A large component igbt press-fit unit

A large-component, press-fit technology, applied in electrical components, semiconductor devices, electric solid devices, etc., can solve the problems of inconvenient pressure loading, inaccurate pressure control, lack of elasticity in the structure, and meet the requirements of structural stability and strength. , the effect of uniform dispersion and reliable press-fit, compact insulation design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

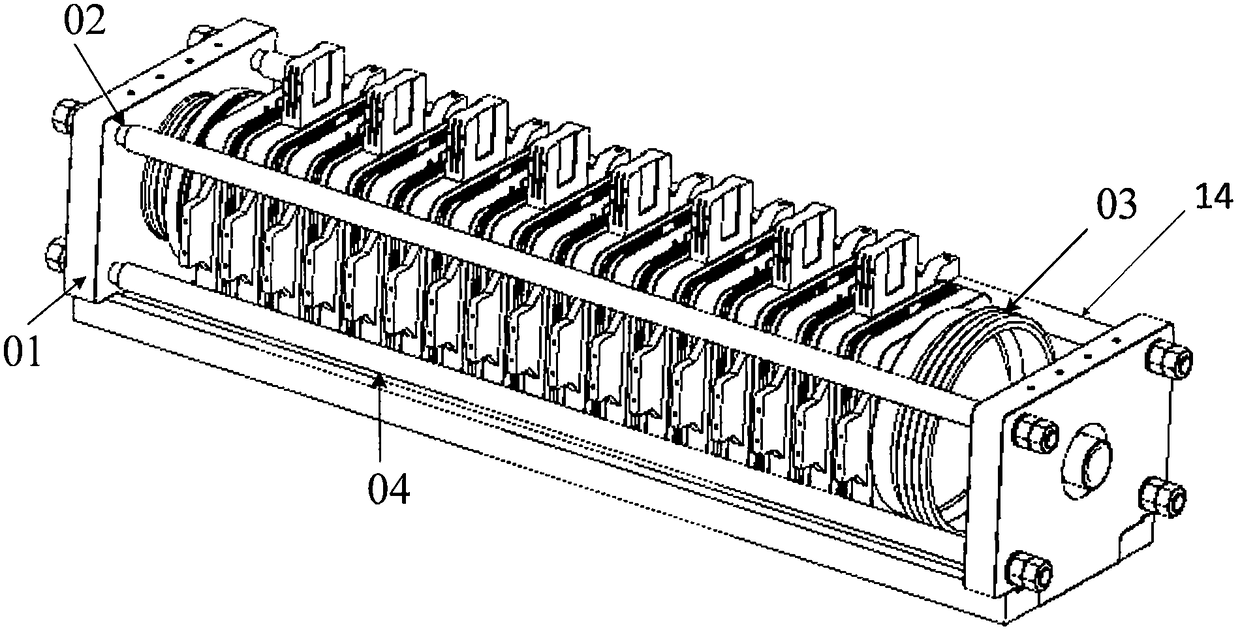

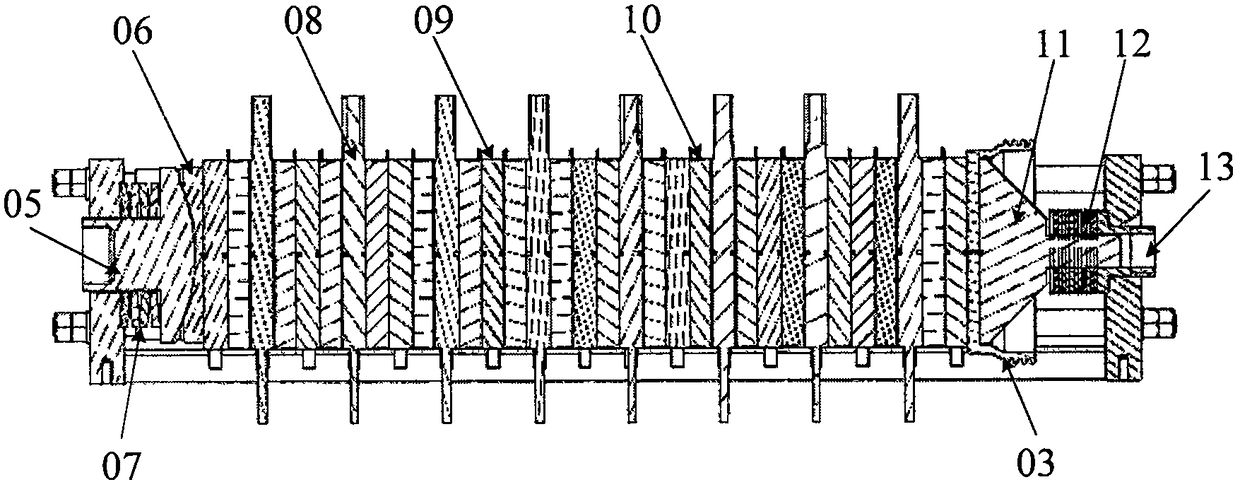

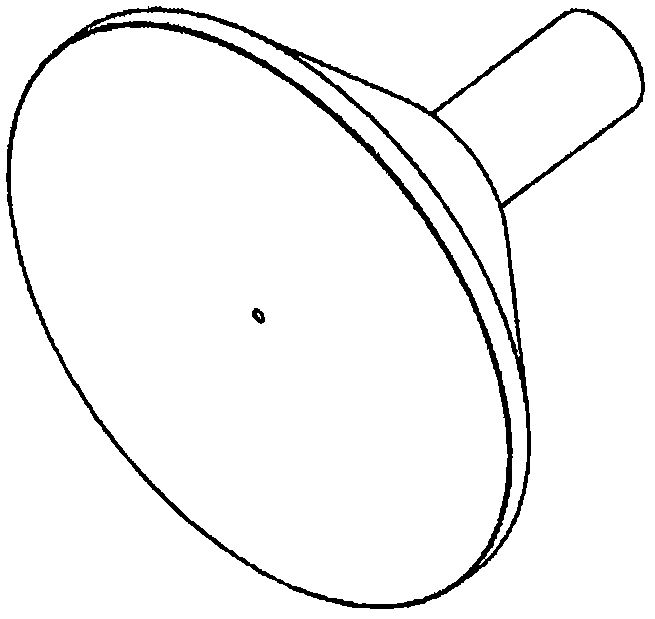

[0034]A large-component IGBT press-fit unit proposed by the present invention uses a support and fixation structure composed of metal tie rods and metal end plates as a carrier, and realizes pressure loading and pressure uniform dispersion by cooperating with press-fit stress cones and pressure self-adaptive adjustment mechanisms; The disc spring mechanism realizes long-term pressure maintenance and deformation adaptation, and the high potential isolation between the support structure and the IGBT is realized through the insulating isolation disc. In order to ensure the long-term structural stability of the IGBT during operation and avoid the adverse effects of various external impact loads on the performance of the IGBT, the press-fitting unit is designed with a precise centering mechanism to effectively protect the IGBT and meet i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com