Servo driven pressing device

A pressing device, servo-driven technology, applied in metal processing equipment, metal processing, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

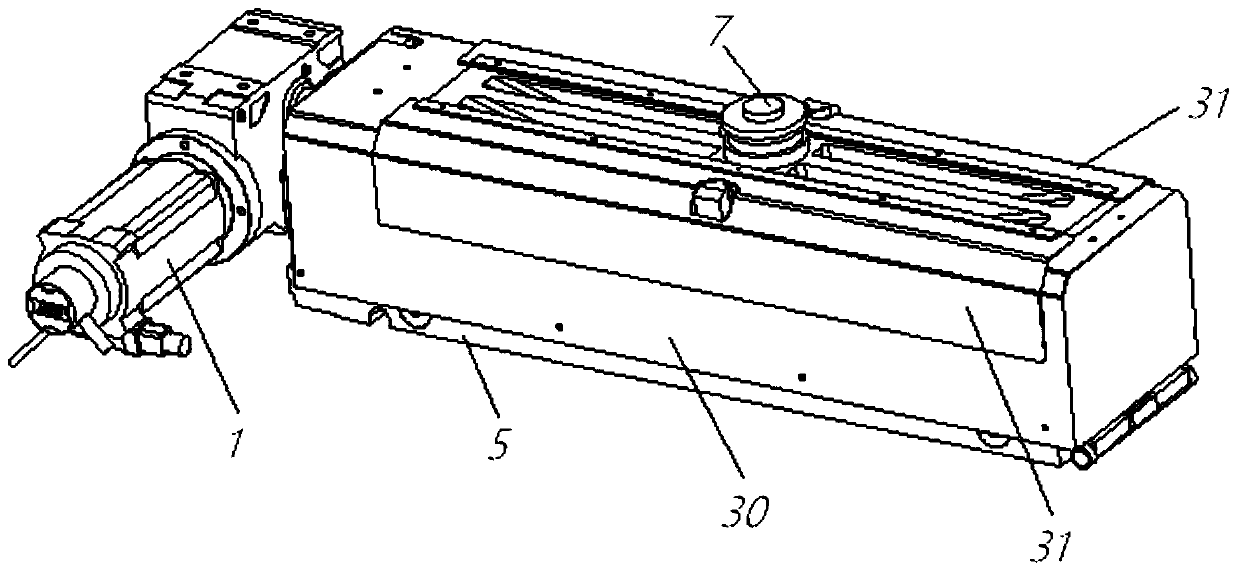

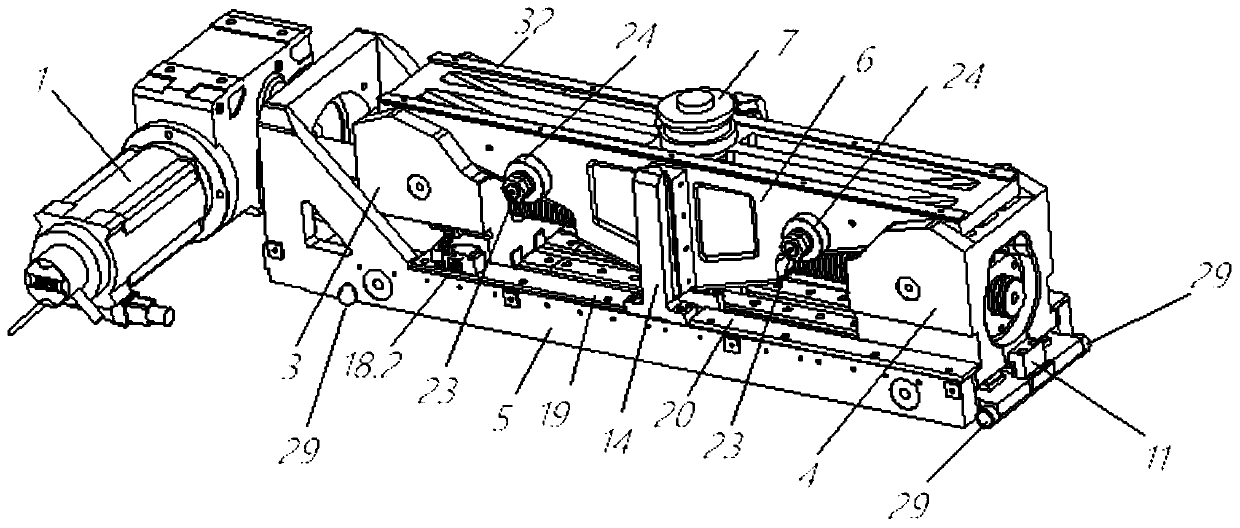

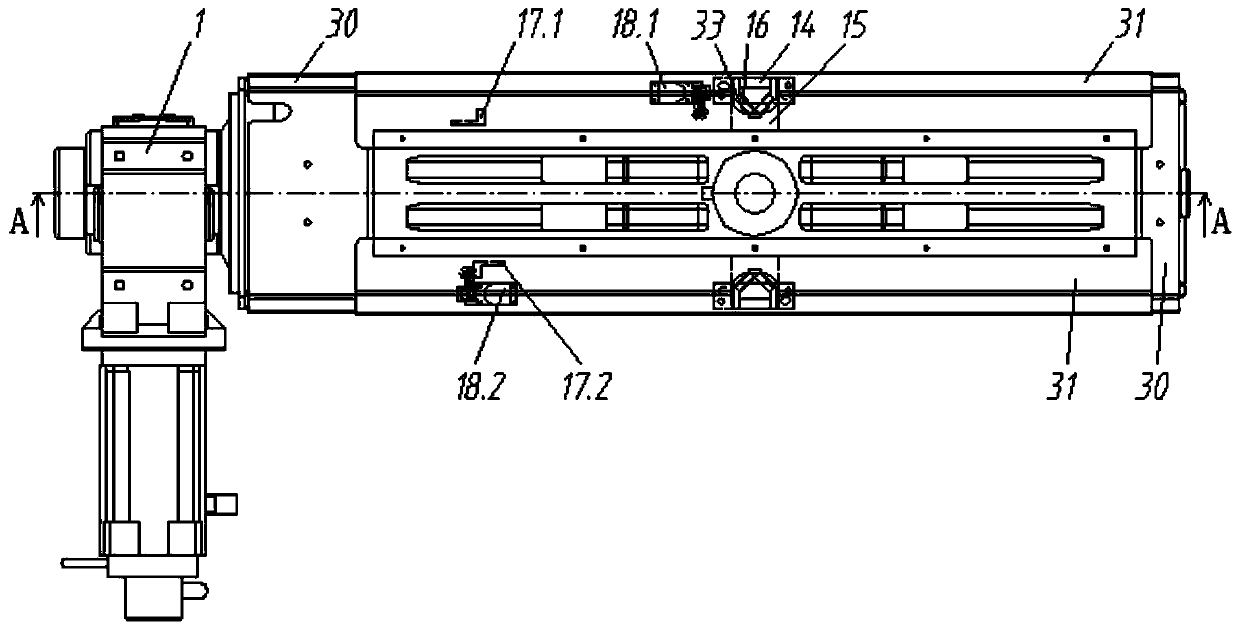

[0034] The present invention is described in detail below in conjunction with accompanying drawing:

[0035] The present invention provides a servo-driven pressing device, which includes a mounting base 5 with a U-shaped groove structure. The left end of the mounting base 5 is fixed with a servo motor 1 through a vertically fixed casting structure, and a bidirectional Ball screw nut pair 2, the left end of the lead screw in the bidirectional ball screw nut pair 2 is fixedly connected to the output shaft of the servo motor 1, the thread of the left section of the lead screw in the bidirectional ball screw nut pair 2 and the thread of the lead screw The threads on the right section rotate in the opposite direction. When the screw rotates, the two nuts in the two-way ball screw nut pair 2 separate to the left and right sides or move closer to the middle, and the two nuts in the two-way ball screw nut pair 2 are fixedly connected. One cam slider, the cam slider 3 on the left and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com