Patents

Literature

46results about How to "Pressing to achieve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

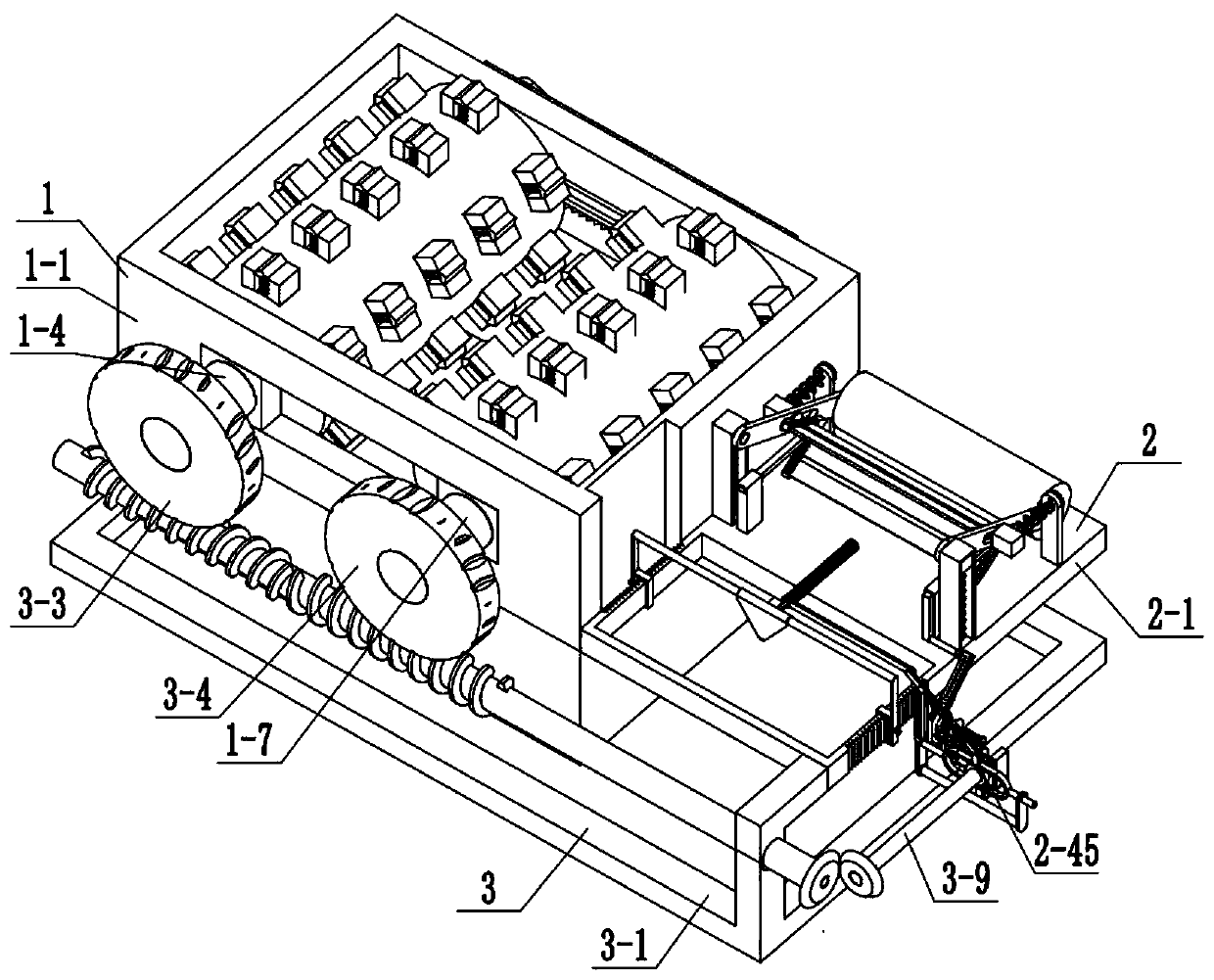

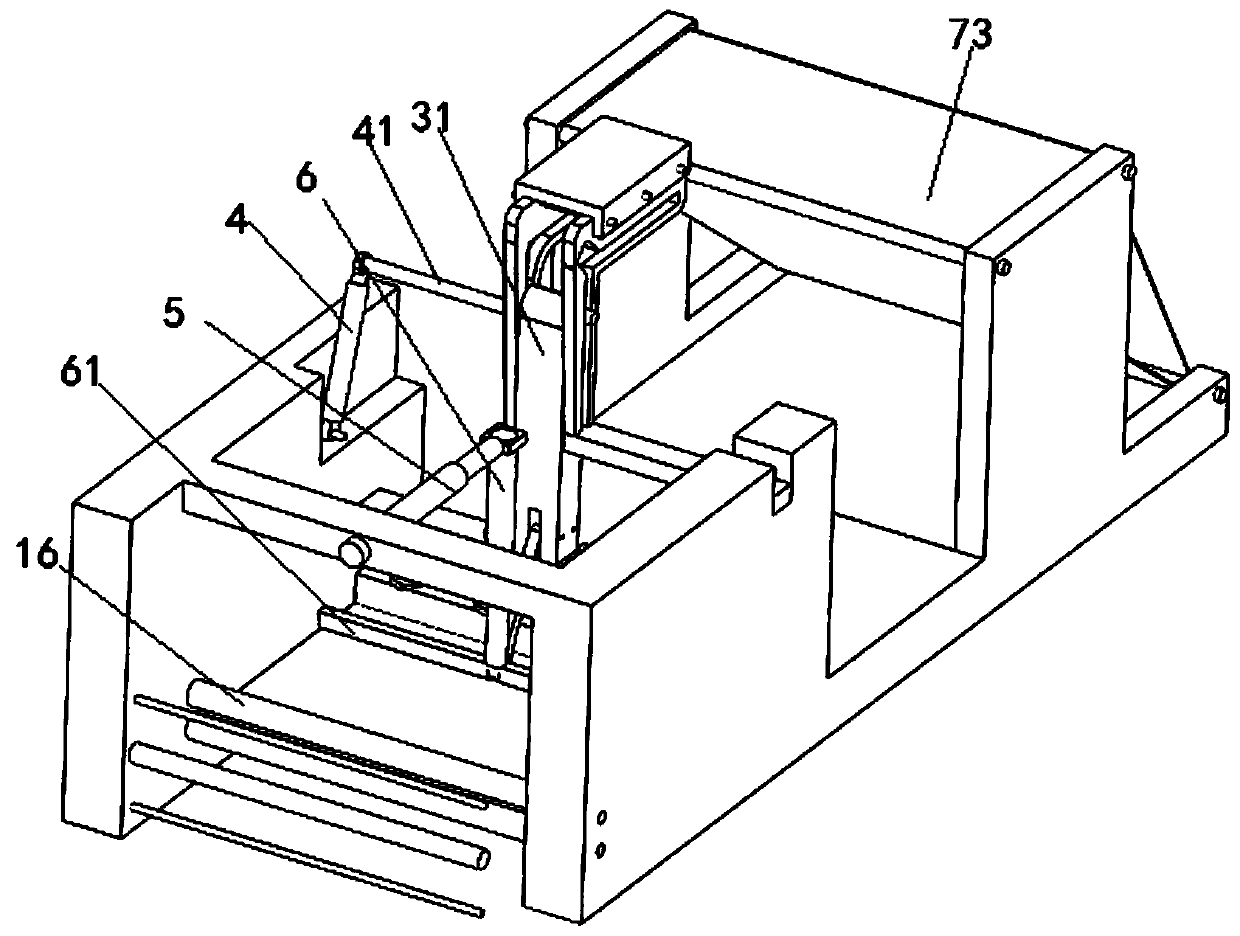

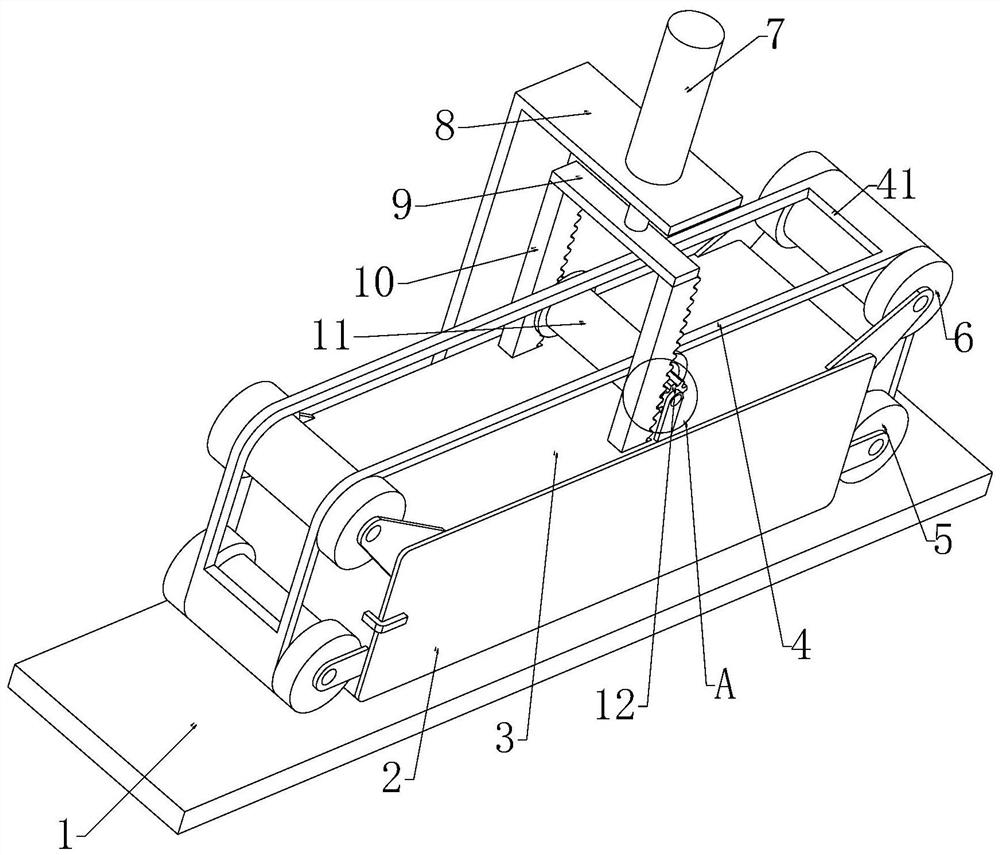

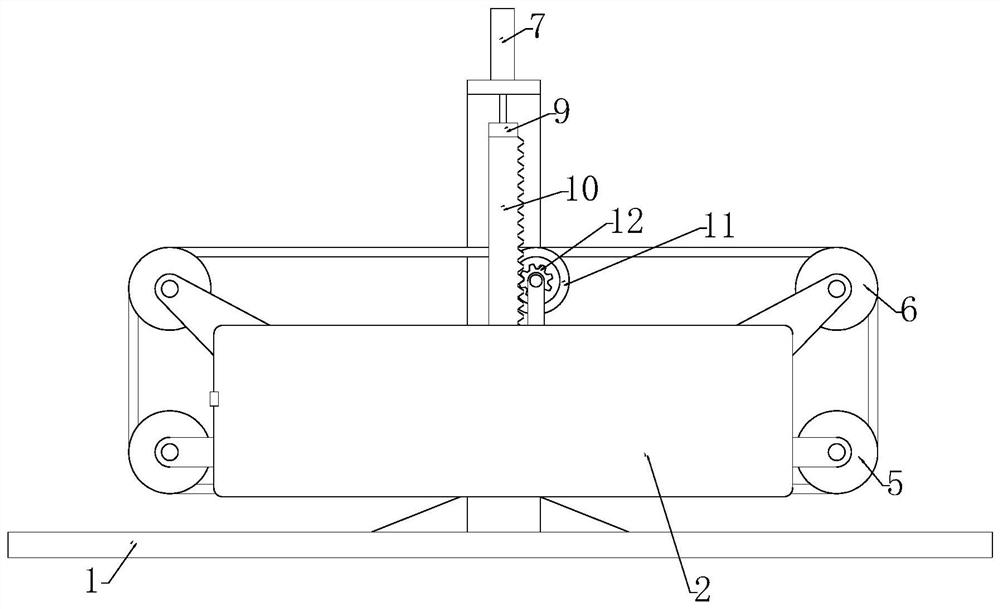

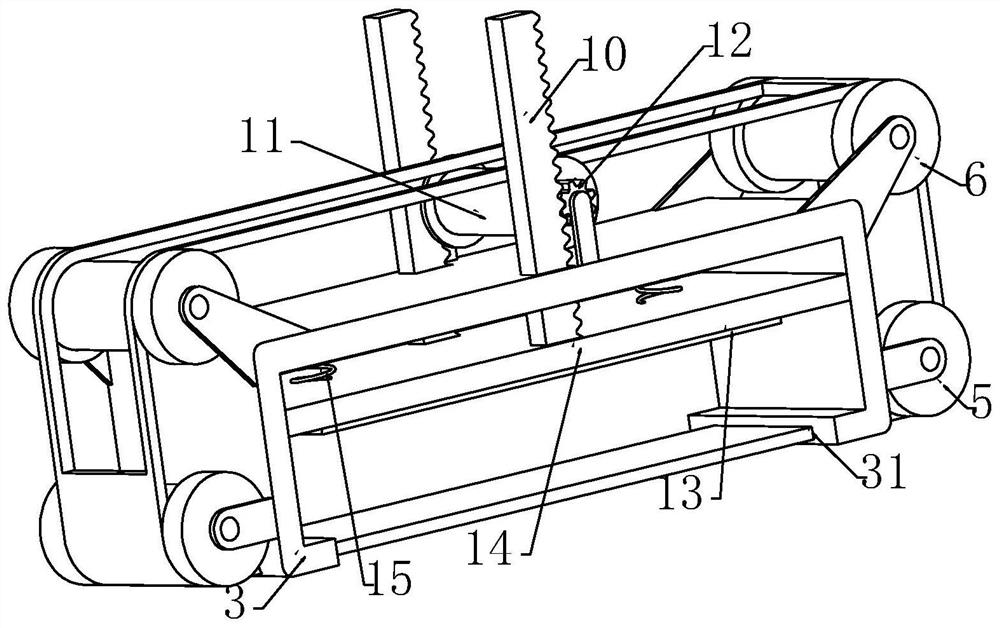

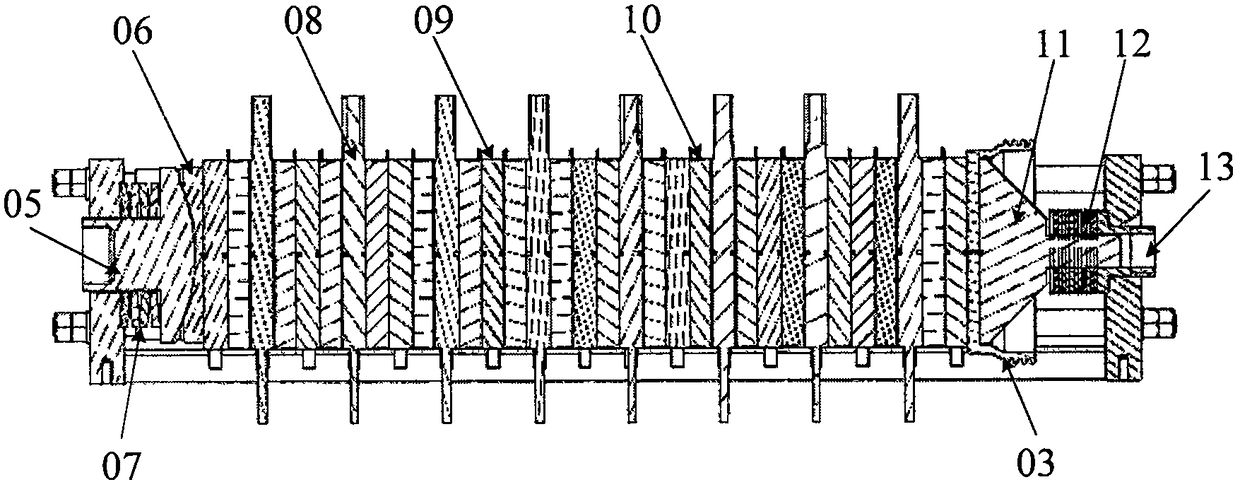

Feed smashing equipment

InactiveCN111185266AEasy to cutPressing to achieveFeeding-stuffCuttersAgricultural engineeringControl theory

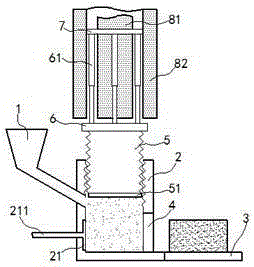

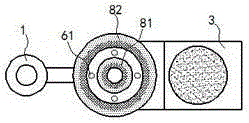

The invention relates to the field of feed, in particular to feed smashing equipment. Mixture of soybean and bean cake can be smashed through a smashing and combining body; the smashing effect can beadjusted according to actual conditions; straw can be cut through a cutting and combining body; the cutting length of the straw can be adjusted according to actual conditions; and the machining speedof the device can be adjusted; the feed smashing equipment comprises the smashing and combining body, the cutting and combining body and a bottom frame and combining body, when a second bevel gear rotates, a first bevel gear is driven, then a middle-end rectangular frame is driven to move through an N-shaped frame, and through the action of a rectangular frame clamping groove and a driving inner sliding rod, a hinged connection block is driven and a driving rectangular rod is driven to move, then a first rectangular sliding rod is driven to slide along a second middle end support, then a firstclamping and moving rod and a second clamping and moving rod drive the straw to move forwards in a stepping mode along a cutting outer frame at the same time, straw transportation is completed, strawcutting is facilitated through a cutting blade, and straw pressing is achieved through a pressing roller.

Owner:许冬梅

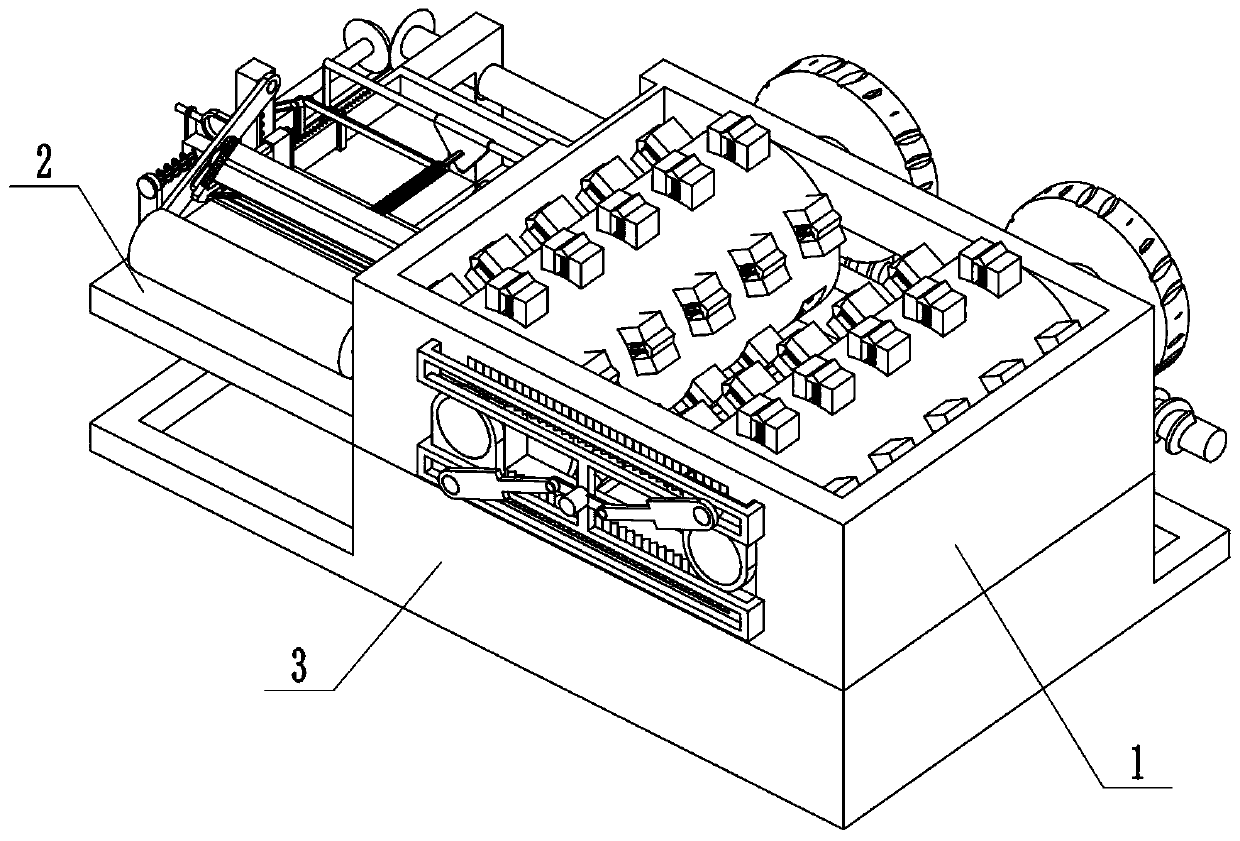

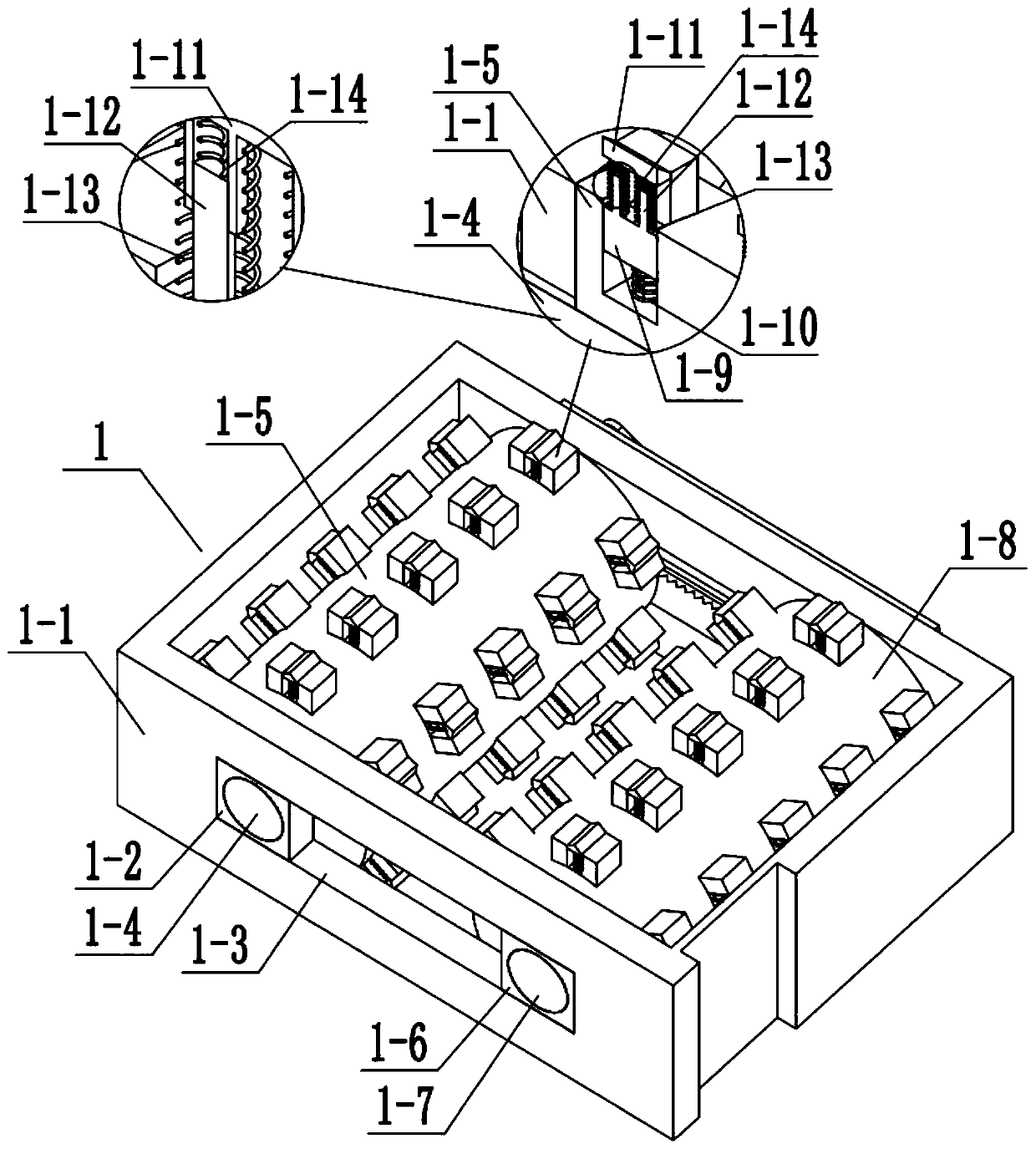

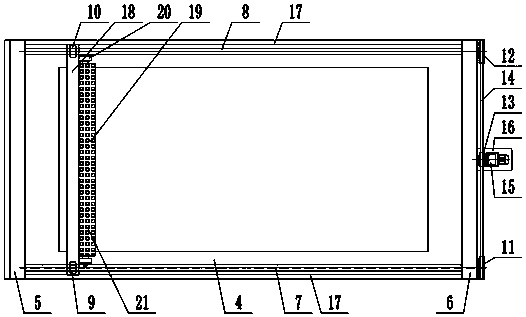

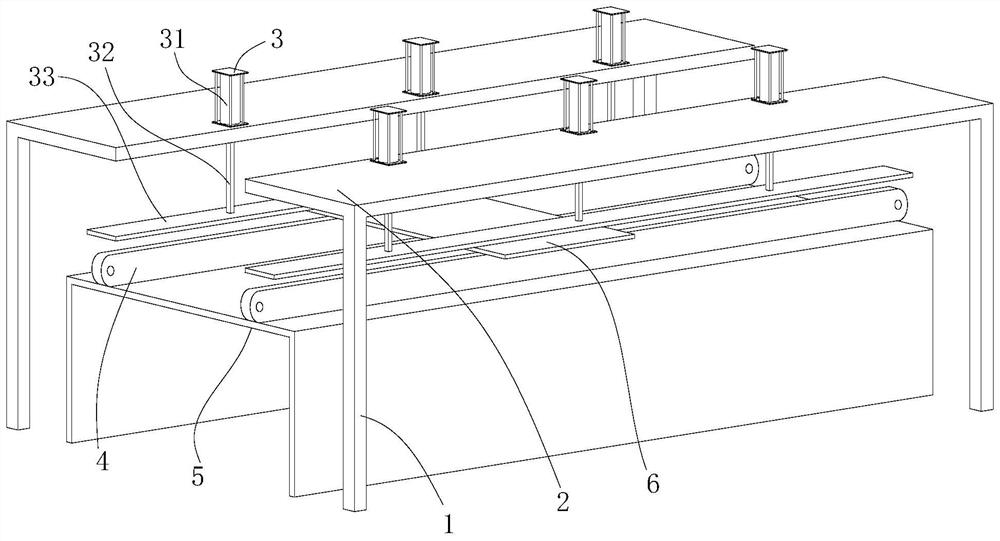

Gelatinizing and pressing-fit device for plate

InactiveCN108722778APressing to achievePressing is beneficial to realizeLiquid surface applicatorsMaterial gluingThree stageEngineering

The invention provides a gelatinizing and pressing-fit device for a plate, and belongs to the technical field of plate processing. The gelatinizing and pressing-fit device comprises a pressing-fit mechanism, a gelatinizing mechanism and a glue liquid control mechanism. A gelatinizing support of the gelatinizing mechanism is arranged on a guide rail in a left-right sliding manner, and a gelatinizing roll is rotationally arranged between two gelatinizing roll supporting plates. A first lead screw and a first lead screw nut are in threaded connection, and a second lead screw and a second lead screw nut are in threaded connection. The pressing-fit mechanism is arranged over the gelatinizing mechanism, and first sliding sleeve plate, a second sliding sleeve plate and a third sliding sleeve plate of the pressing-fit mechanism are arranged from top to bottom and arranged on a pressing rod in a vertical sliding manner. The rigidity of a first spring is smaller than that of a second spring, andthe rigidity of the second spring is smaller than that of a third spring. The gelatinizing and pressing-fit device is fast and even in gelatinizing, pressing-fit force changes can be divided into three stages, the pressing-fit force is in a gradually increasing broken line type, the pressing-fit force stability is good, and the gelatinizing and pressing-fit effect of the plate is greatly improved.

Owner:费晓杰

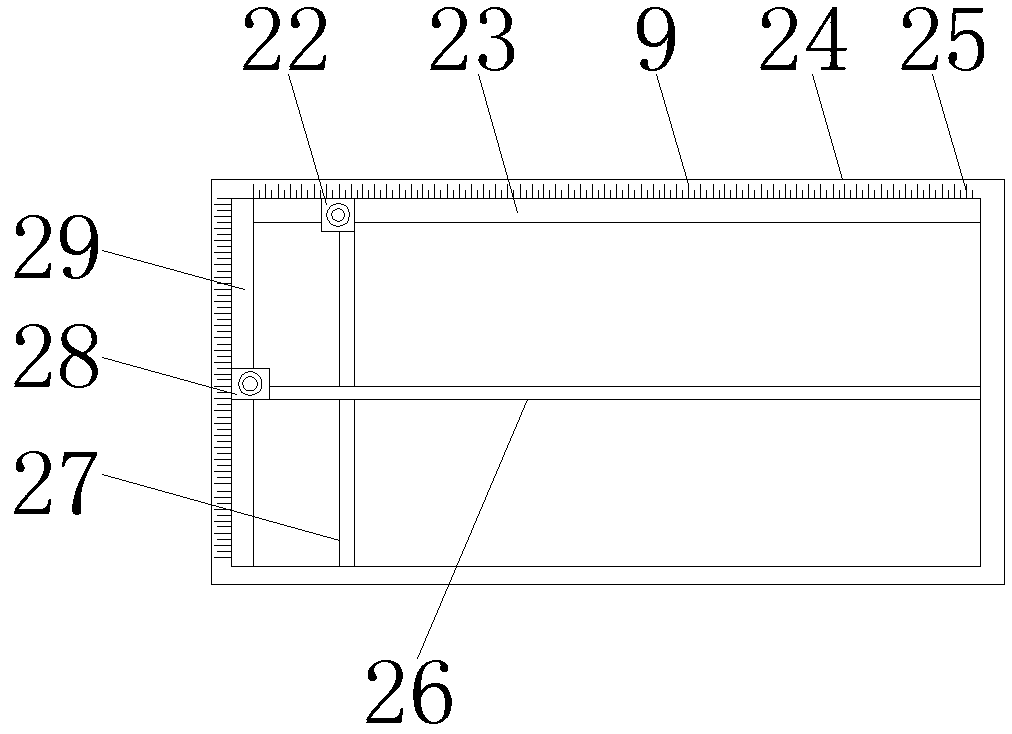

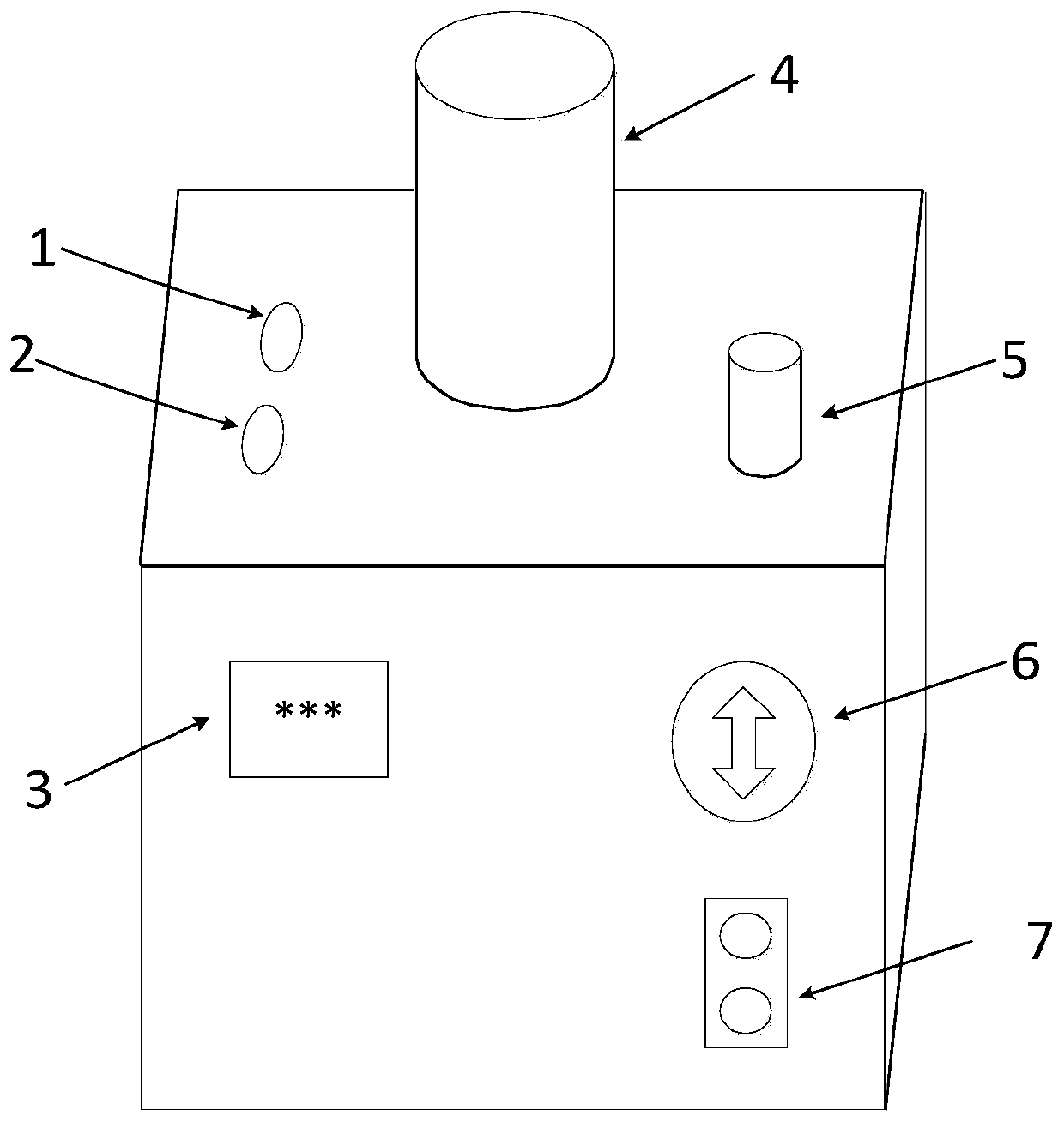

Print circuit board laminating device

PendingCN108541151AImprove practicalityEasy to operateMultilayer circuit manufactureSteel platesPrinted circuit board

The invention discloses a print circuit board laminating device. The print circuit board laminating device comprises a second air cylinder, a first slider, a second slider, a first air cylinder, a steel plate and a first heating plate. A piston rod is driven by the second air cylinder to extend so as to drive a frame to move upwards to the portion above the steel plate, and the bottom of a secondlimiting plate is made to be flush with the top of the steel plate. According to the size of a to-be-laminated print circuit board, the position of the print circuit board on the top of the steel plate is calculated, the first slider and the second slider are further driven to move, so that a first limiting plate and the second limiting plate are moved to a designated position, it is achieved thatthe to-be-laminated print circuit board is identified on the top of the steel plate, and the operation is simple; the print circuit board is further placed on the top of the steel plate, the two sides of the circuit board are made to make contact with the first limiting plate and the second limiting plate respectively, accordingly, it is achieved that the circuit board is limited on the top of the steel plate, the operation is simple, it is not required that the position of the circuit board is manually adjusted, and a lot of time is saved.

Owner:湖北荣宝电子科技有限公司

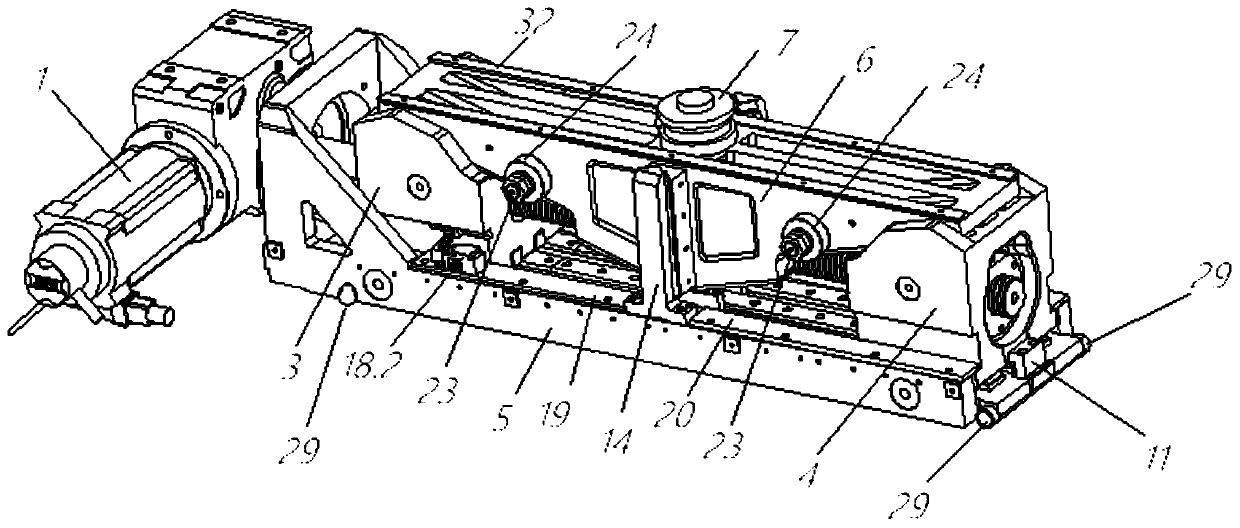

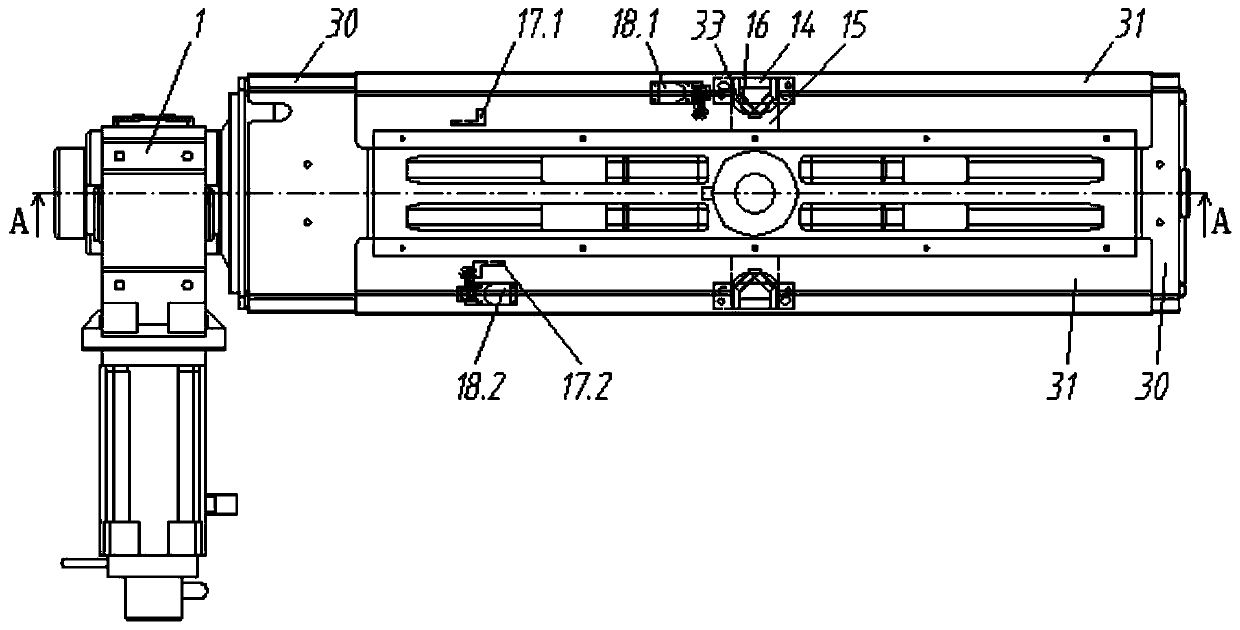

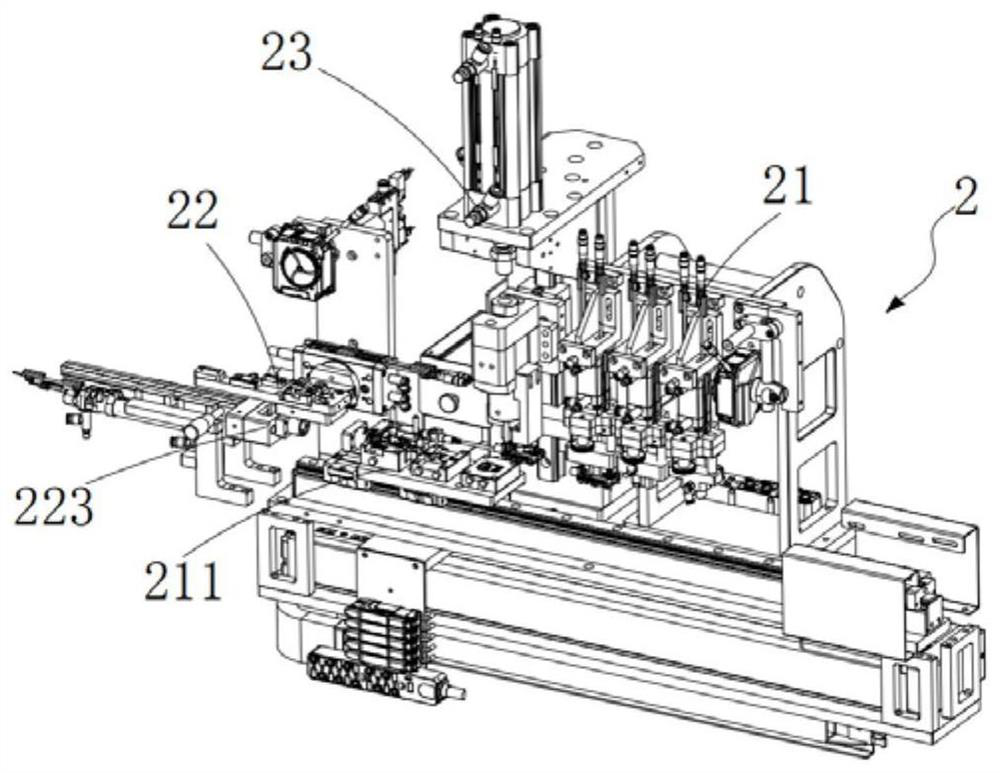

Film tearing assembling equipment

PendingCN110202349APressing to achieveRealize automatic feedingLamination ancillary operationsLaminationEngineeringLiquid crystal

The invention provides film tearing assembling equipment. The film tearing assembling equipment comprises a machine frame, a rotating disc mechanism arranged on the machine frame, an arranging feedingmechanism, a rotary riveting feeding mechanism, a film tearing mechanism, a pressing mechanism and a discharging mechanism, wherein the arranging feeding mechanism, the rotary riveting feeding mechanism, the film tearing mechanism, the pressing mechanism and the discharging mechanism are arranged on the periphery of the rotating disc mechanism in the circumferential direction. The rotary rivetingfeeding mechanism feeds a liquid crystal screen, the rotating disc mechanism rotates, the liquid crystal screen is rotated to the next station, the film tearing mechanism is used for tearing off a protective film on the liquid crystal screen, the arranging feeding mechanism is used for feeding a metal frame, the pressing mechanism is used for clamping and pressing the metal frame to the peripheryof the liquid crystal screen, then the discharging mechanism is used for discharging the liquid crystal screen with the metal frame pressed, so that automatic feeding of the liquid crystal screen andthe metal frame, film tearing, metal frame pressing are realized, the intelligent production is realized, the labor is saved, and the production is efficient.

Owner:SUZHOU BEIAITE AUTOMATION SCI & TECH

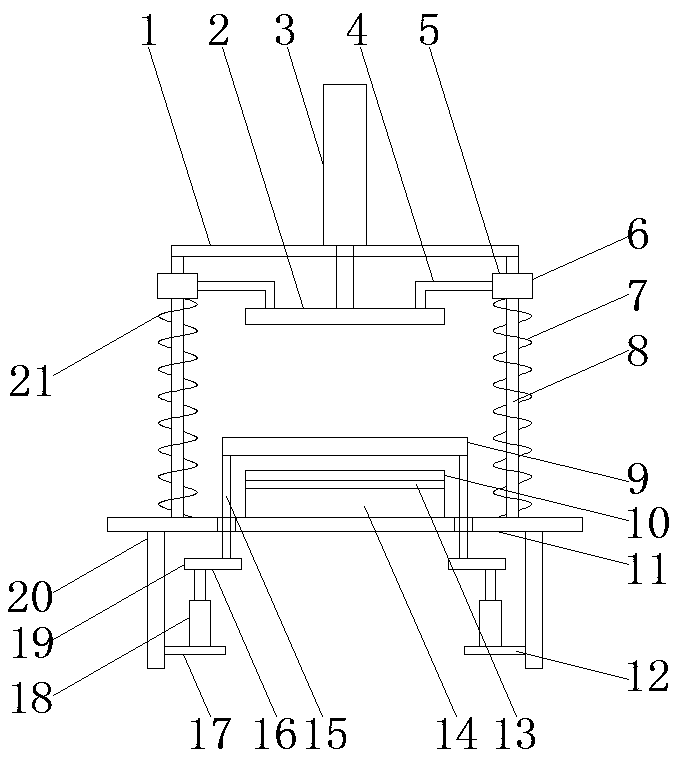

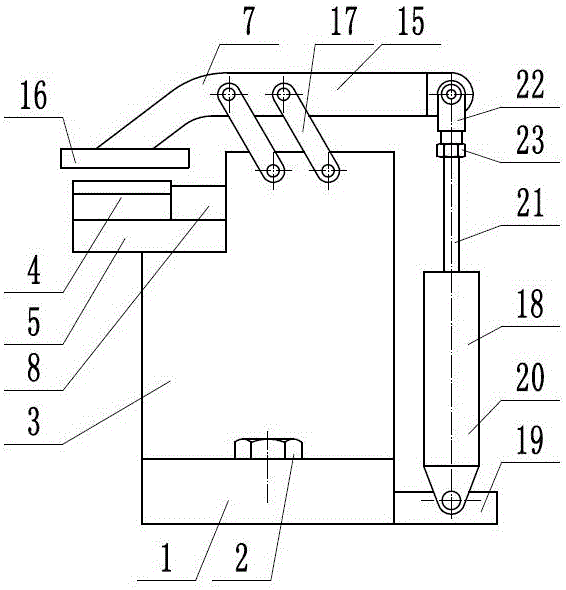

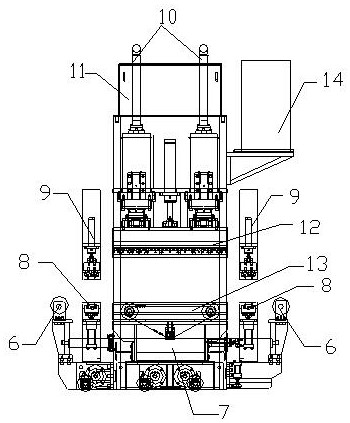

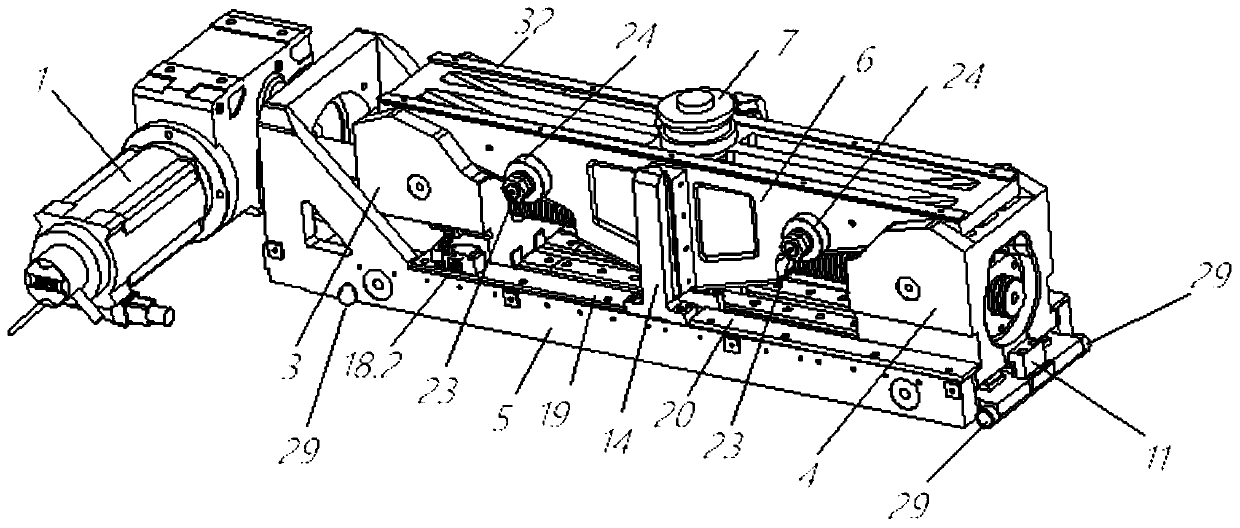

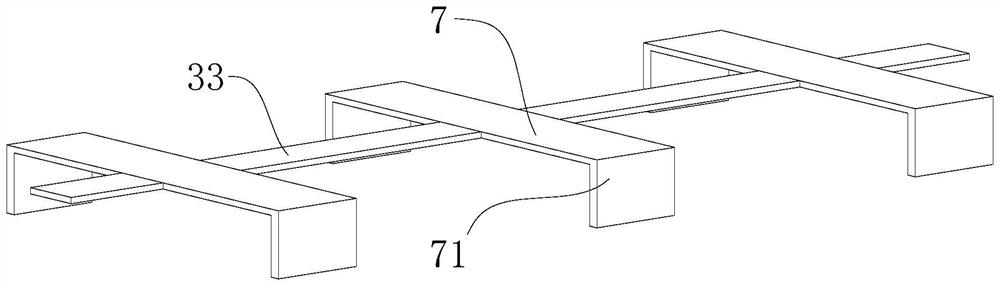

Intermittent press-fitting device

InactiveCN106078603APressing to achieveReduce pinch injuriesWork holdersPress ramEngineeringCylinder block

The invention provides an intermittent press-fitting device and belongs to the technical field of machining. The intermittent press-fitting device comprises a press-fitting platform, a clamping mechanism and a press-fitting mechanism. The press-fitting platform is fixed to one side of a rack. A rear supporting cushion block of the clamping mechanism is fixed to the press-fitting platform and located behind a workpiece. A left clamping assembly and a right clamping assembly are symmetrically arranged on the left side and the right side of the workpiece. A driving cylinder of the press-fitting mechanism comprises a cylinder block, a piston rod, a connecting support lug and a lock nut. The lower end of the cylinder block is hinged to a cylinder supporting seat. The cylinder supporting seat is fixed to one side of a supporting base. The connecting support lug is in threaded connection with the upper end of the piston rod and is locked through the lock nut. The connecting support lug is hinged to one end of a pressing plate fulcrum bar. A pressing plate is arranged at the other end of the pressing plate fulcrum bar. The upper ends of two rocking bars are hinged to the pressing plate fulcrum bar. The lower ends of the rocking bars are hinged to the rack. The intermittent press-fitting device can conduct intermittent press-fitting on the workpiece, and is reasonable in structure, adjustable in press-fitting force and high in applicability.

Owner:徐晓杰

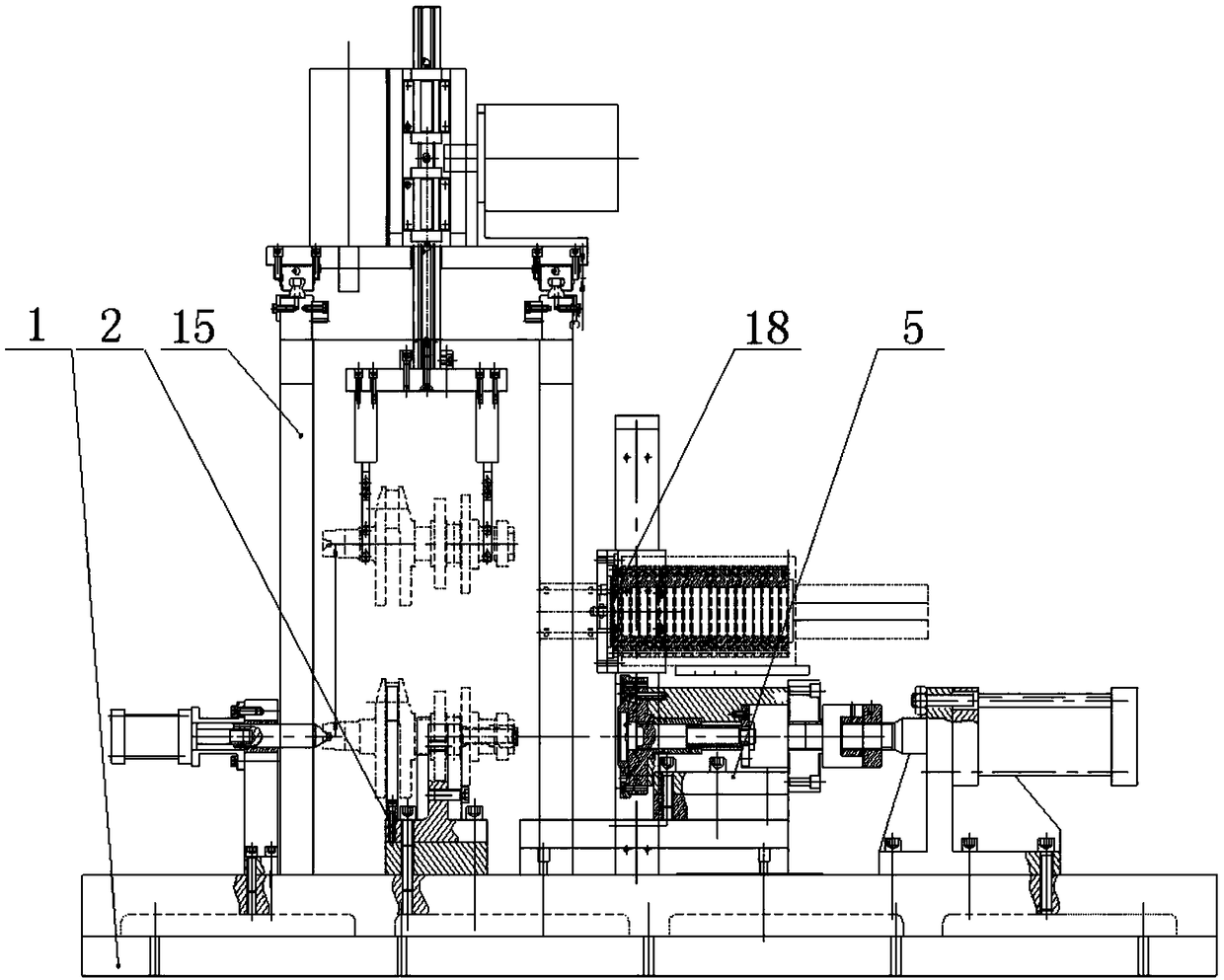

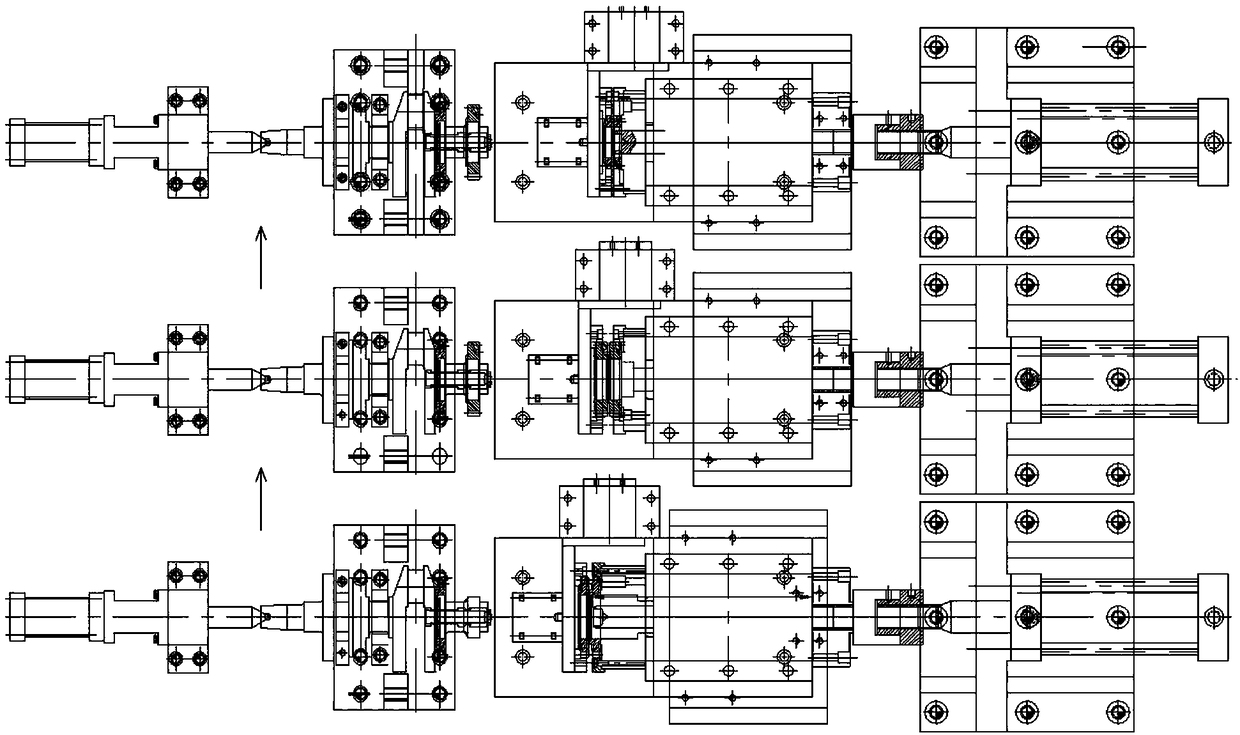

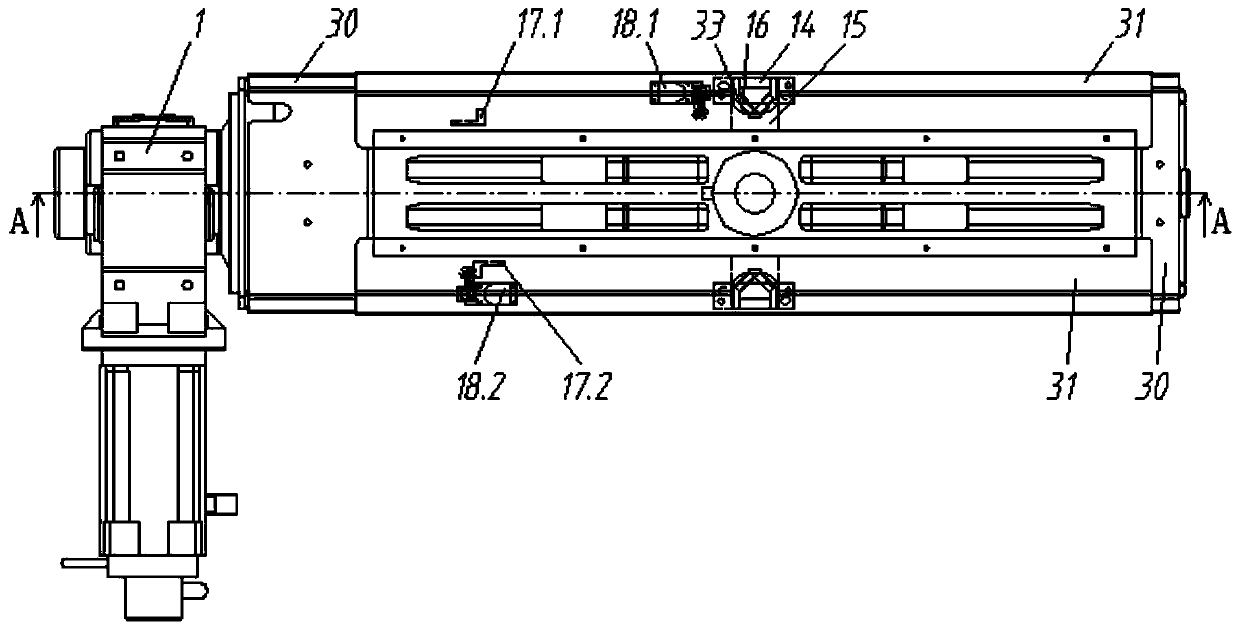

Press fitting device for crankshaft gears

PendingCN108381169APress-fitting is efficiently achievedPressing to achieveAssembly machinesEngineeringMechanical engineering

The invention discloses a press fitting device for crankshaft gears. The press fitting device comprises a lathe bed, a plurality of clamps, gear press-fitting mechanisms and crankshaft transferring mechanisms, wherein the clamps are arranged on the lathe bed and are used for installing workpieces on press fitting stations, the gear press-fitting mechanisms are arranged on the lathe bed and are used for carrying out press fitting on the corresponding gears on the workpieces on the corresponding press-fitting stations, and the crankshaft transferring mechanisms are arranged on the lathe bed andare used for sequentially installing the workpieces on the clamps according to a preset process sequence. The press fitting device for the crankshaft gears has the advantages that all the workpieces can be arranged on the different press fitting stations through the multiple clamps, the circulation of all the workpieces among the different press-fitting stations can be realized through the crankshaft transferring mechanisms, meanwhile, press fitting of the corresponding gears of the workpieces on all the press fitting stations can be realized through the gear press-fitting mechanisms, and therefore press fitting of all the gears on the workpieces (crankshafts) can be rapidly and efficiently realized, the manual labor can be greatly reduced, and the process flow can be shortened.

Owner:青岛德盛机械制造有限公司

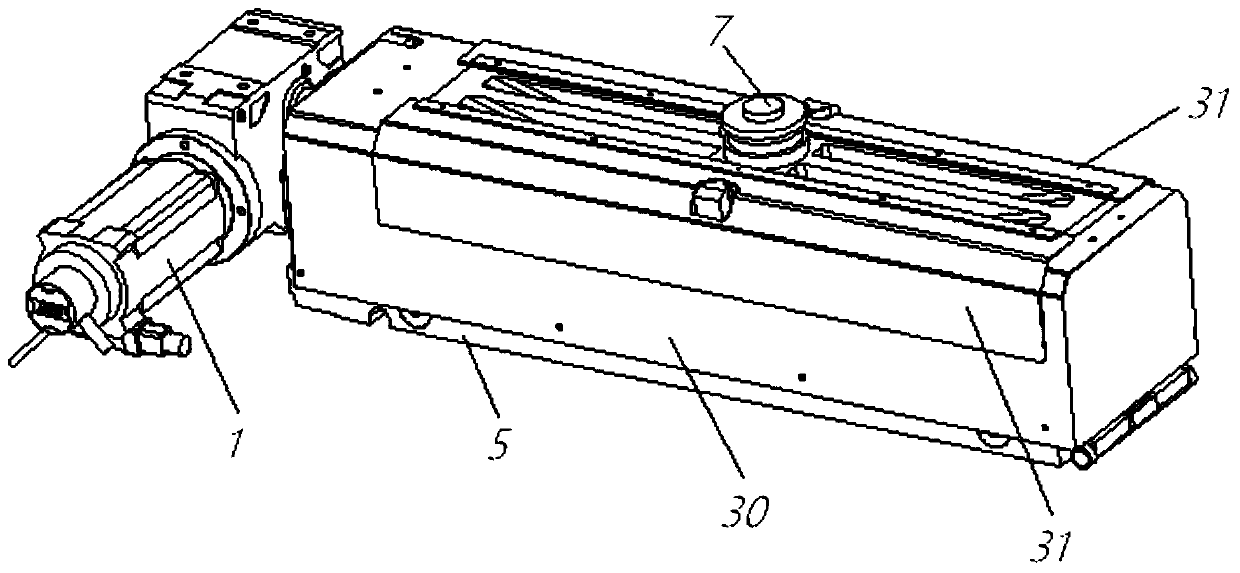

Servo drive laminating device

ActiveCN110216182APressing to achieveMeet different location requirementsMetal working apparatusControl systemBall screw

The invention provides a servo drive laminating device, which solves the problem of the power source of a special laminating machine during the laminating process; the device comprises an installationbase, a servo motor, a bidirectional ball screw nut pair, two cam sliding blocks driven by the bidirectional ball screw nut pair, a sliding block, a weighing sensor, an external reference limiting block, an internal reference limiting block, a joint injection oil cup, a longitudinal guide mechanism composed of a V-shaped convex guide rod and a V-shaped concave guide plate, a collision block, a stroke switch, a shaft, a support type roller, a straight-through injection oil cup, etc., the device can realize the different position requirements of the upward movement of a concave mold according to the product laminating process requirement, so multiple flanging can be finished and the laminating is realized; the weighing sensor feeds back the condition of the laminating force at different positions of the control system in real time.

Owner:CHINA FIRST AUTOMOBILE +1

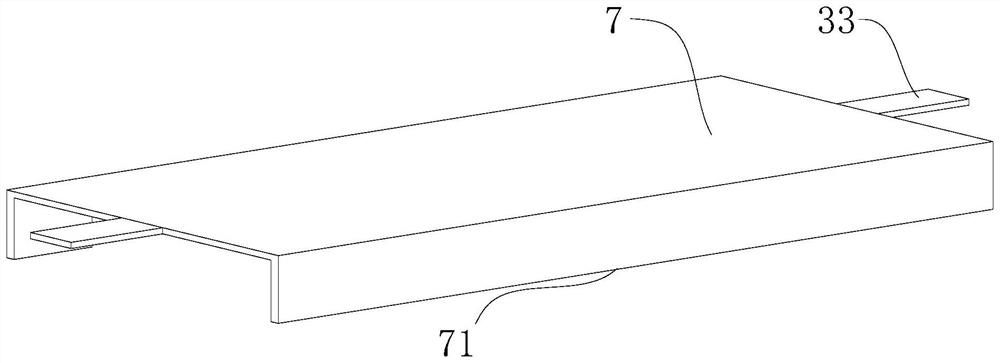

Multi-layer composite type insulating plate composite production line

InactiveCN110614774APress tightlyNo secondary processing requiredClimate change adaptationInsulation improvementProduction lineElastic compression

The invention discloses a multi-layer composite type insulating plate composite production line which comprises a support bottom plate. A first support plate and a second support plate opposite to each other are integrally connected and fixed on the two side walls at one end of the support bottom plate; a limiting adjusting mechanism is mounted on one side of the surface of the first support plate; a press fit plate moving mechanism is mounted on the limiting adjusting mechanism; an adjusting air cylinder is hinged to the side wall of one end of the second support plate; and the power output end of the adjusting air cylinder is connected with the press fit plate moving mechanism through a rotary shaft. According to the multi-layer composite type insulating plate composite production line,two driving rollers are arranged to carry out first-time press fit on a composite plate; and after press fit, a compression roller column is arranged on the press fit plate moving mechanism to carry out second-time press fit on the composite plate through elastic compression during the pull-in process, so that press fit among three layers of a prepared insulating plate is tight.

Owner:安徽群升建筑工程有限公司

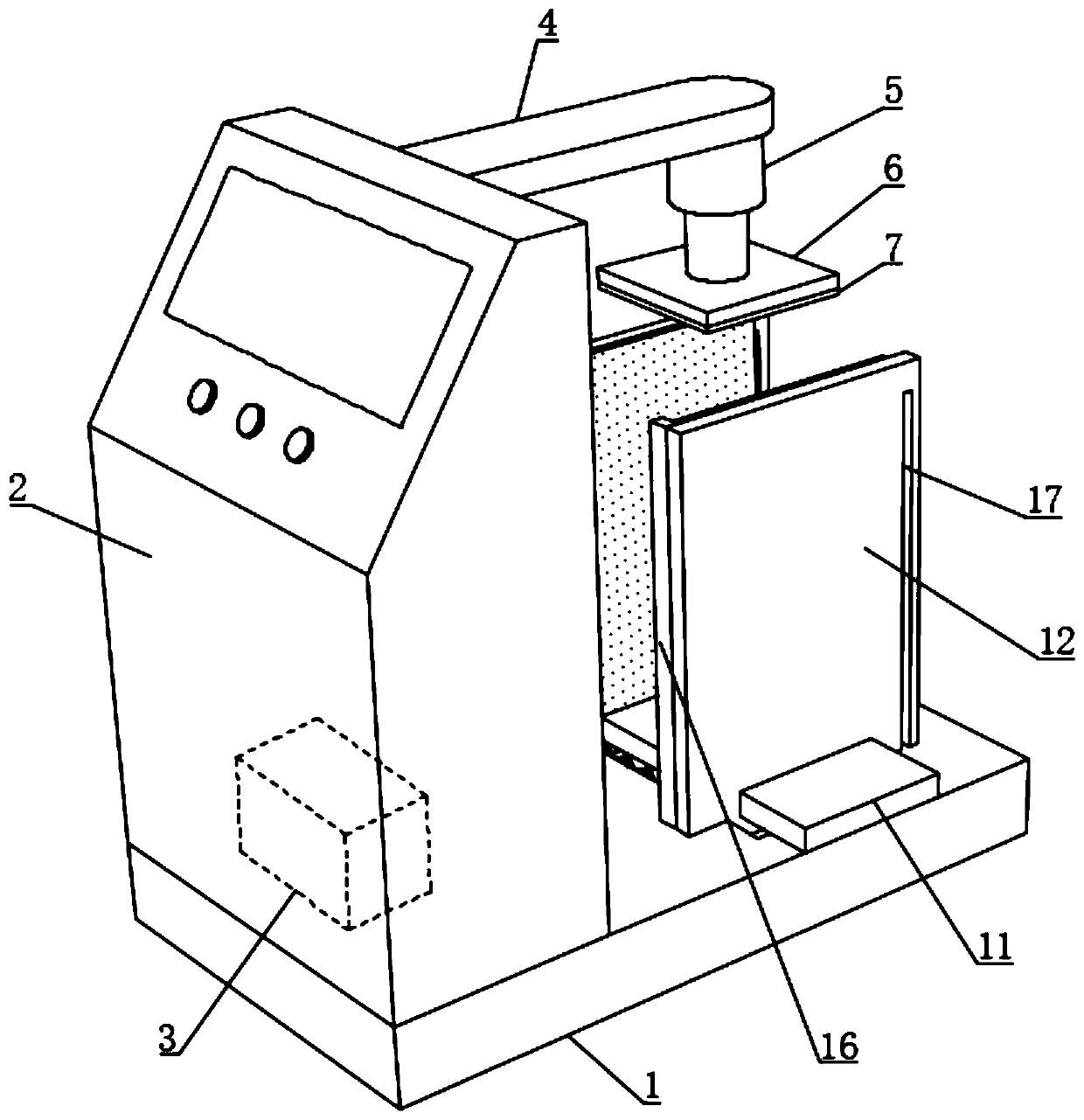

Testing device and testing method for Internet of Things semiconductor equipment

InactiveCN111006616AImprove detection efficiencyRealize detectionUsing optical meansLaser imagingEngineering

The invention discloses a testing device and a testing method for Internet of Things semiconductor equipment. The invention belongs to the technical field of semiconductor equipment detection. The testing device comprises a testing host; a control panel is arranged on the test host; the lower end of the test host is fixedly connected with a base; a main control board is installed in the test host;a pair of parallel clamping plates is arranged on the upper side of the base; the clamping plates are positioned at one side of the test host; a main sliding groove is dug in the upper end of the base; and the lower end of eachclamping plate is slidably connected into the main sliding groove. According to the invention, a plurality of semiconductor equipments are stacked together to form a semiconductor equipment group; the semiconductor equipment group is scanned and imaged through the laser imaging technology, so that the surface flatness of multiple pieces of semiconductor equipment can bedetected at one time, multiple pieces of semiconductor equipment which do not meet the requirements can be quickly and accurately detected at one time, and the detection efficiency of the semiconductor equipment is greatly improved.

Owner:王东

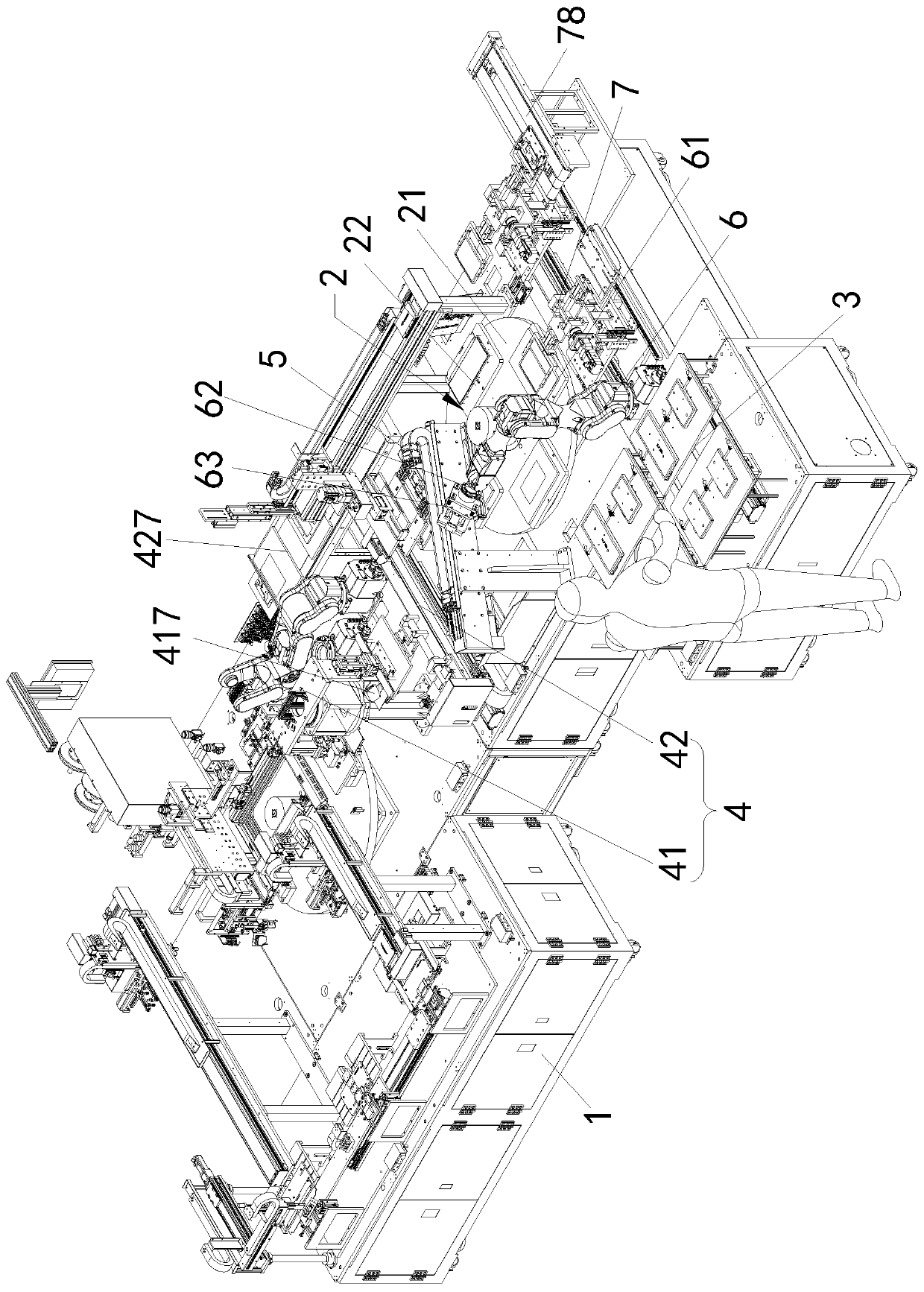

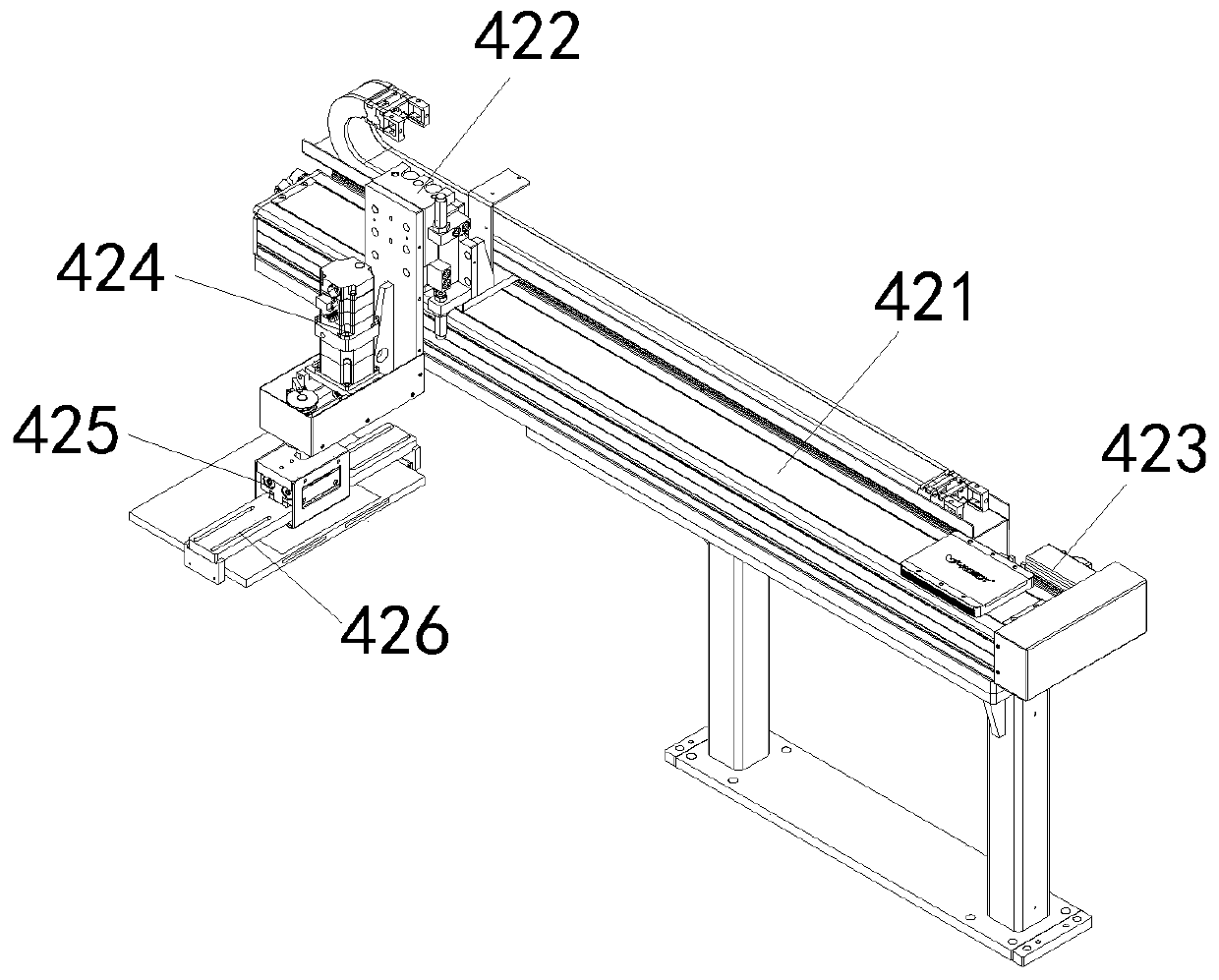

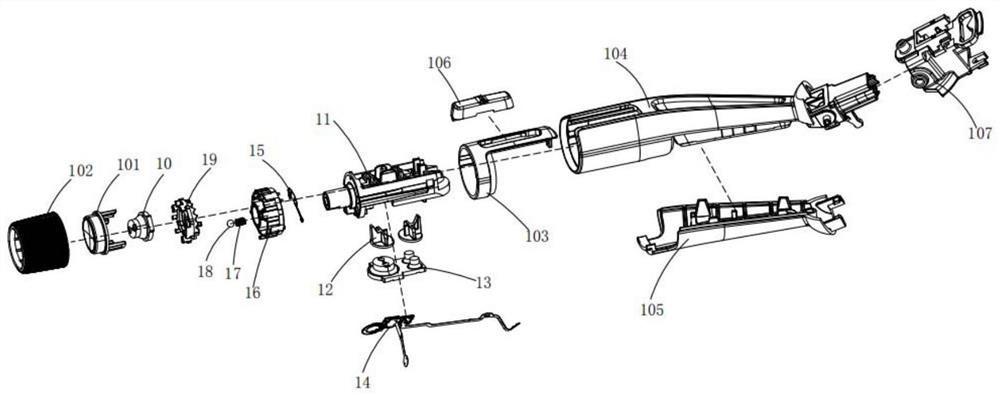

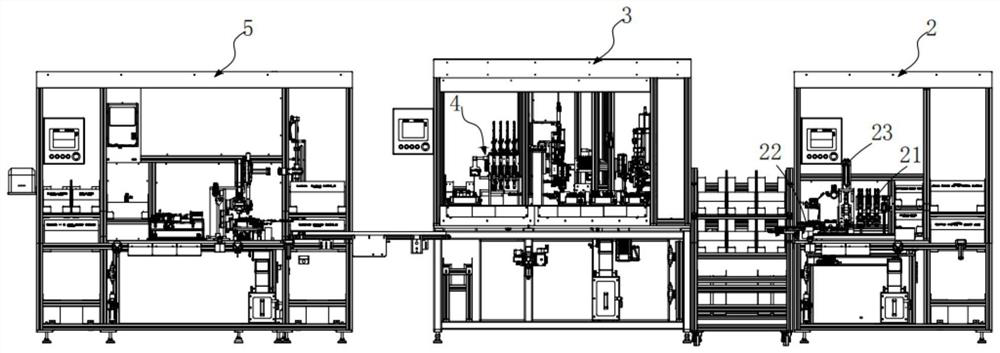

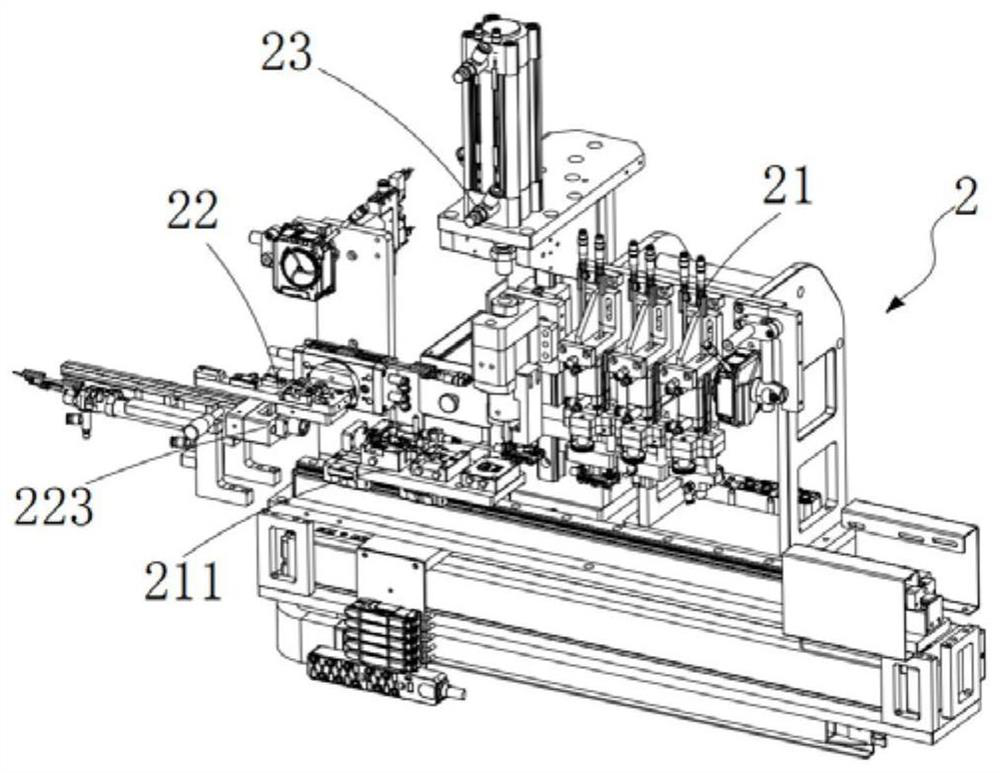

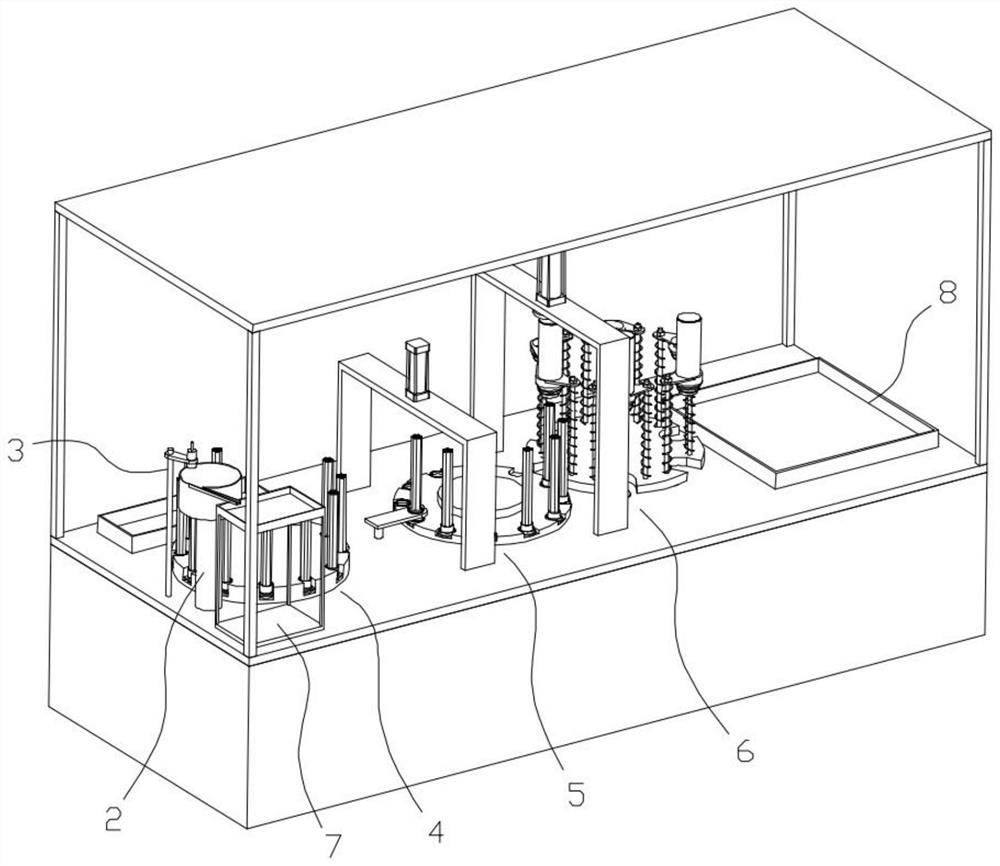

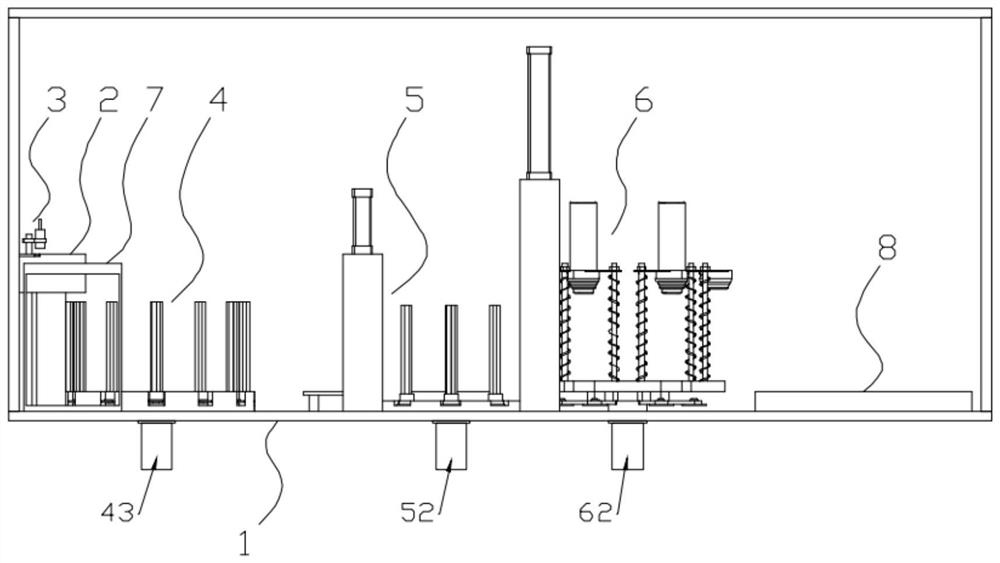

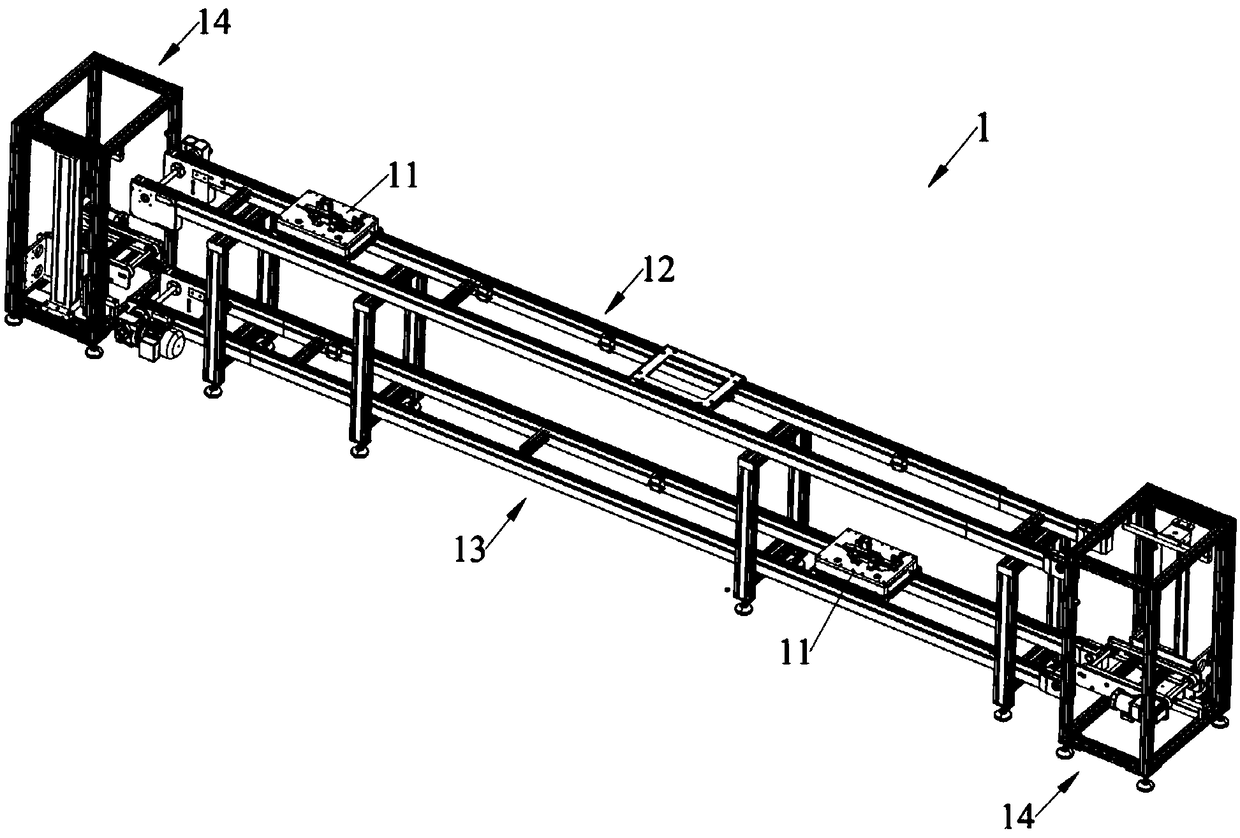

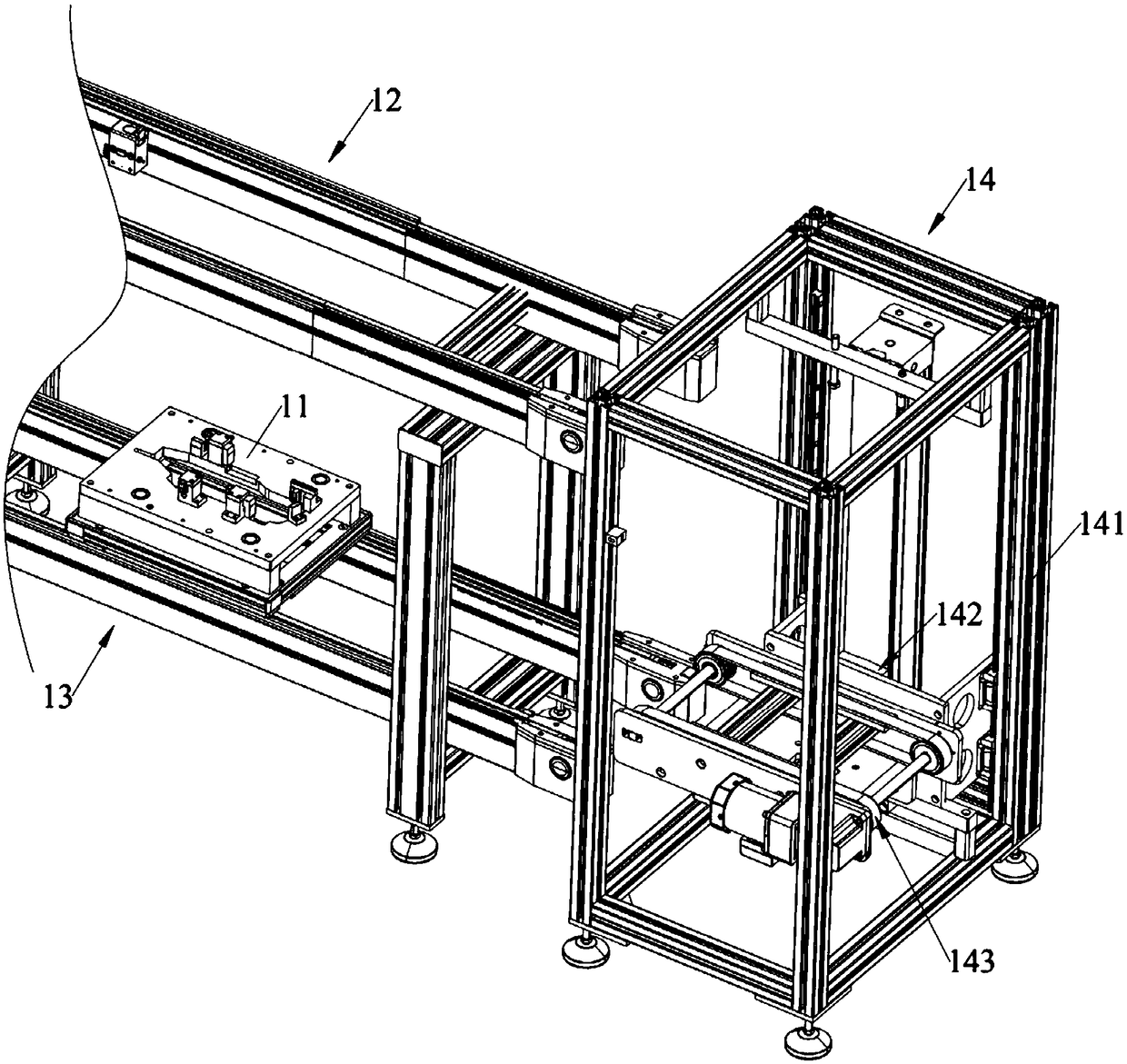

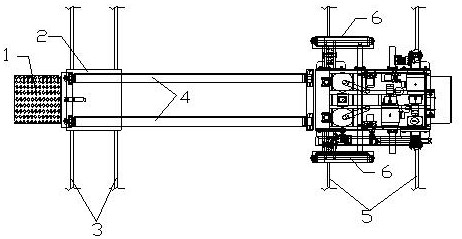

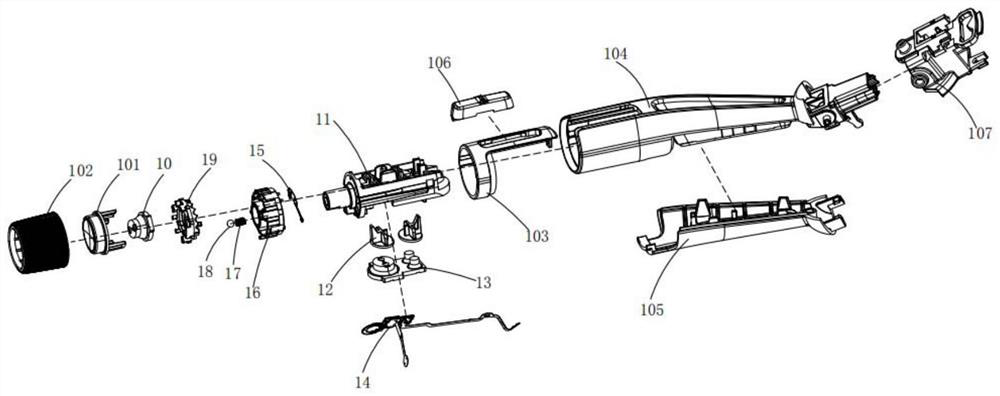

Assembly processing line and assembly process of left gear lever handle for automobile steering wheel

ActiveCN112222825AReduce manual operationsImprove assembly accuracyAssembly machinesSteering wheelStructural engineering

The invention relates to the technical field of automobile steering wheel assembly, in particular to an assembly processing line and an assembly process of a left gear lever handle for an automobile steering wheel. The assembly processing line used for assembling the left gear lever handle comprises a pre-assembling assembly, a rotary assembling assembly, an adsorption press-fitting assembly and alocking and pressing assembly which are sequentially arranged according to the assembling sequence of the left gear lever handle, through combined use of the pre-assembling assembly, the rotary assembling assembly, the adsorption press-fitting assembly and the locking and pressing assembly, machined parts can be automatically assembled in each assembling step, so that manual operation is reduced,the assembling precision and the assembling quality are improved, the technical problem of low assembling precision caused by manual factors in the assembling process is solved, and the defective rate is effectively reduced.

Owner:浙江金麦特自动化系统有限公司

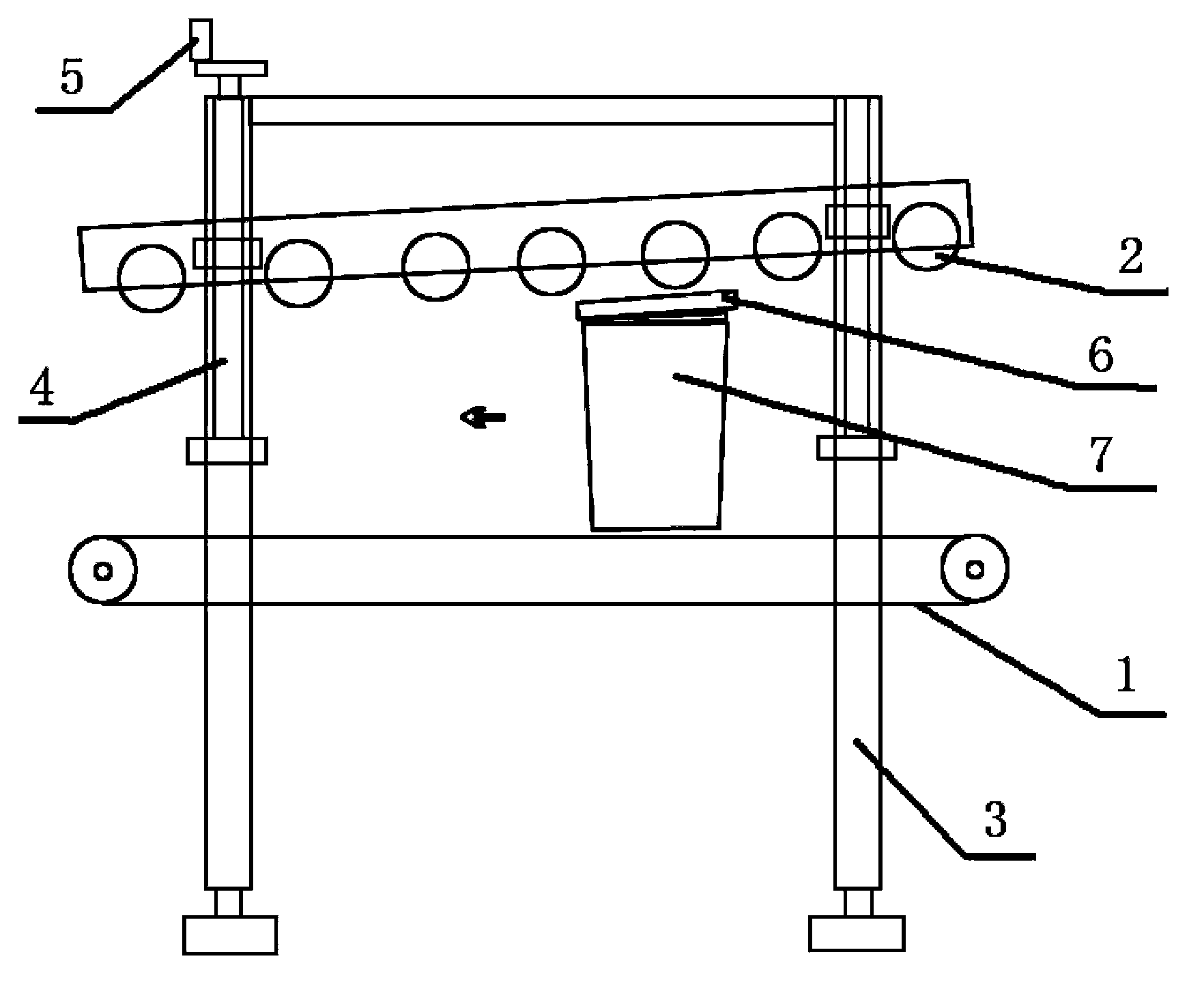

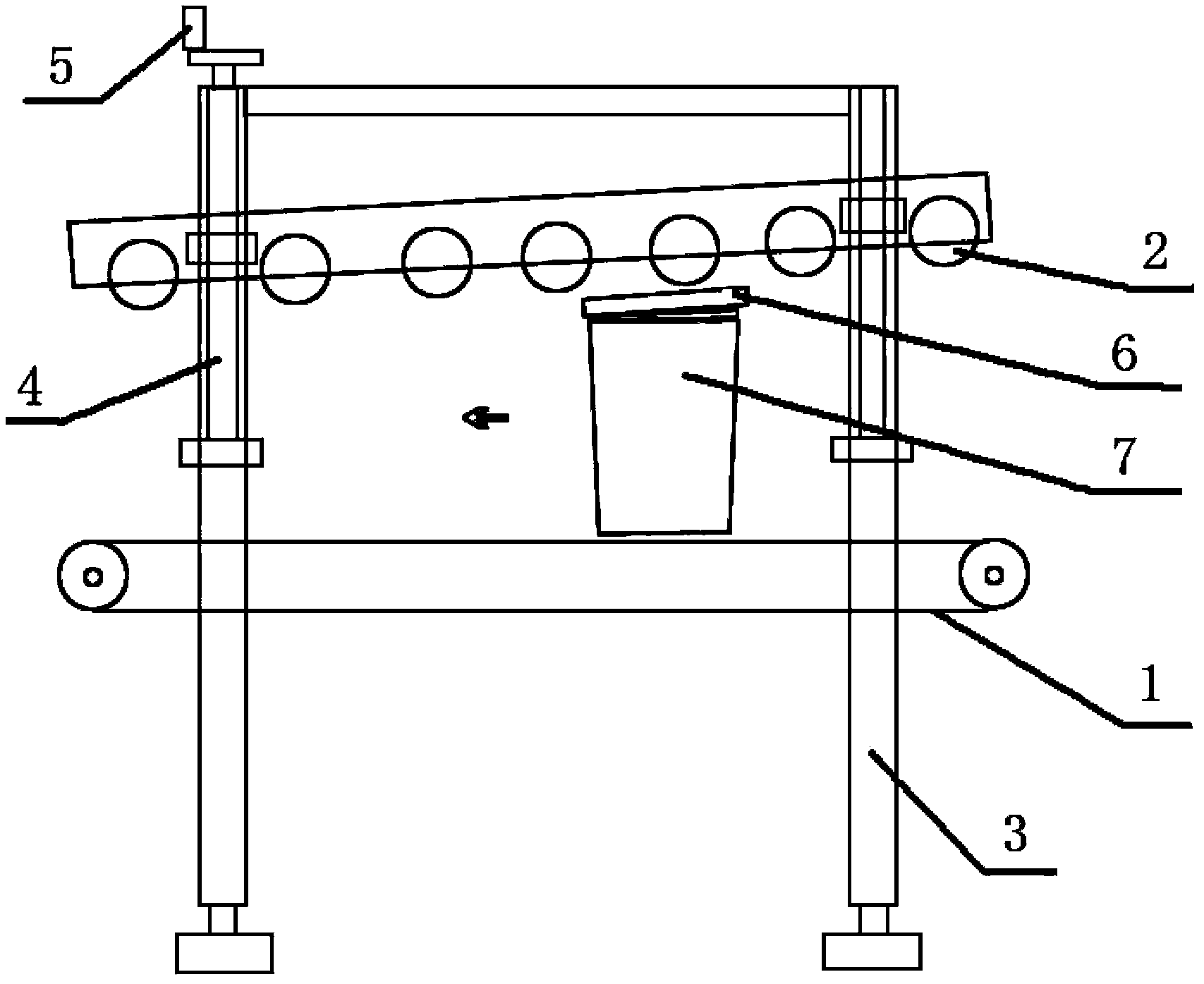

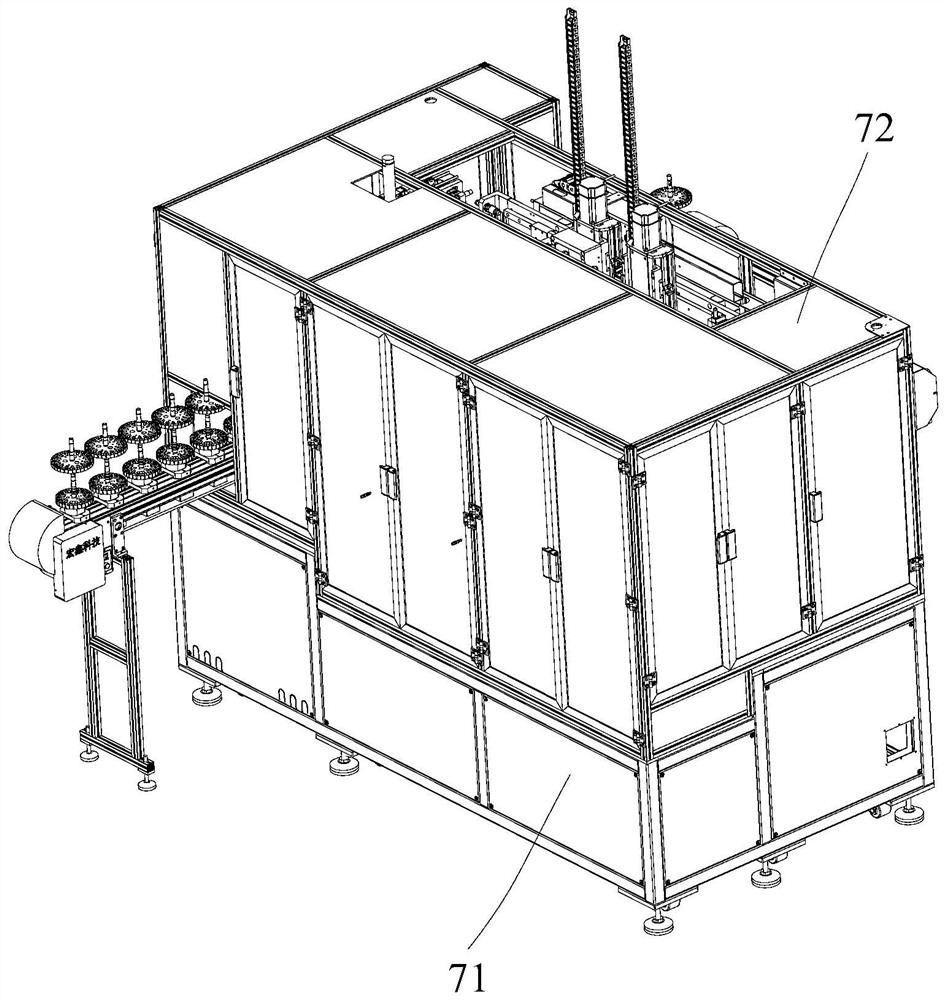

Automatic cover pressing machine

InactiveCN103663312AHeight adjustableSo as not to damageCapsClosure using capsElectric machineryEngineering

The invention provides an automatic cover pressing machine. According to the automatic cover pressing machine, a barrel cover does not blow up, the press-fitting efficiency is high and cost is low. The automatic cover pressing machine comprises a conveying belt for conveying a barrel and a roller which is located above the conveying belt and is used for squeezing the barrel cover when the barrel and the barrel cover pass through a support, wherein the roller is installed on the support, the support is arranged on the conveying belt in a cross-over mode, and the conveying belt is driven by a motor. Due to the fact that a guide included angle theta which is larger than or equal to 7 degrees and smaller than or equal to 15 degrees and allows the barrel to pass through is formed between the conveying belt and a roller plate, the roller rolls on the barrel cover during press-fitting, air is gradually exhausted in the process, and accordingly the barrel cover does not blow up, and stacking is facilitated when the barrels are stacked and transported. Pressure on the barrel gradually increases, and the barrel is protected against being damaged in the squeezing process in the largest degree under the same condition. The automatic cover pressing machine is simple in structure and ingenious in concept; when the automatic cover pressing machine operates, what is needed is to rotate the conveying belt, the roller can press the cover without power, and accordingly operation cost is reduced.

Owner:天津滨海新区大港圣益油脂有限公司

Lid-pressing device

InactiveCN104291250AHeight adjustableSo as not to damageCapsClosure using capsEngineeringConveyor belt

The invention provides a lid-pressing device. The lid-pressing device comprises a conveyor belt for conveying a bucket body and rollers located above the conveyor belt for pressing a bucket lid when the bucket body and the bucket lid pass through supports. The rollers are installed on the supports. The supports straddle the conveyor belt. The conveyor belt is driven by a motor. Since a deflection included angle Theta allowing the bucket body to pass through exists between the conveyor belt and a roller plate, 7 degrees <= Theta <= 15 degrees, so that the rollers roll on the bucket lid during pressing. In this process, the air is gradually exhausted, so that air blowing phenomenon does not happen to the bucket lid, and the bucket is easier to stack while being stacked and transported. In addition, the pressure to the bucket body is gradually increased, so that under the same conditions, the bucket can be protected from damage to the maximum extent during a pressing process. The lid-pressing device of the invention is simple in structure and ingenious in conception. The device only needs to rotate the conveyor belt at runtime, and the rollers can press the lid without any power. Therefore, the running cost is reduced.

Owner:TIANJIN TONGLIN METAL PROD

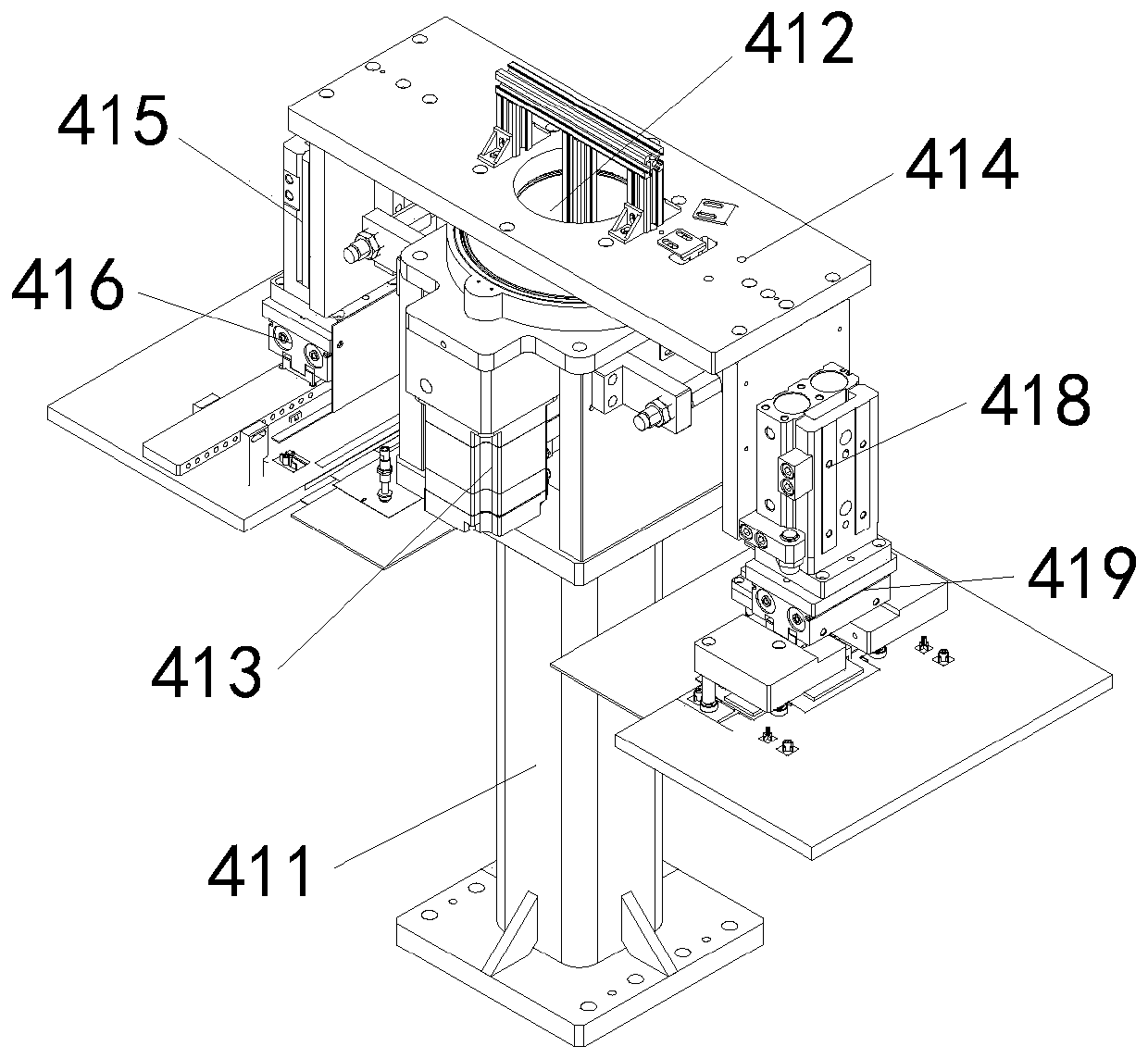

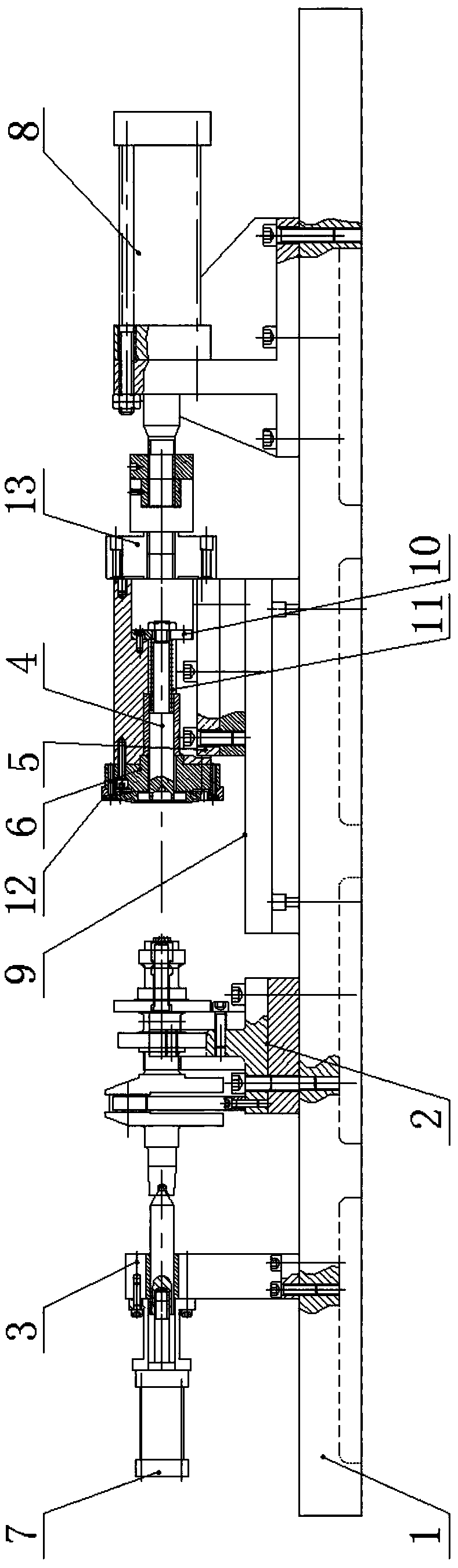

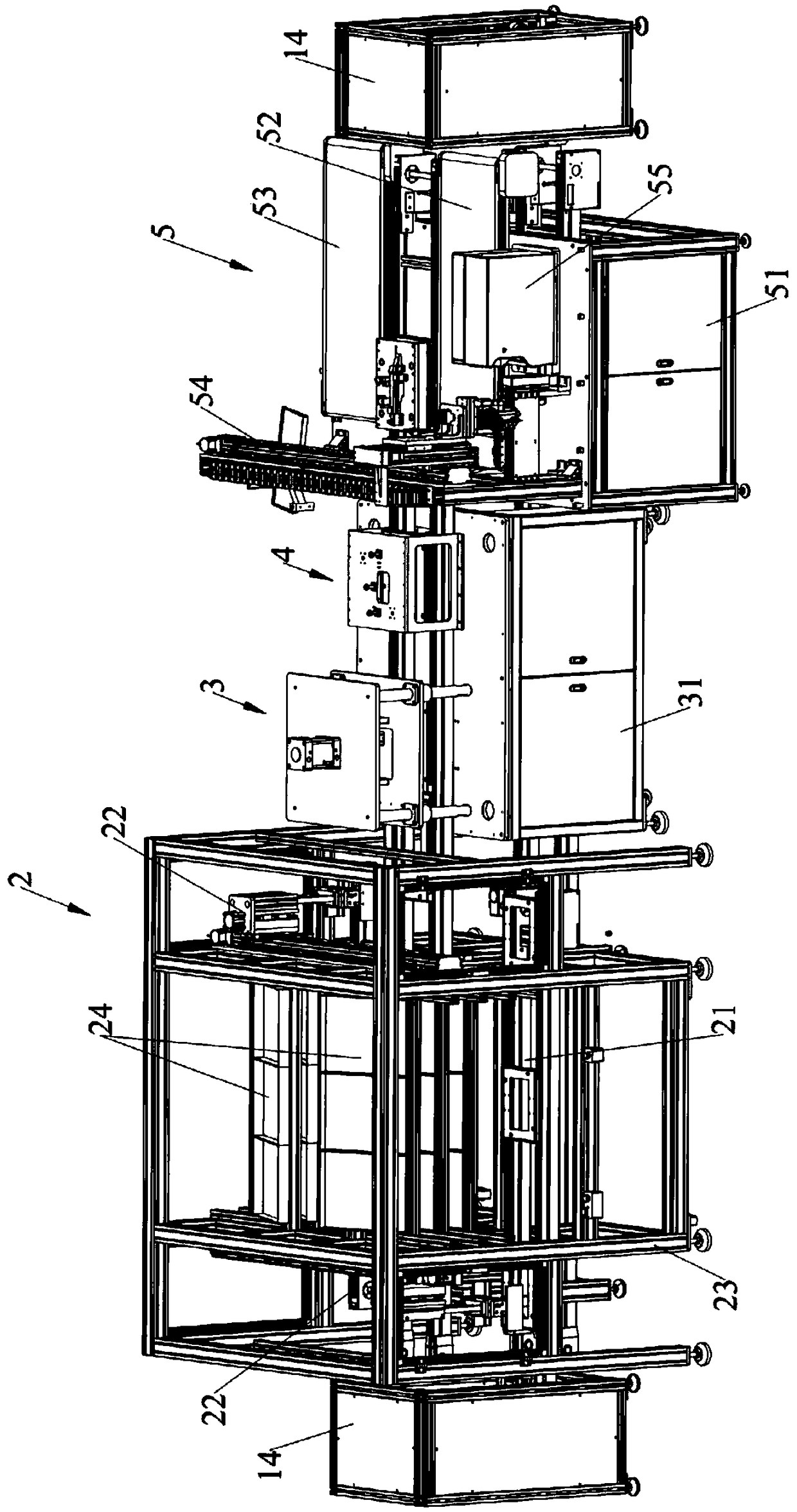

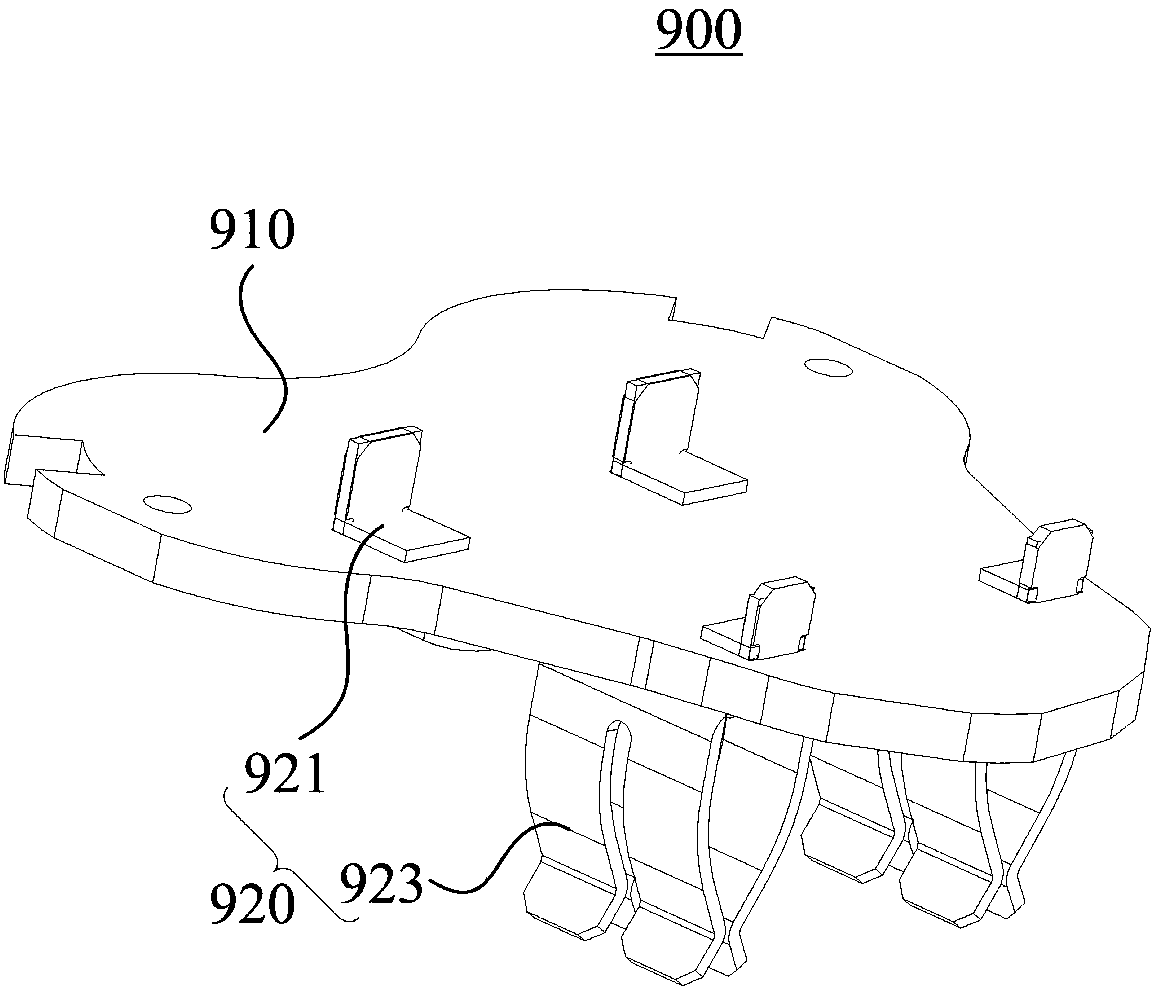

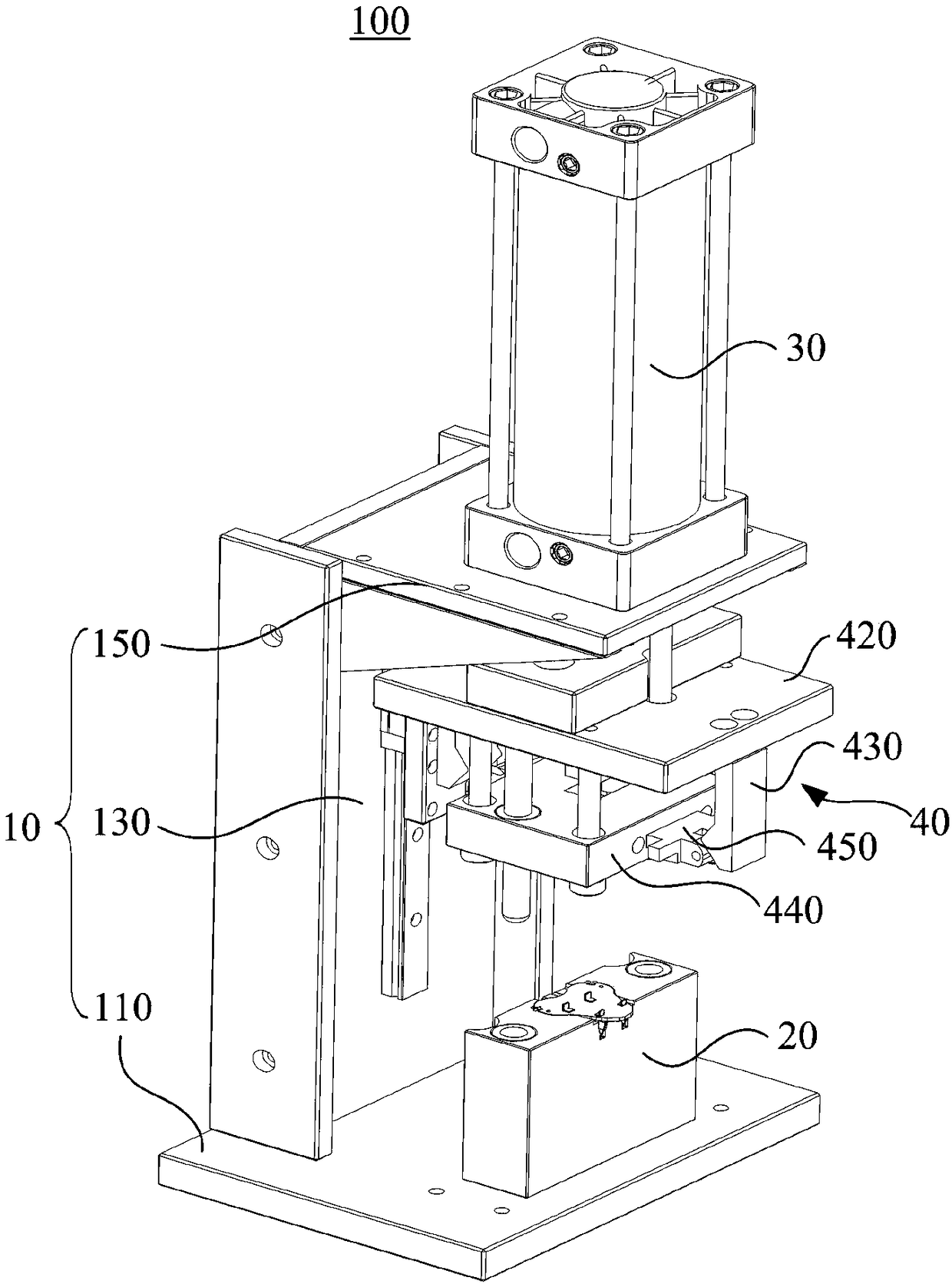

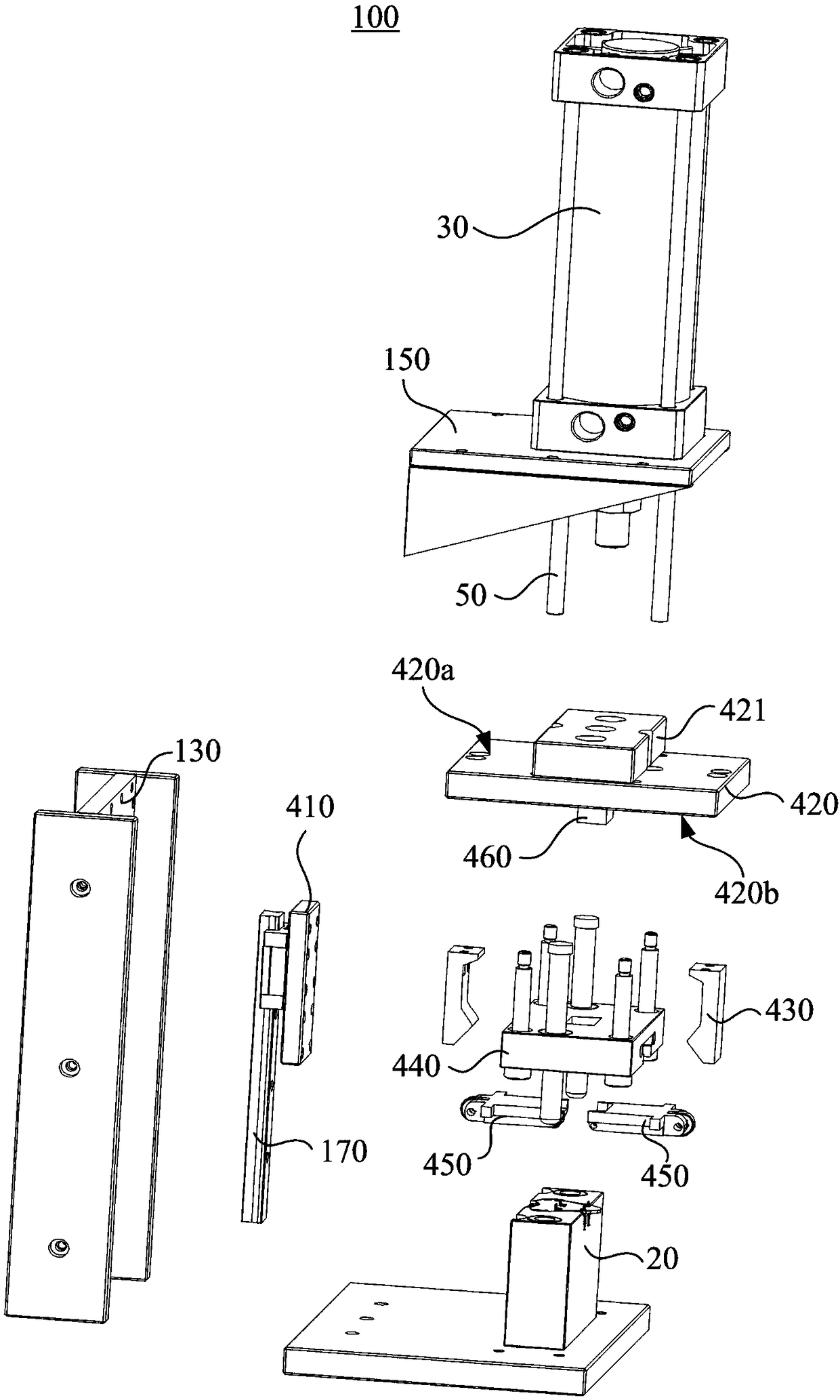

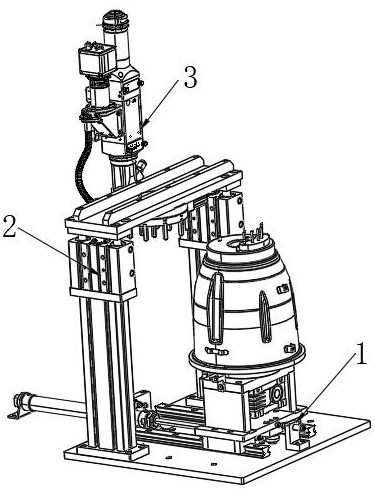

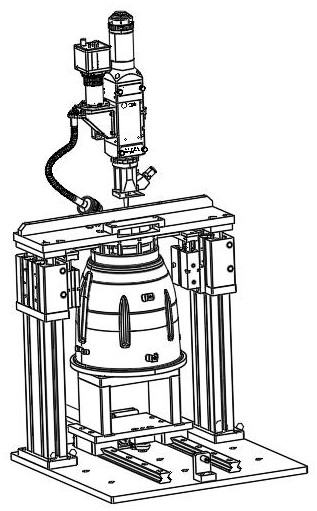

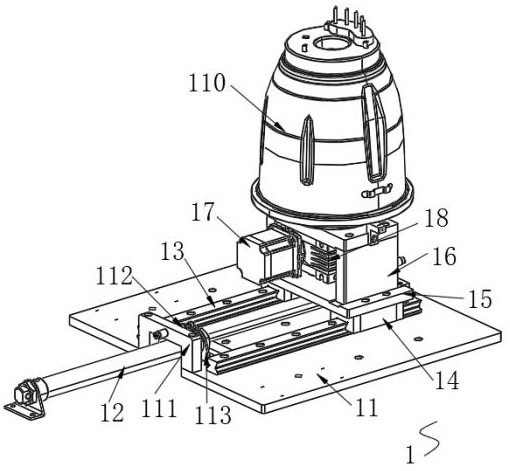

Rotating shaft, clamp spring and iron core integrated assembling device

The invention belongs to the technical field of machining equipment, and provides a rotating shaft, clamp spring and iron core integrated assembling device. A rotating shaft conveying mechanism is used for conveying a rotating shaft and then discharging the rotating shaft to the next station; a clamp spring conveying mechanism is used for conveying a clamp spring and discharging the clamp spring to the next station; a clamp spring press-fitting mechanism is used for receiving the rotating shaft and the clamp spring and press-fitting the rotating shaft to the clamp spring; and a rotating shaft iron core feeding mechanism comprises an iron core feeding assembly, a rotating shaft press-fitting assembly and an iron core discharging assembly, the iron core feeding assembly is used for conveying an iron core, and the rotating shaft press-fitting assembly is used for receiving the iron core conveyed by the iron core feeding assembly, press-fitting the rotating shaft to the iron core and then discharging the rotating shaft to the iron core discharging assembly for discharging. According to the rotating shaft, clamp spring and iron core integrated assembling device, each mechanism does not need manual operation, feeding, taking and press-fitting of materials can be completed, the labor cost can be saved, and the production efficiency is improved.

Owner:SHENZHEN JINMINJIANG RIVER MECHANICAL & ELECTRICAL EQUIP

Press-fit jig assembly and vacuum press-fit equipment

PendingCN112770514APressing to achieveAvoid deformationLaminating printed circuit boardsEngineeringMechanical engineering

The invention provides a press-fit jig assembly and vacuum press-fit equipment. The jig assembly comprises a jig cover plate, a jig bottom plate and a plurality of force-gathering press-fit convex blocks. A first step surface is arranged on the upper surface of the jig bottom plate, a bottom plate step surface is arranged on the upper surface of the jig bottom plate, the shape of the bottom plate step surface is matched with that of the first step surface, and when the workpiece to be pressed is arranged on the jig bottom plate in a sleeving mode, the upper surface of the jig bottom plate is attached to the first step surface of the workpiece to be pressed; a plurality of embedding holes penetrating through the upper surface and the lower surface of the jig cover plate are formed in the edge of the jig cover plate, the force gathering pressing protruding blocks are embedded in the embedding holes, and the maximum thickness of the force gathering pressing protruding blocks is larger than the length of the embedding holes; and the workpiece to be pressed is arranged on the jig bottom plate in a sleeving mode, and when the workpiece to be pressed is pressed by the jig cover plate and the jig bottom plate, the lower surface of the jig cover plate is pressed on the surface of the second step, and the force gathering pressing protruding block is pressed on the local surface of the edge of the workpiece to be pressed.

Owner:SHANGHAI LANGHUA SCI & TRADING

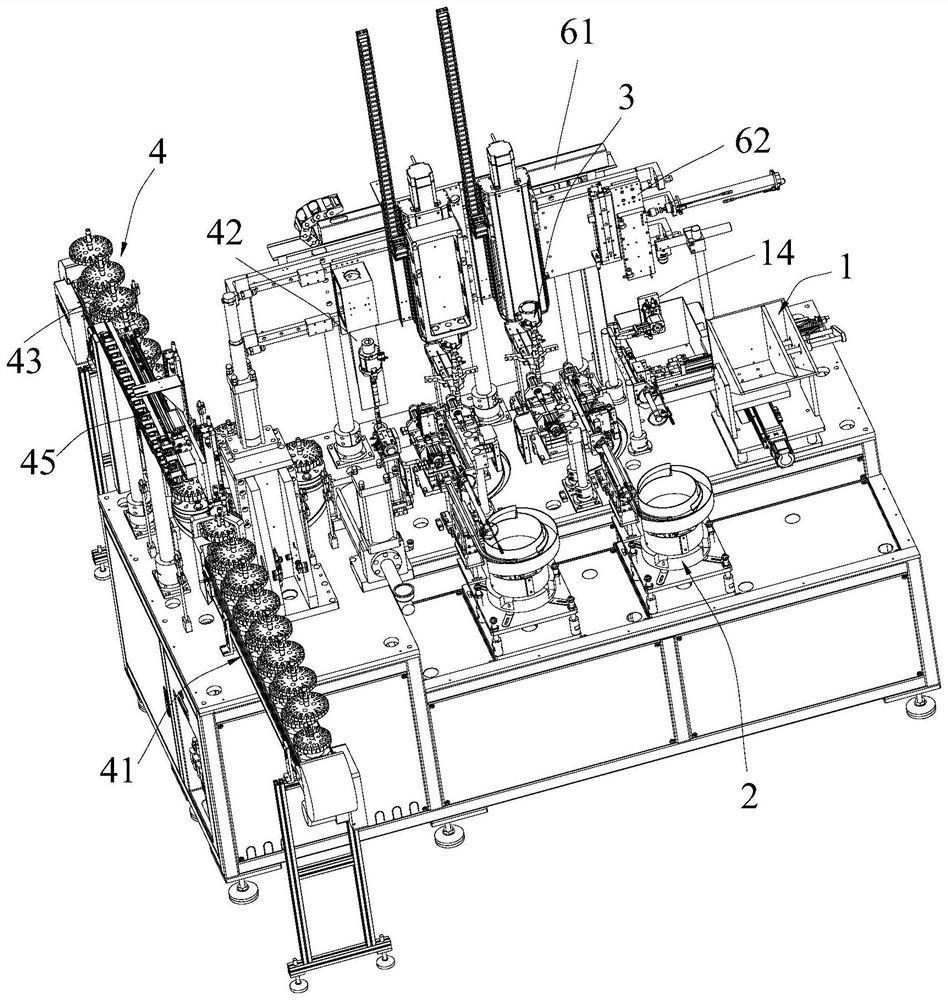

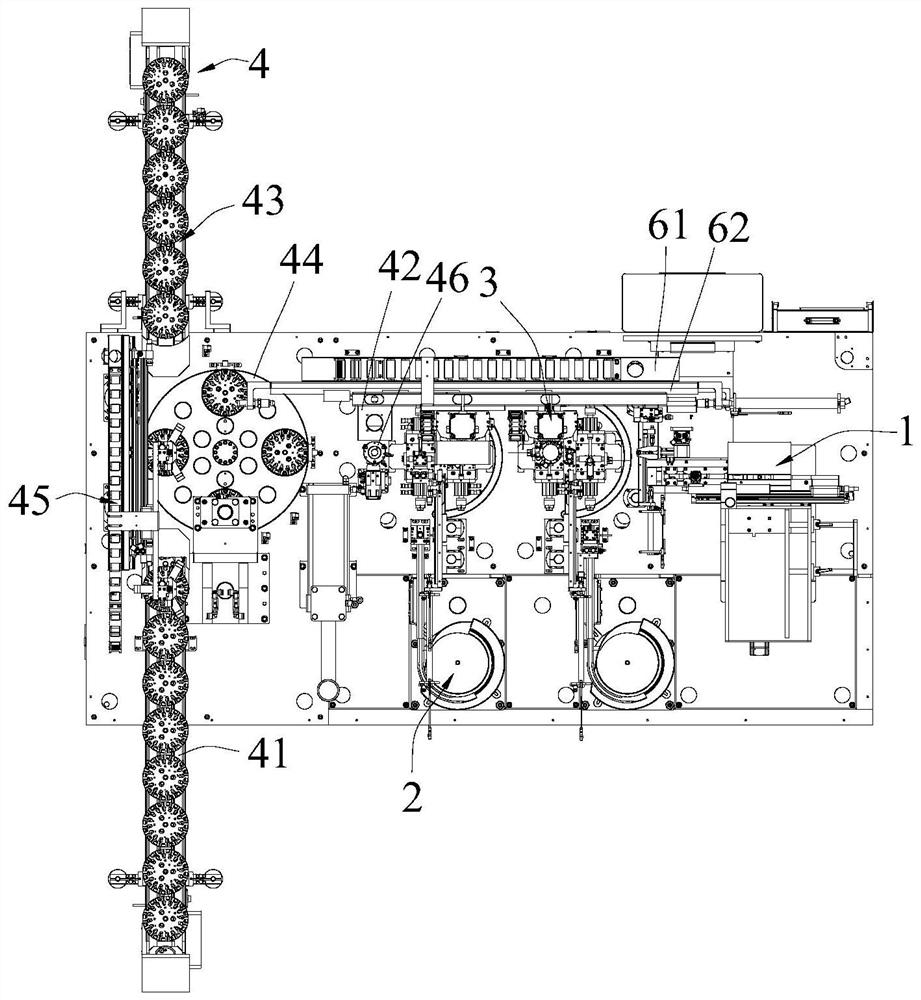

Pre-filling equipment for sterile solid medicine granules

ActiveCN112407429AIncrease contactImprove filling efficiencyPackaging automatic controlStopper feedingProcess engineeringAssembly line

The invention discloses pre-filling equipment for sterile solid medicine granules, and relates to the field of automatic equipment. The pre-filling equipment comprises a workbench, a feeding vibrationdisc, a medicine granule dispersing mechanism, a weighing mechanism, a rubber plug press-fitting mechanism and a bottle body press-fitting mechanism. The pre-filling equipment achieves automation inthe whole process based on assembly line type filling and automatic weighing; compared with traditional manual filling, the filling efficiency and the weighing precision are remarkably improved, and operation errors are reduced; and in the whole filling process, solid medicine granules can be in good contact with a pre-filling needle tube and are not prone to scattering.

Owner:WUHU SIMCERE ZHONGREN PHARM

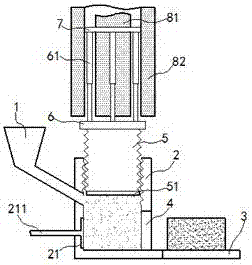

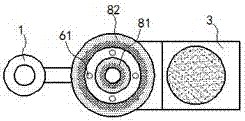

Electromagnetic briquetting machine

ActiveCN105584075BPressing to achieveExtended service lifePress ramRotary pressEngineeringConveyor belt

The invention relates to an electromagnetic briquetting machine, which includes a feeding end, a pressing bin and a conveyor belt; a discharge plate is installed on the side wall of the pressing bin facing the discharging end; A pressurizing screw is also installed on the top of the press-fitting chamber; a conductive sheet is fixedly installed on the upper end of the pressurizing thread, and conductive posts are rotationally symmetrically distributed on the conductive sheet; the upper ends of each of the conductive posts are fixed on the conductive ring; the conductive ring and the conductive sheet can rotate synchronously under the drive of the conductive column; the conductive sheet and the conductive ring are respectively connected to the positive and negative poles of the DC power supply; installed on the inner ring of the conductive ring There is an inner permanent magnet cylinder, and an outer permanent magnet cylinder is installed on the outer ring of the conductive ring; the opposite polarities of the inner permanent magnet cylinder and the outer permanent magnet cylinder attract each other; the briquetting machine is compact in structure, Small in size, it can press and pack chips efficiently, and is suitable for pressing and packing of various chips.

Owner:江苏百代节能建材有限公司

Electromagnetic briquetting machine

The invention relates to an electromagnetic briquetting machine. The electromagnetic briquetting machine comprises a feeding end, a press-fitting bin and a conveying belt. A discharging plate is arranged at the position, directly facing the discharging end, of the side wall of the press-fitting bin; a pressurizing screw rod is further arranged on the upper portion of the press-fitting bin, and a conducting strip is fixedly mounted at the upper end of the pressurizing screw rod; conducting columns are rotatably and symmetrically distributed on the conducting strip, and a conducting ring is fixed to the upper end of each conducting column; the conducting rings and the conducting strip can be driven by the conducting columns to synchronously rotate; the conducting strip is connected with the positive electrode and the negative electrode of a direct-current power source, and the conducting rings are connected with the positive electrode and the negative electrode of the direct-current power source; an inner permanent magnet cylinder is arranged on the inner rings of the conducting rings, and an outer permanent magnet cylinder is mounted on the outer rings of the conducting rings; and the opposite cylinder faces of the inner permanent magnet cylinder and the outer permanent magnet cylinder are in heteropole attraction. The electromagnetic briquetting machine is compact in structure, small and exquisite in size, capable of carrying out efficient press fitting on chippings and suitable for press fitting of multiple kinds of chippings.

Owner:江苏百代节能建材有限公司

Press fitting device special for transmission system leather cup sealing

InactiveCN110497178AGuaranteed to workPressing to achieveMetal working apparatusEngineeringMechanical engineering

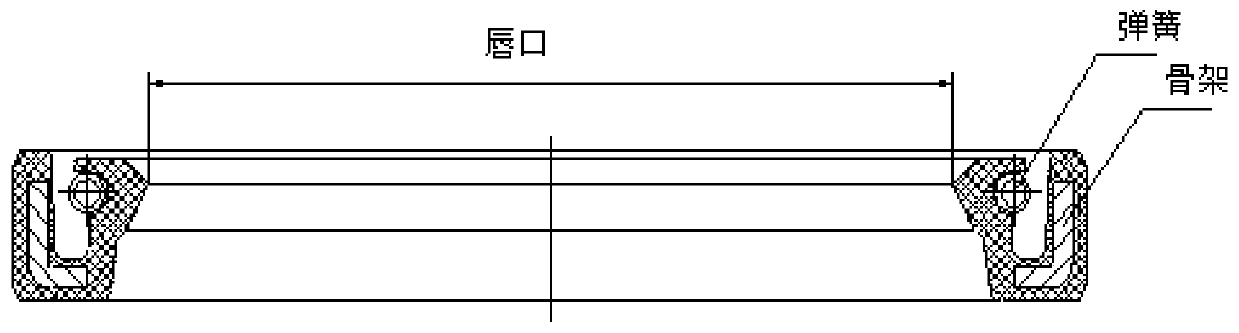

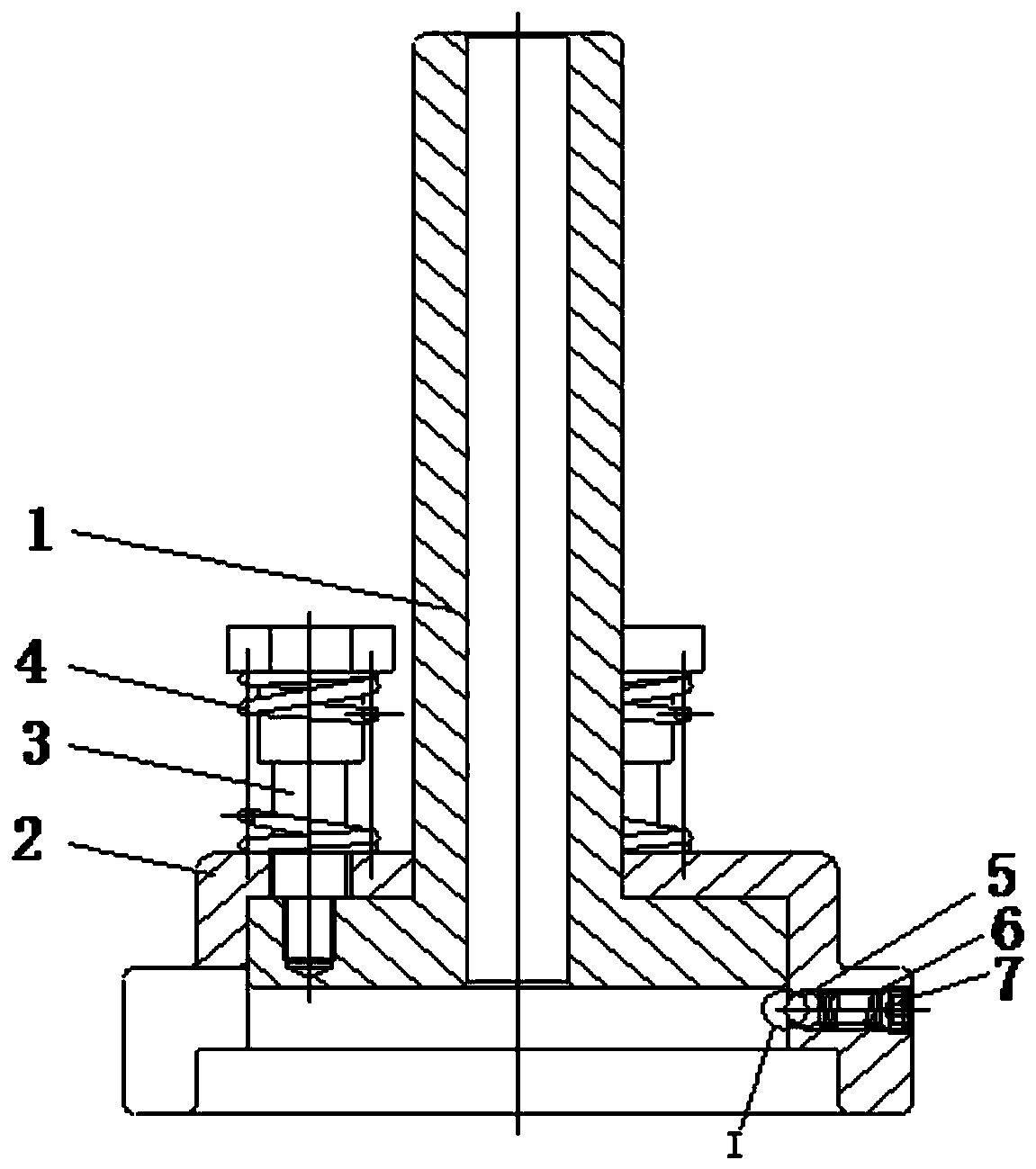

The invention belongs to the technical field of process toolings and particularly relates to a press fitting device special for transmission system leather cup sealing. The press fitting device special for sealing comprises a pressure head, a shell, and a positioning mechanism and a limit mechanism which are mounted on the shell. The press fitting device is provided with the positioning mechanismand the limit mechanism, leather cup limit press fitting can be achieved, it is guaranteed that a leather cup is concentric with a mounting base after press abutting and press fitting, a leather cup leakage fault caused by improper press fitting is avoided, and normal working of a transmission system is guaranteed.

Owner:HARBIN DONGAN ENGINE GRP

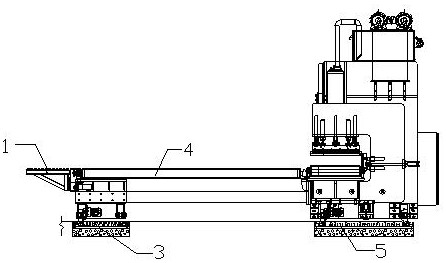

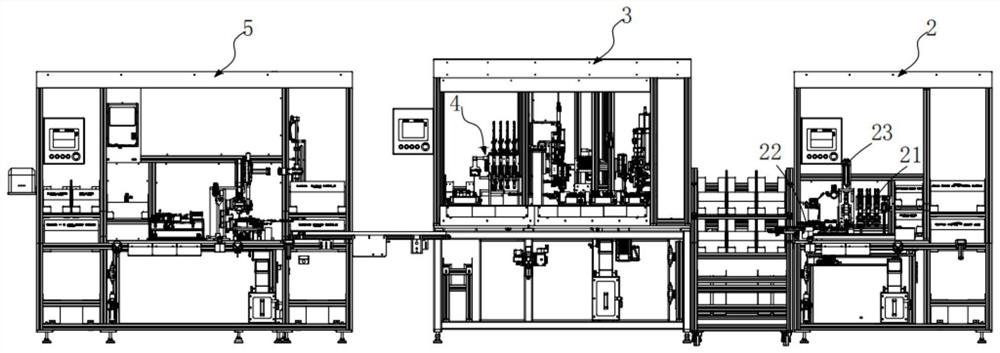

Fuse box press-mounting and testing machine

PendingCN109031032APressing to achieveImplement automated testingFuses testingEngineeringMechanical engineering

The present invention discloses a fuse box press-mounting and testing machine, pertaining to the technical field of fuse box press-mounting and testing. The fuse box press-mounting and testing machinecomprises a carrier circulation line. The carrier circulation line is slidably provided with carriers used for transporting fuse boxes. The machine, along the feeding direction of the carrier circulation line, is successively provided with a pre-mounting mechanism, wherein the pre-mounting mechanism comprises a pre-mounting conveying line parallelly arranged with the carrier circulation line andtwo load transferring components, the first load transferring component transfers the fuse boxes on the carrier circulation line to the pre-mounting conveying line, and after the fuse boxes are mounted into various components, the second load transferring component re-transfers the fuse boxes to the carrier circulation line to continue conveying; a press-mounting mechanism capable of pressing downwardly towards the carrier circulation line; a testing mechanism, wherein the testing mechanism comprises multiple probes used for testing all the components separately; and a sorting mechanism, wherein the sorting mechanism comprises a qualified product conveying line and an unqualified product conveying line parallelly arranged with the carrier circulation line. The machine can realize the press-mounting, the automatic testing and the automatic sorting of the fuse boxes, and the press-mounting efficiency and the press-mounting accuracy of the fuse boxes are improved.

Owner:昆山泽旭自动化科技有限公司

Elastic piece laminating device

InactiveCN108500592AFully pressedPressing to achieveMetal working apparatusCamMechanical engineering

The invention relates to an elastic piece laminating device. The elastic piece laminating device comprises a base, a fixing piece, a driving piece and a laminating assembly, the fixing piece and the driving piece are fixed to base, and the laminating assembly is in transmission connection with the driving piece; the laminating assembly comprises a driving plate, a pushing piece, a laminating base,a first laminating piece, an elastic piece and a second laminating piece, the pushing piece is provided with at least one cam block, and the cam block is provided with an upward-moving section and adownward-moving section; the driving plate can move relative to the laminating base, and in the moving process of the driving plate relative to the laminating base, the upward-moving section and the downward-moving section abut against the first laminating piece successively; and when the upward-moving section abuts against the first laminating piece, the first laminating piece moves relative to the laminating base and laminates an elastic piece, when the downward-moving section abuts against the first laminating piece, the first laminating piece gradually resets under action of the elastic piece, when the first laminating piece slides through the last cam block, the second laminating piece penetrates through a through hole in the laminating base and laminates the elastic piece again, andthe elastic piece laminating device can achieve full laminating of the elastic piece.

Owner:广东贝仕达克科技有限公司

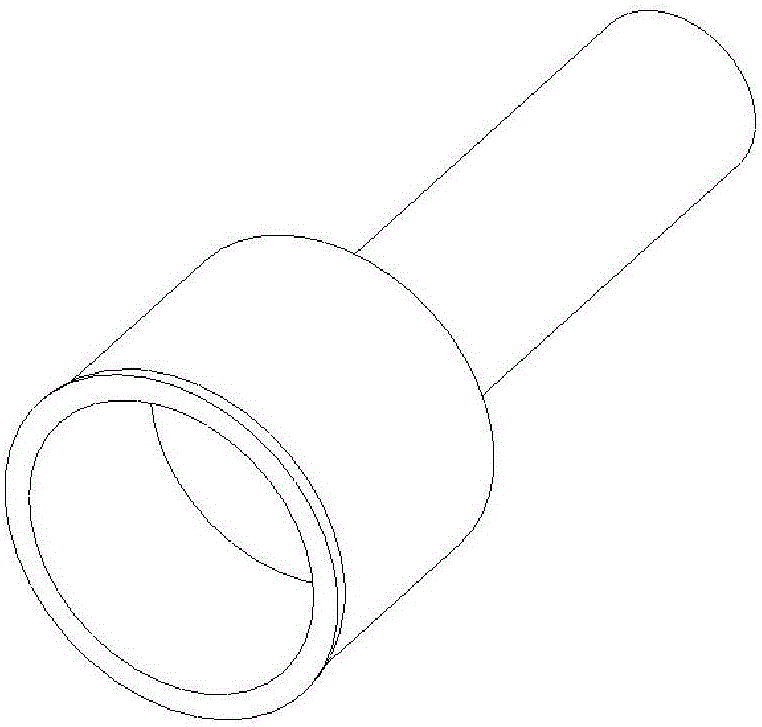

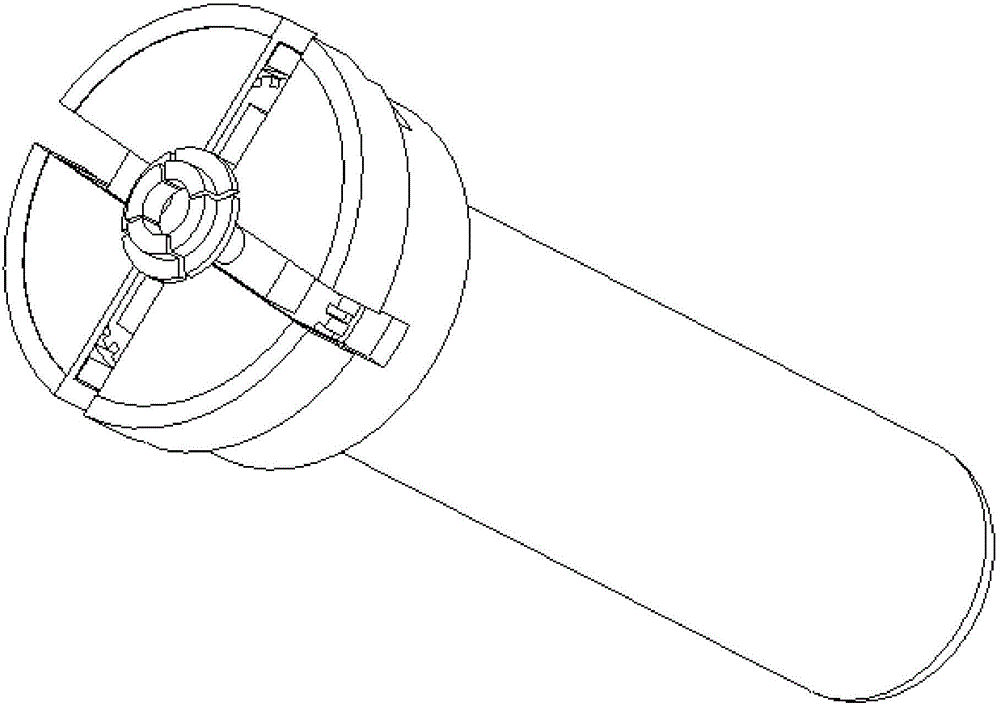

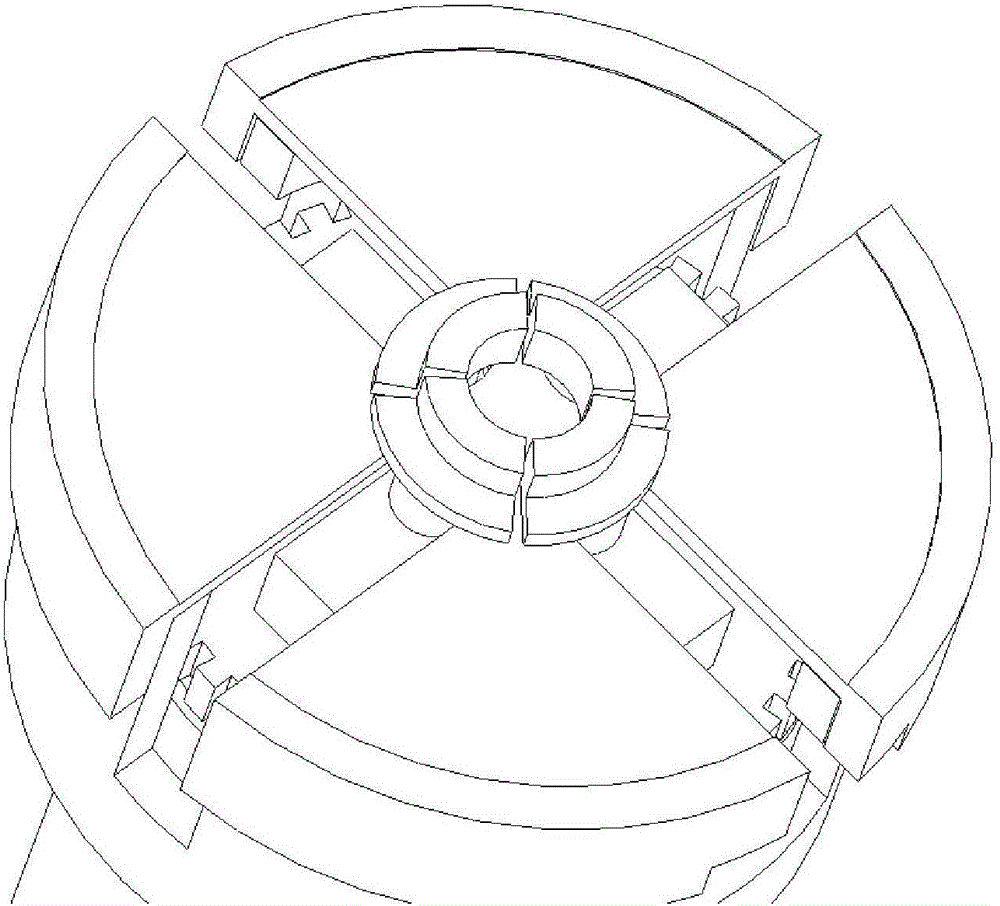

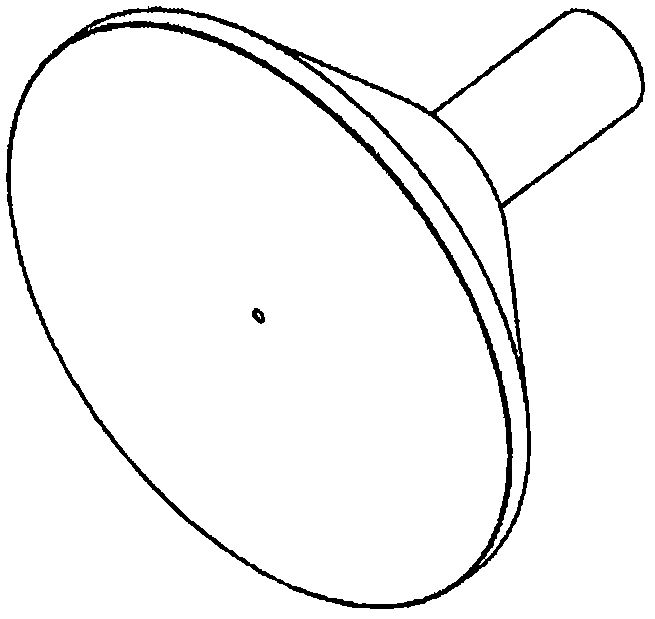

Installing tool for rear oil seal of crankshaft

ActiveCN105150164AImprove versatilityPressing to achieveMetal-working hand toolsCrankshaftPetroleum engineering

The invention discloses an installing tool for a rear oil seal of a crankshaft. The installing tool comprises a body, a driving disk rotationally installed on the body, a guiding disk installed on the body and a plurality of oil seal acting blocks installed on the guiding disk in a sliding manner. The end face of the driving disk is provided with spiral teeth. The oil seal acting blocks are provided with tooth faces opposite to the spiral teeth. The tooth faces are provided with driving teeth meshed with the spiral teeth. The oil seal acting blocks have sliding strokes during which the oil seal acting blocks get close to or away from one another under the action of cooperation of the driving teeth and the spiral teeth. According to the installing tool, the positions of the oil seal acting blocks on the guiding disk are adjusted through the spiral teeth, and therefore the installing tool is suitable for rear oil seals in different sizes. Thus, the universality of the installing tool is better.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Automatic rotating laser welding mechanism for electric kettle base

PendingCN113210866AReduce labor costsReduce time consumptionWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryEngineering

The invention discloses an automatic rotating laser welding mechanism for an electric kettle base, and relates to the technical field of electric kettle processing equipment. The telescopic end of a pushing air cylinder is connected with a support plate through a connecting plate; a motor and a speed reducer are fixedly installed in a first placing frame separately, and the output end of the speed reducer is fixedly connected with a rotating seat; the telescopic ends of a first pressing air cylinder and a second pressing air cylinder are jointly and fixedly connected with a tooling plate; and the interior of a pressing block is rotationally connected with a rotating disk. The equipment is novel in structure, low in cost input and convenient to maintain, feeding and positioning are integrated, time and labor are saved, the labor cost is reduced, and the processing efficiency is improved; a workpiece can be pressed and positioned, so that the problem that the workpiece deviates in the welding process is solved, and the welding accuracy and uniformity are improved; and an inner ring and an outer ring of the workpiece can be welded through a first welding hole, a second welding hole and a third welding hole, so that the product quality is further improved.

Owner:广东德益激光科技股份有限公司

Segmented wide rubber pressing and molding machine

The invention discloses a segmented wide rubber pressing and molding machine. The segmented wide rubber pressing and molding machine includes a main track, a slave track, a main drive mechanism, and apressing base; the main track and the slave track are parallel to each other; the main drive mechanism is arranged on the main track and can reciprocate along the length direction of the main track;the pressing base is arranged on the slave track, and the main drive mechanism and the pressing base are connected by a connecting mechanism; the middle of the pressing base is provided with a hot pressing bonding mechanism, two clamping mechanisms and two traction mechanisms; the clamping mechanisms are separately located at the feeding port and discharging port of the hot pressing bonding mechanism, and the traction mechanisms are separately located at the feeding port and discharging port of the clamping mechanisms; each clamping mechanism includes an upper clamping part and a lower clamping part, and both the upper clamping part and the lower clamping part can reciprocate in the vertical direction; and the hot pressing bonding mechanism can heat and press the wide rubber. The segmentedwide rubber pressing and molding machine has the advantages of small volume and low cost.

Owner:磐石油压工业(安徽)有限公司

Pressing and ironing mechanism for garment production

The invention relates to the technical field of garment pressing and ironing, in particular to a pressing and ironing mechanism for garment production. The pressing and ironing mechanism comprises anelectric cylinder, a rack, a heat insulation plate, a heating plate, a gear, a driving wheel, anti-scalding cloth and an open groove, wherein the rack is driven by the electric cylinder to move downwards, and therefore the heat insulation plate and the heating plate are driven to move downwards relative to a hollow box, meanwhile, the gear and the driving wheel are driven to rotate, the driving wheel rotates to drive the anti-scalding cloth to rotate, when the open groove is changed along with the rotation position of the anti-scalding cloth and the heating plate moves downwards to the bottomend face to be aligned with the anti-scalding cloth, the open groove is rotated to the lower end of the heating plate, and the heating plate continues to move downwards to penetrate through the open groove and be attached to the clothes, so that garment are pressed and ironed, after the garment are pressed and ironed, the rack is driven by the electric cylinder to move upwards, the open groove ismoved away from the lower portion of the heating plate, at the moment, the portion, without the open groove, of the anti-scalding cloth is located on the lower portion of the heating plate, the heating plate is shielded, and the use safety is improved.

Owner:安徽复盛时装有限公司

Servo driven pressing device

ActiveCN110216182BPressing to achieveMeet different location requirementsMetal working apparatusControl systemBall screw

The invention provides a servo drive laminating device, which solves the problem of the power source of a special laminating machine during the laminating process; the device comprises an installationbase, a servo motor, a bidirectional ball screw nut pair, two cam sliding blocks driven by the bidirectional ball screw nut pair, a sliding block, a weighing sensor, an external reference limiting block, an internal reference limiting block, a joint injection oil cup, a longitudinal guide mechanism composed of a V-shaped convex guide rod and a V-shaped concave guide plate, a collision block, a stroke switch, a shaft, a support type roller, a straight-through injection oil cup, etc., the device can realize the different position requirements of the upward movement of a concave mold according to the product laminating process requirement, so multiple flanging can be finished and the laminating is realized; the weighing sensor feeds back the condition of the laminating force at different positions of the control system in real time.

Owner:CHINA FIRST AUTOMOBILE +1

Assembly and processing line and assembly process of left gear lever handle for automobile steering wheel

ActiveCN112222825BReduce manual operationsImprove assembly accuracyAssembly machinesSteering wheelAssembly line

The invention relates to the technical field of automobile steering wheel assembly, in particular to an assembly processing line and an assembly process for a left gear lever handle for an automobile steering wheel. The pre-assembly assembly, rotary assembly assembly, adsorption press-fit assembly and lock-press assembly arranged in sequence, through the pre-assembly assembly, rotation assembly assembly, adsorption press-fit assembly and lock-press assembly Combined use enables automatic assembly of the processed parts in each assembly step, reduces manual operations, improves assembly accuracy and assembly quality, and solves the technical problem of low assembly accuracy caused by artificial factors in the assembly process , effectively reducing the defective rate.

Owner:浙江金麦特自动化系统有限公司

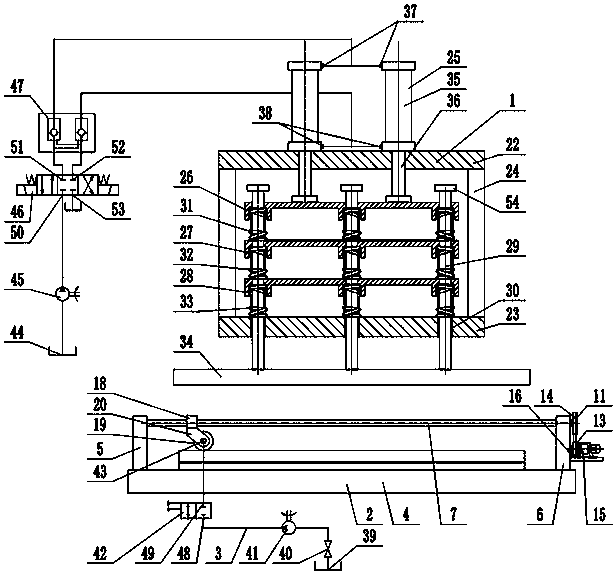

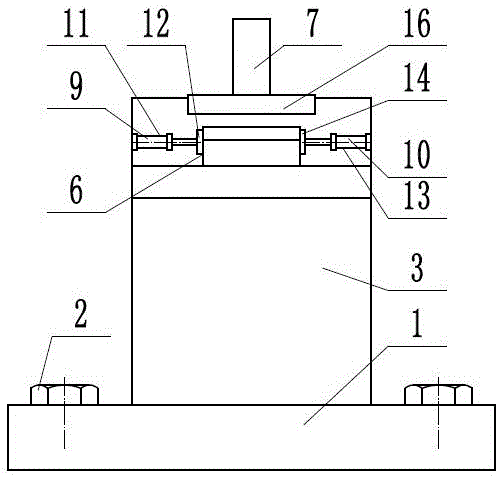

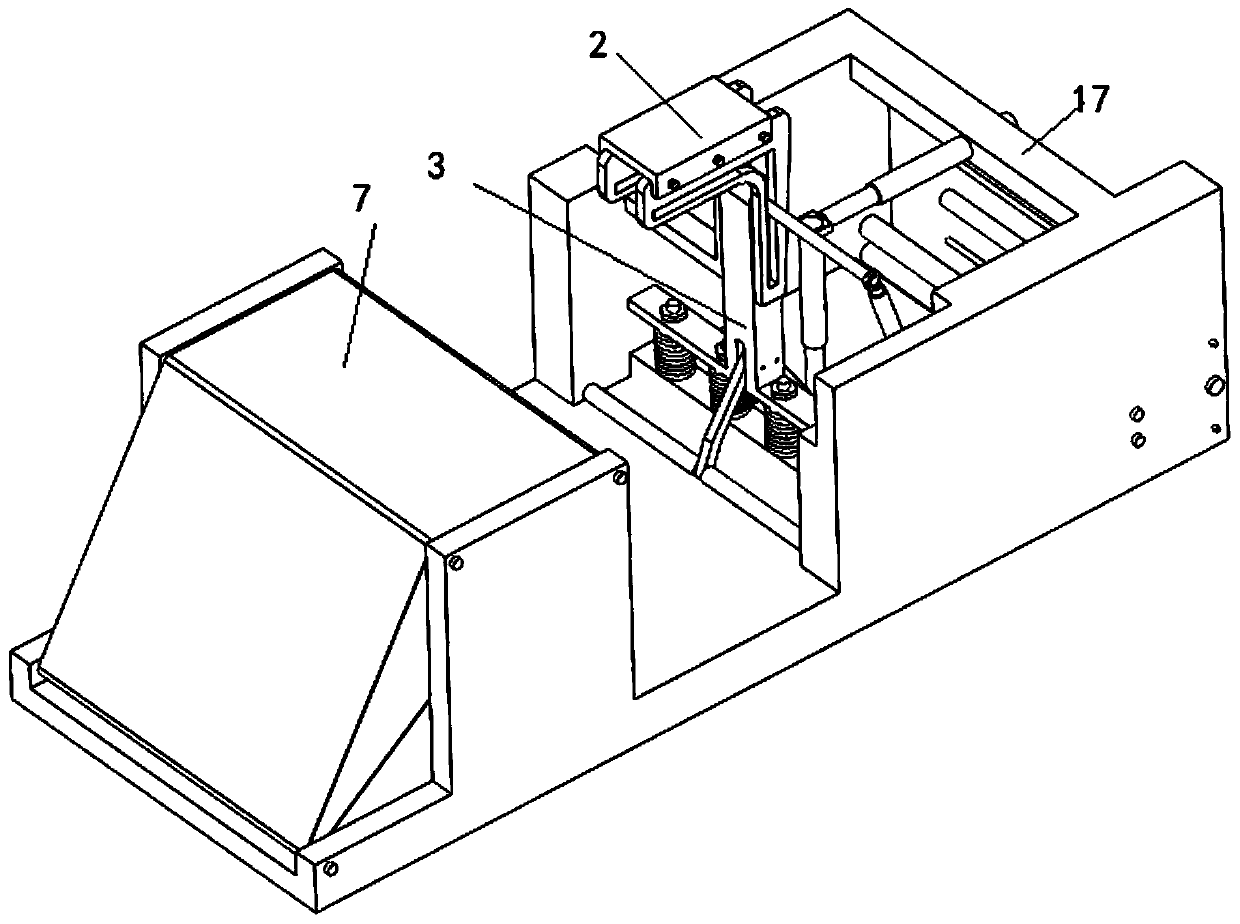

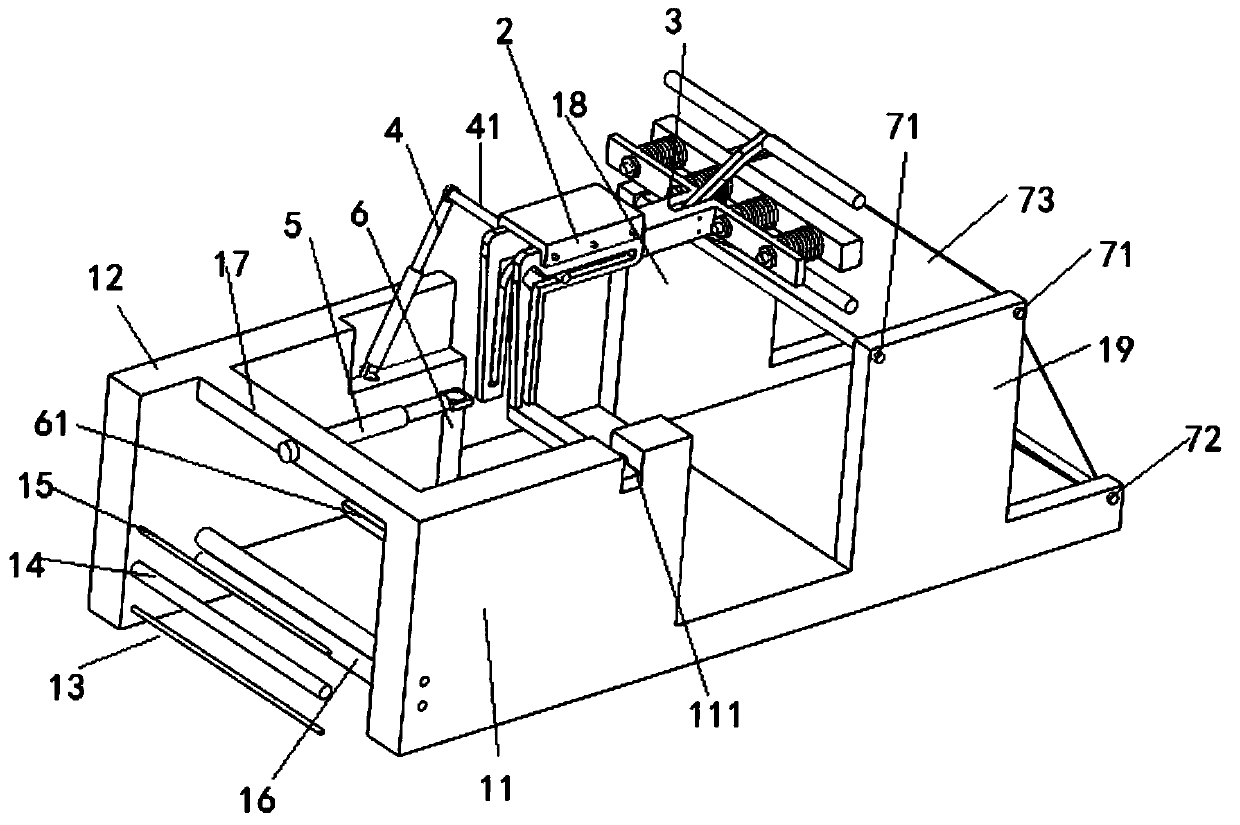

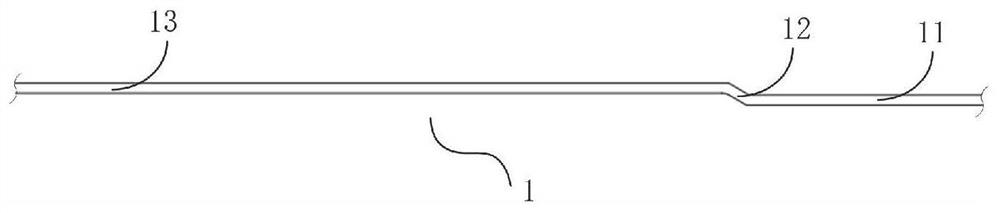

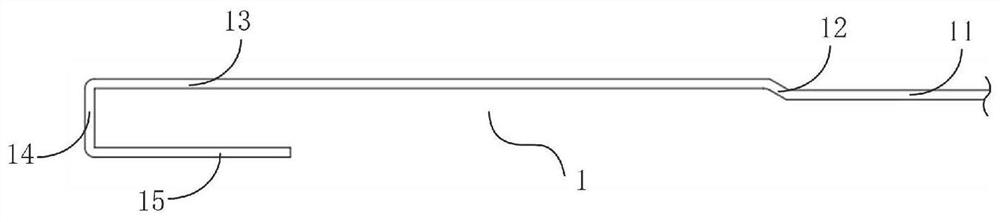

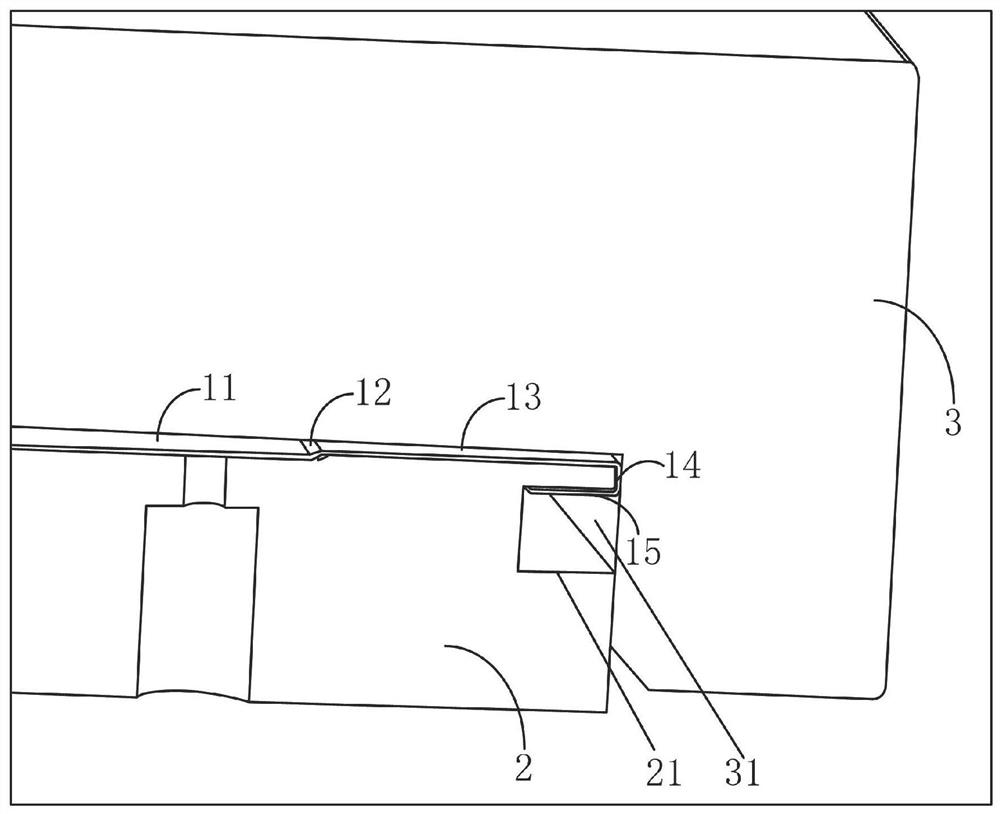

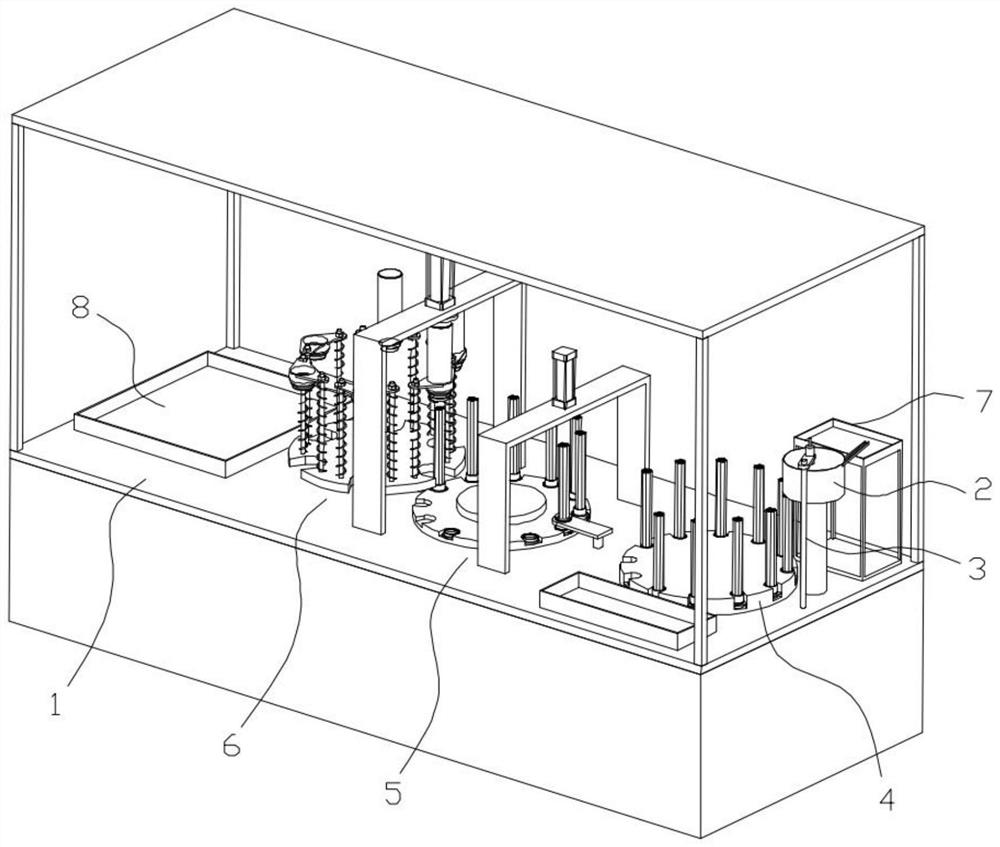

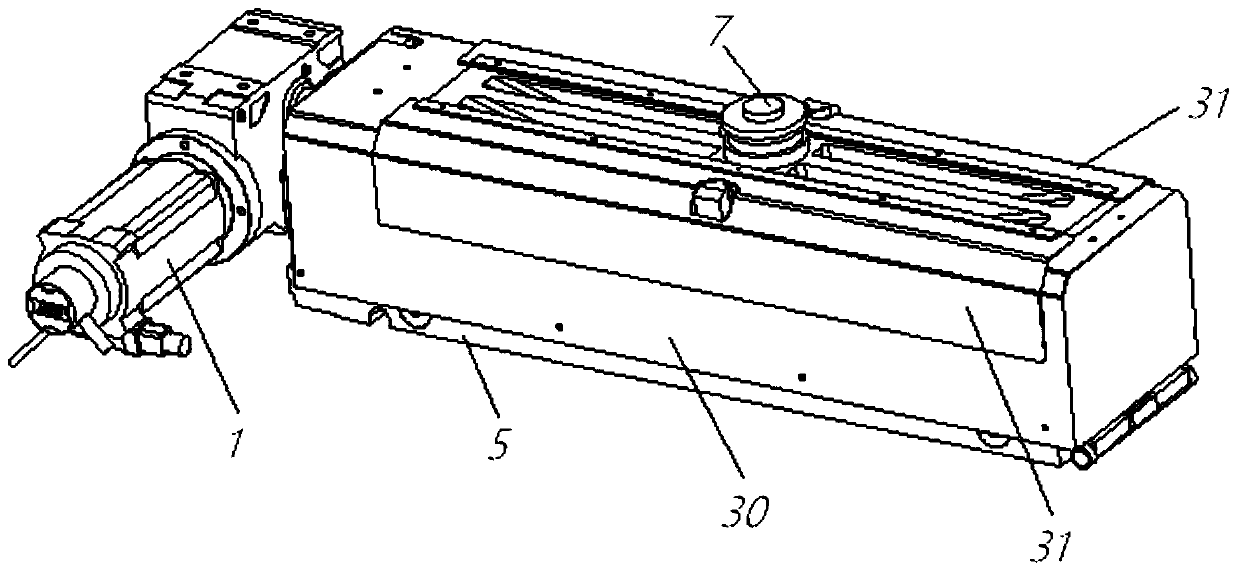

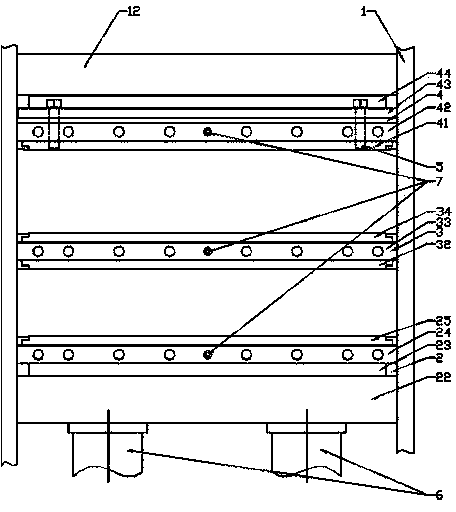

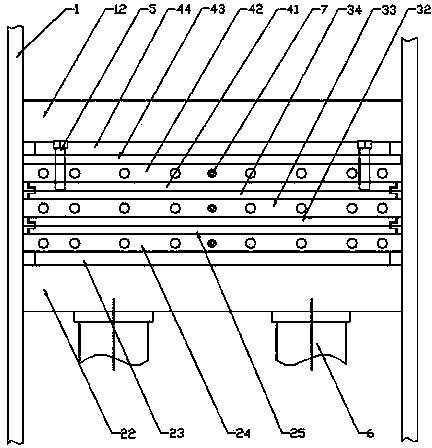

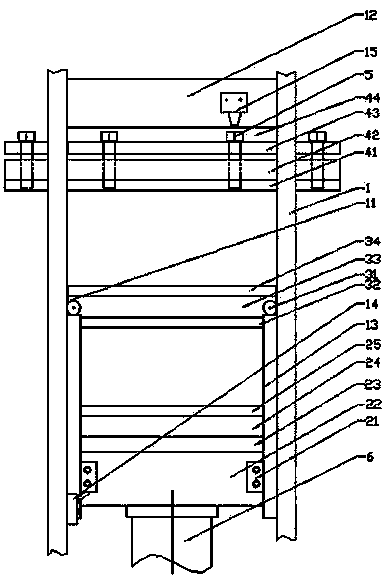

Flexible circuit board pressing device and rapid pressing machine

ActiveCN102166874BIncrease the bearing areaStable pushLaminationLamination apparatusHydraulic cylinderFlexible circuits

The invention discloses a flexible circuit board pressing device and a rapid pressing machine comprising the same, and aims at providing a flexible circuit board pressing device with stable motion and higher precision and a fully-automatic rapid pressing machine with high production rate. The flexible circuit board pressing device comprises a stand (1), a lower pressing plate (2), at least one middle plate (3) and an upper pressing plate (4), wherein guide sliding blocks are arranged on the lower pressing plate (2), the lower part of the inner wall of the stand (1) is provided with guide rails, the guide sliding block is in sliding fit with the guide rail, and two hydraulic cylinders (6) are connected to the lower pressing plate (2). The rapid pressing machine further comprises a hydraulic device except the flexible circuit board pressing device, wherein the hydraulic cylinders (6) are connected with the lower pressing plate (2). The invention can be widely applied to the processing field of flexible circuit boards.

Owner:珠海比昂电子设备有限公司

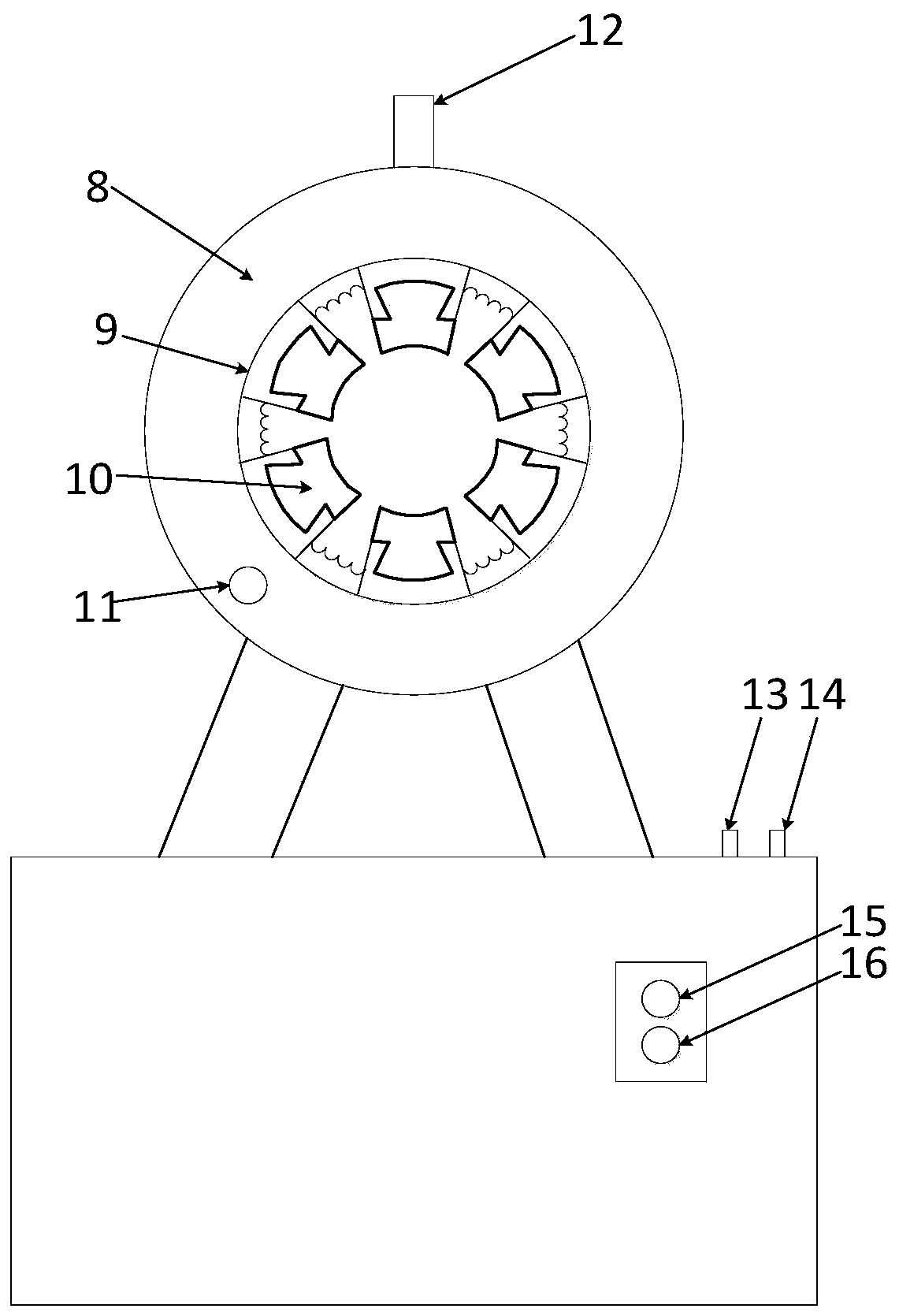

A high-voltage and high-current coaxial cable joint pressing device

ActiveCN108418147BPressing to achieveEasy to controlLine/current collector detailsApparatus for joining/termination cablesPower flowCoaxial cable

The invention discloses a high-voltage and high-current coaxial cable joint press-fit device, which comprises a hydraulic energy mechanism and a press-fit mechanism. The hydraulic energy mechanism andthe press-fit mechanism are separately arranged. The energy of the hydraulic energy mechanism is supplied to the press-fit mechanism. The hydraulic energy mechanism comprises a fixed pressure head (9) and movable pressure heads (10). The fixed pressure head (9) is coupled to a piston rod on an oil cylinder (8). An electromagnetic reversing valve is arranged at the connection part of the piston rod and the oil cylinder (8). The fixed pressure head (9) comprises a plurality of identical sector-shaped connecting members. A sector-shaped groove is arranged at one side of a small arc side of eachsector-shaped connecting member. The number of movable pressure heads (10) is several. Each movable pressure head has a sector-shaped protrusion at one end and a sector-shaped structure at the other end, and the sector-shaped protrusion is snap-fitted with the sector-shaped groove. The inner sides of the sector-shaped structures of the several movable pressure heads constitute a press-fit inner circle. The high-voltage and high-current coaxial cable joint press-fit device of the invention realizes accurate press fitting.

Owner:NAVAL UNIV OF ENG PLA

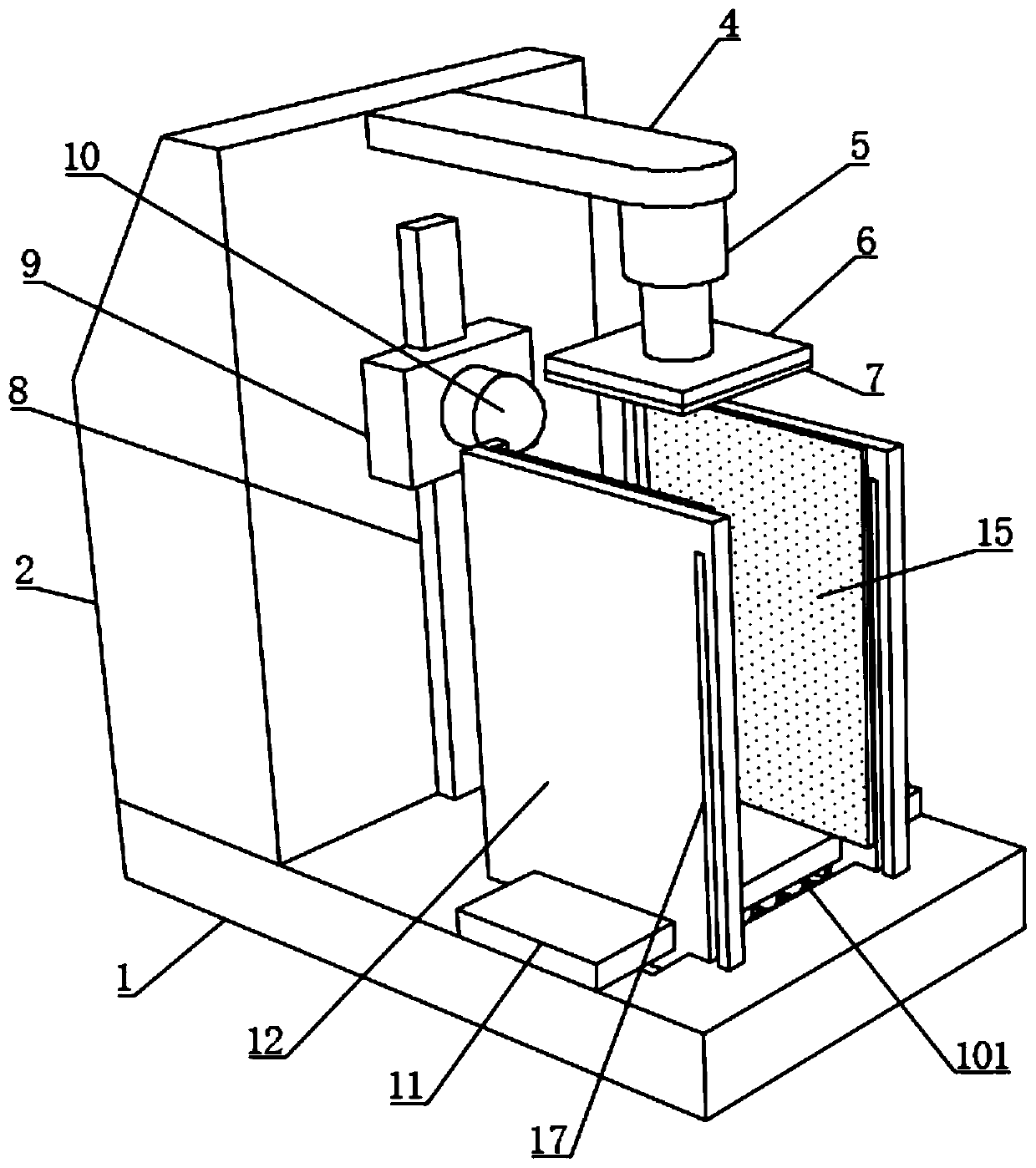

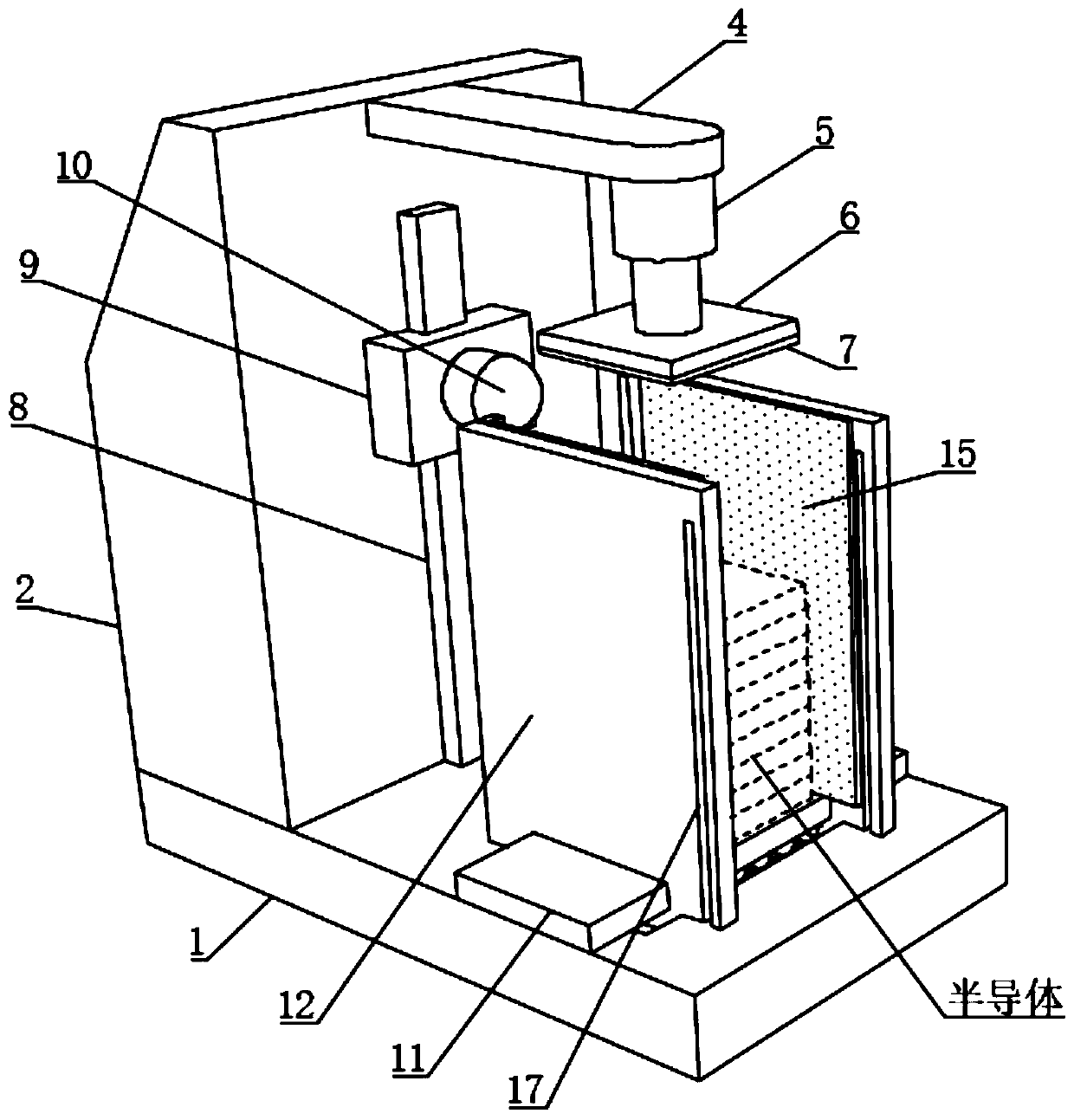

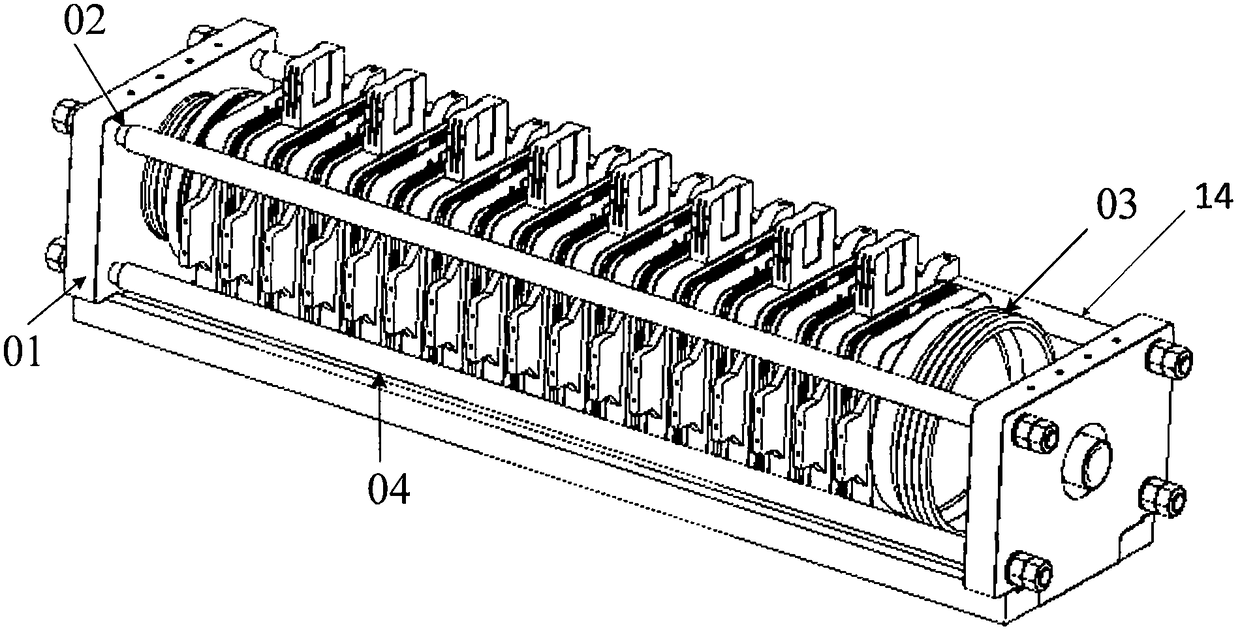

A large component igbt press-fit unit

ActiveCN105355603BImprove applicabilityEvenly dispersedSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

A large-component IGBT press fitting unit, comprising a support frame (14) and a press fitting unit that is located in the support frame (14) and is used for fixing an IGBT valve series. The press fitting unit comprises: press fitting stress cones (11) located at the two ends of the IGBT valve series, a pressure adaptive adjusting mechanism and an insulated isolation structure; and the press fitting stress cones (11) and the pressure adaptive adjusting mechanism are respectively and fixedly connected to metal end plates (01) arranged at the two ends of the support frame (14), and the insulated isolation structure is used for realizing electric isolation of the press fitting structure from electrical components.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Laminated tempered glass processing technology

PendingCN114834135AQuality improvementIncrease productivityLamination ancillary operationsLaminationLaminated glassToughened glass

The invention relates to a laminated tempered glass processing technology which comprises the following steps: step 1, cutting and blanking glass, and edging and cleaning the cut glass; 2, feeding the cleaned glass into a toughening furnace for toughening treatment; step 3, laminating, laying the PVB film on the bottom layer glass, and then covering the PVB film with the upper layer glass; step 4, feeding the laminated glass into a roller press; 5, the extruded laminated glass is fed into a high-pressure kettle to be subjected to sectional type heating and pressurizing treatment; according to the invention, the press-fit assembly is arranged in the press-fit mechanism, and a horizontal pushing process is added in the vertical press-fit process, so that bubbles existing between two pieces of glass can be effectively pushed out, bubbles do not exist between the two pieces of glass which are adhered together through an intermediate film, the quality of finished products can be greatly improved, and the production efficiency is improved. The production efficiency is improved.

Owner:吕娟伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com