Charge-air cooler for motor vehicles

A supercharged air cooling, automotive technology, applied in the direction of heat exchanger shell, indirect heat exchanger, machine/engine, etc., can solve the problem of high cost, achieve the effect of wide application range and reduce manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

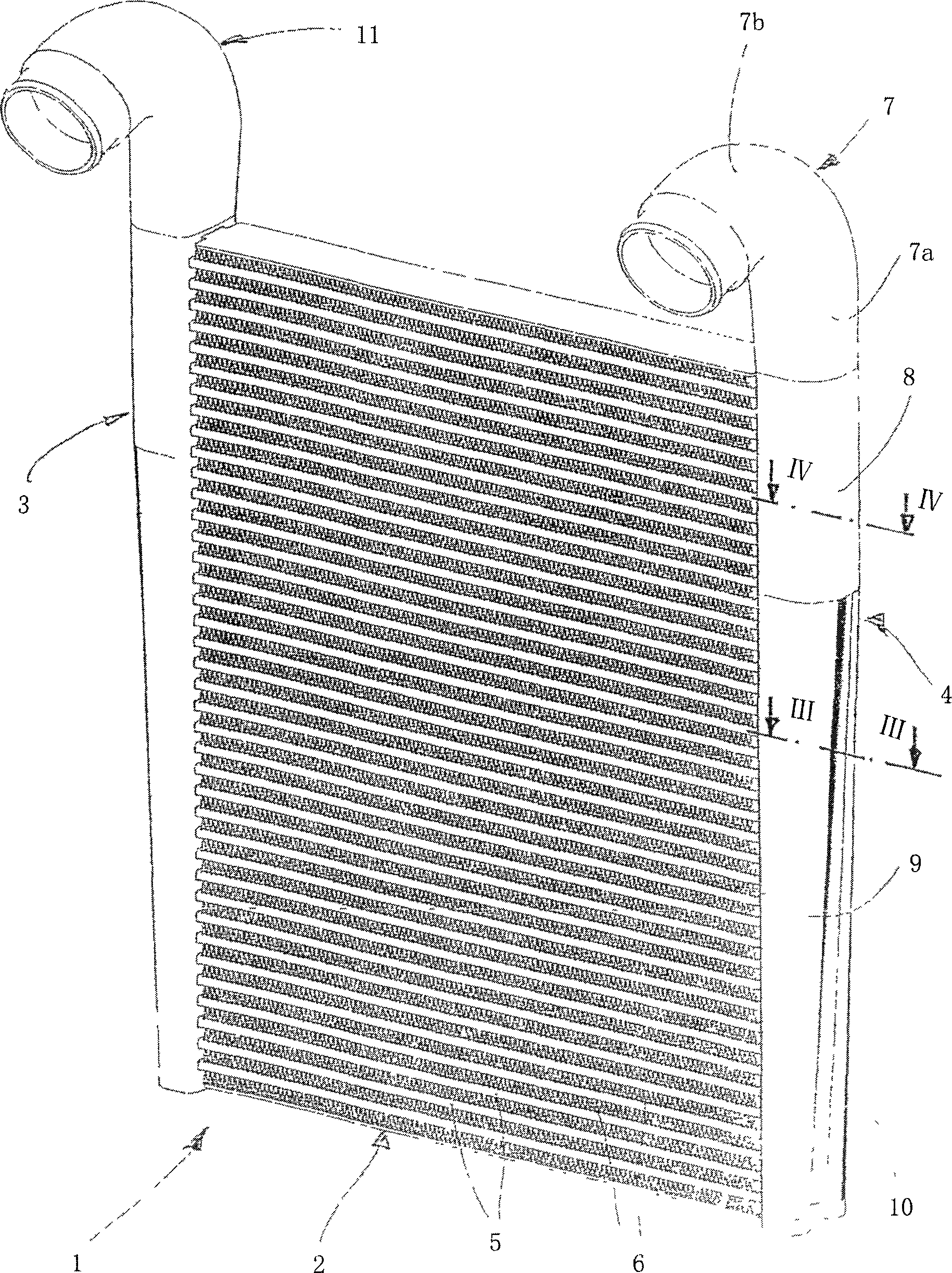

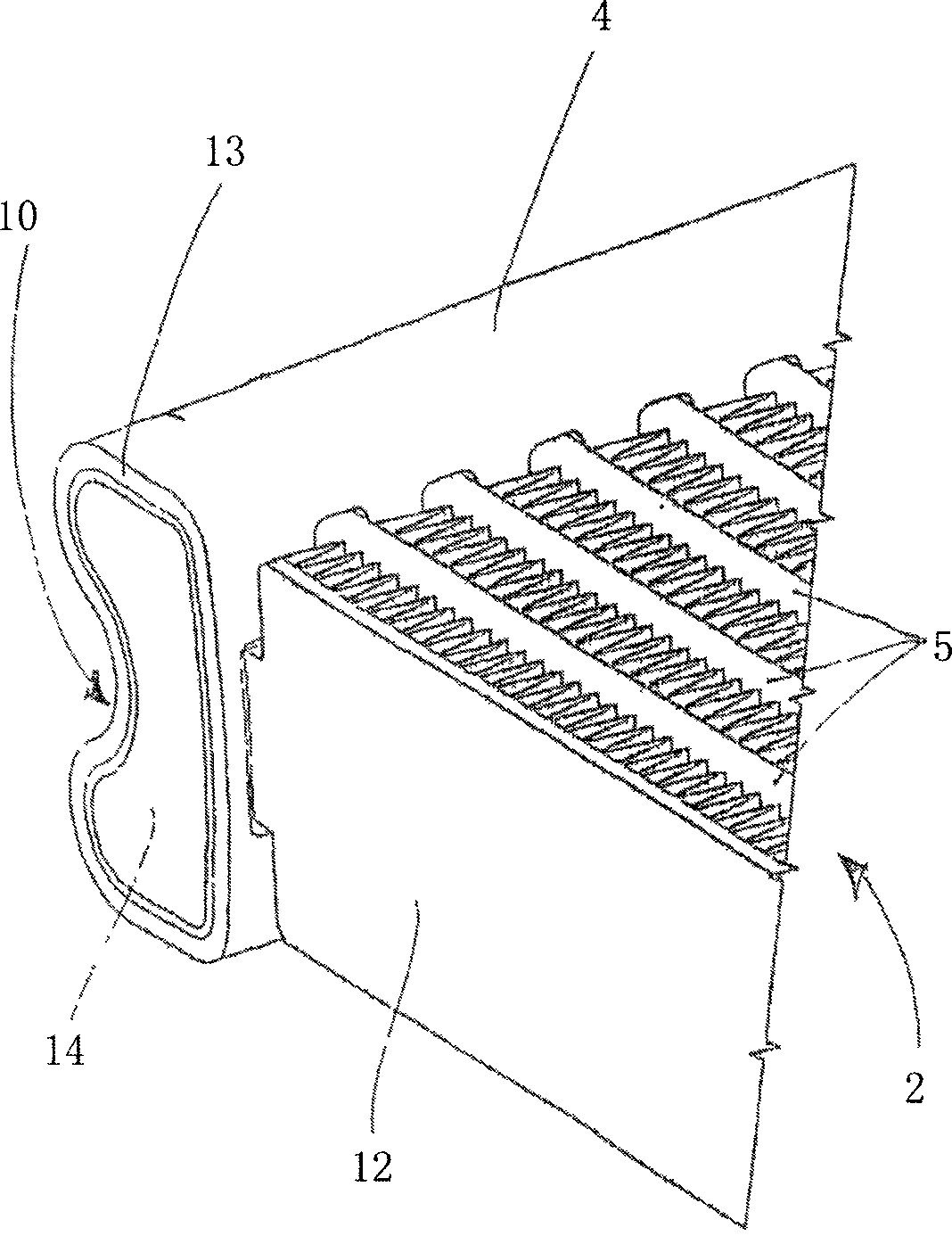

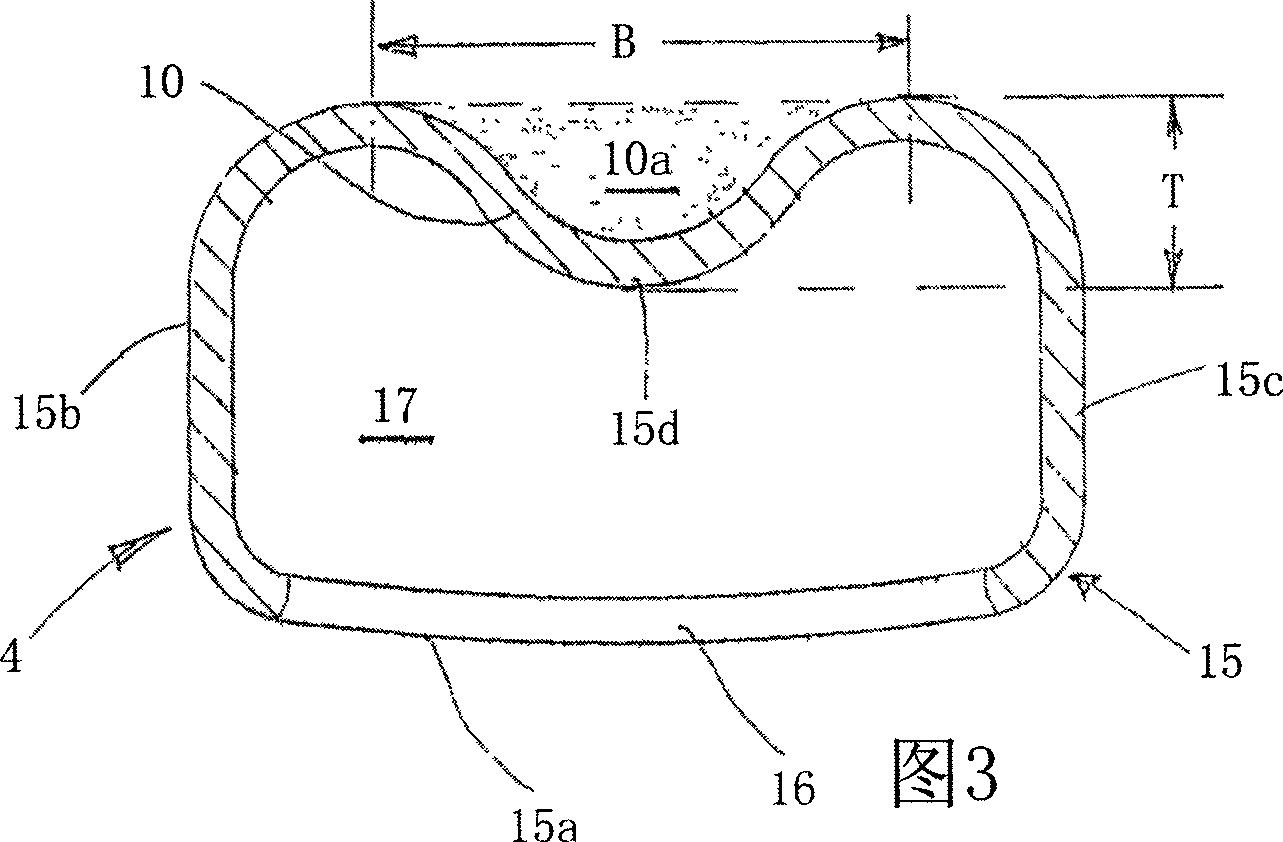

[0021] figure 1 In the figure is a charge air cooler 1 according to the invention, which consists of a heat exchanger core 2 and air boxes 3 , 4 arranged on both sides. The heat exchanger core 2 consists of flat tubes 5 and corrugated fins arranged between the flat tubes and through which ambient air flows. The tubes 5 lead into the air boxes 3 , 4 and are brazed together with them and the corrugated fins 6 . All parts such as tubes 5, wave fins 6 and air boxes 3, 4 are made of aluminum alloy. Each air box is a single whole and is divided into three sections (take air box 4 as an example), namely connecting pipe 7, cylindrical part 8 (non-cylindrical) and tapered or gradually flattened, with a The portion 9 of the longitudinal groove 10 extends in the longitudinal direction of the air box 4 . The connecting pipe 7 has a straight portion 7a completely centered and connected to the straight air box portion 8, and a bent portion 7b bent by about 90° to 120°. The air box 3 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com