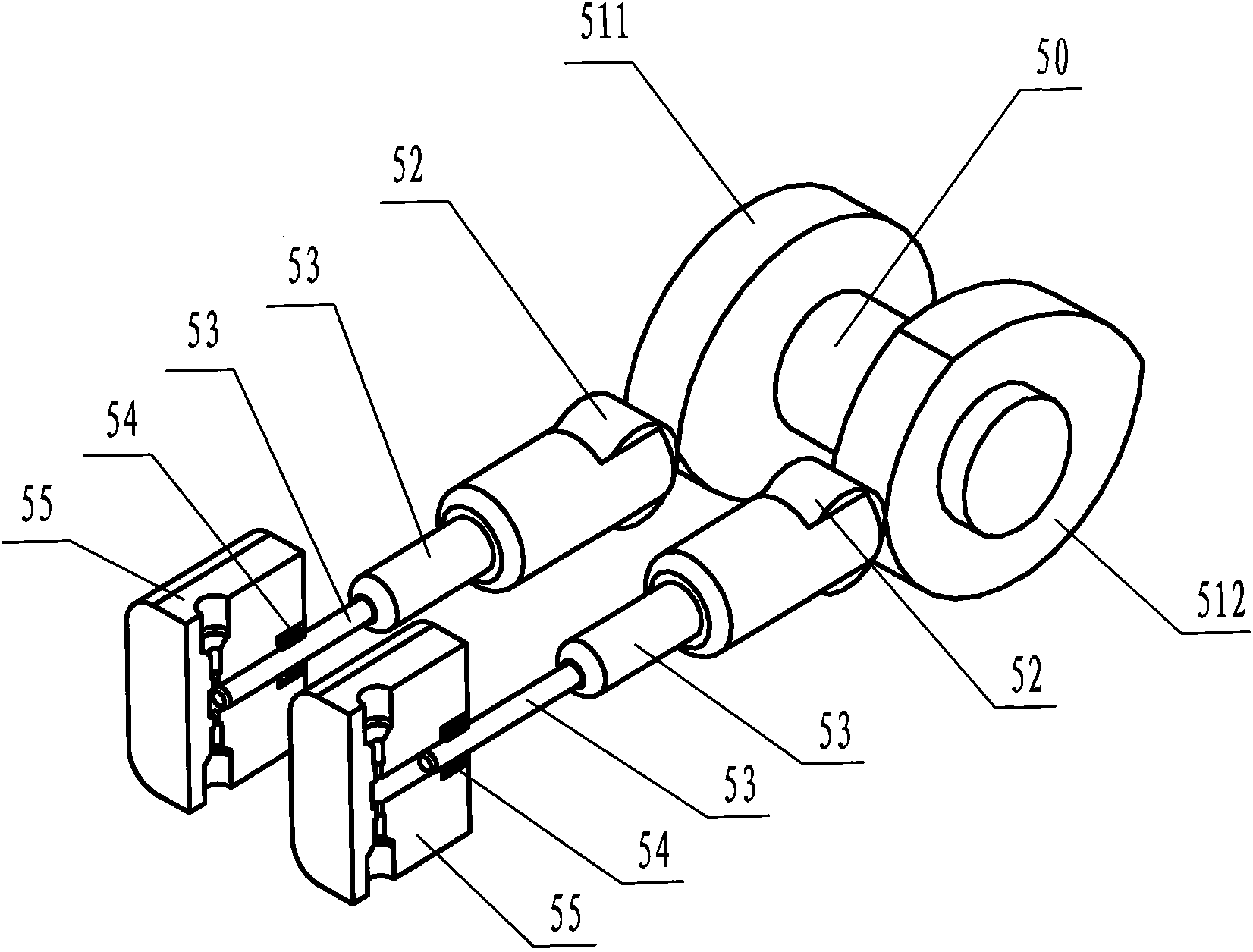

[0046] Such as Figure 4 , Figure 8 As shown, the cam 61 in the series-parallel liquid chromatography pump of the present invention is an end face cam, and its cam curve is set on the other end face opposite to the end face with the cam shaft 60. Each curve includes at least two curve units, and each curve unit includes an ascending curve that can convert the rotational movement of the cam 61 into a uniform linear movement of the plunger 69, a descending curve that returns the plunger 69 to its original position, and a connecting ascending c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com