Assembly and processing line and assembly process of left gear lever handle for automobile steering wheel

An assembly processing and steering wheel technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly accuracy and reduce defective rate, so as to reduce defective rate, avoid pollution, improve assembly accuracy and assembly quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

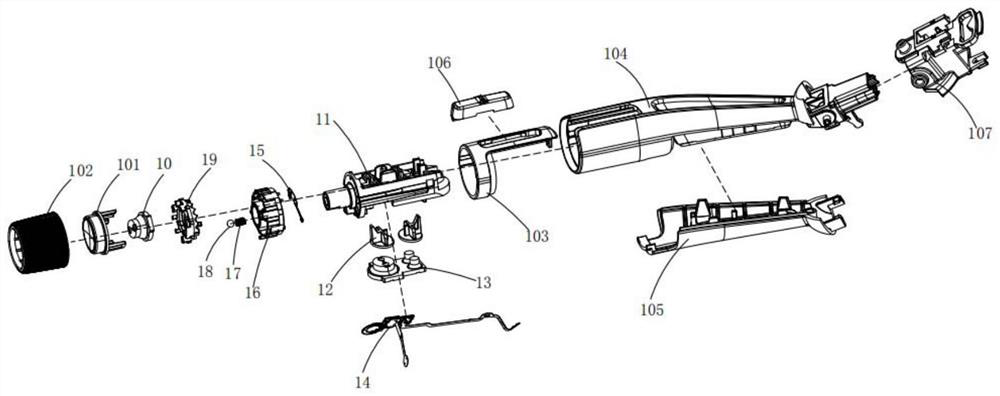

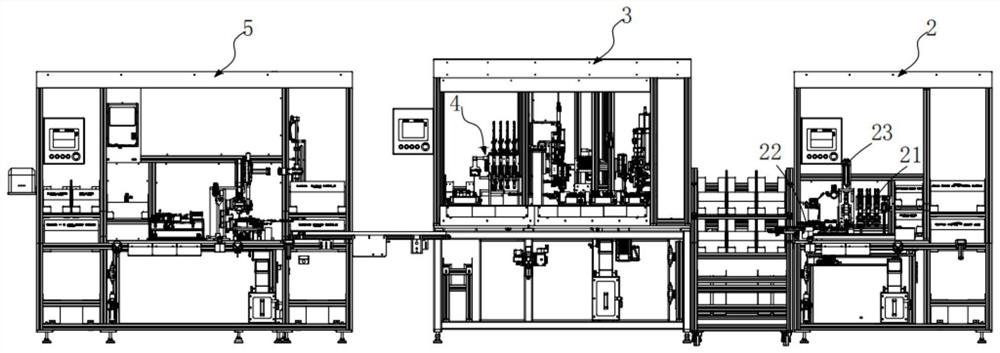

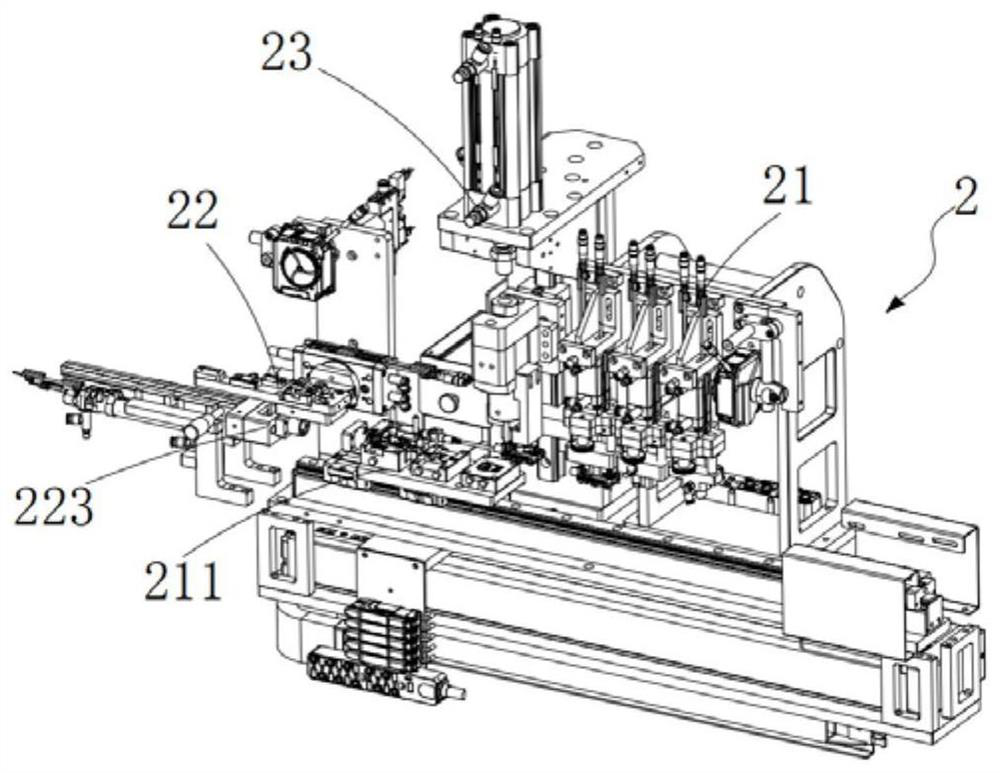

[0112] like Figure 1 to Figure 8 As shown in the figure, an assembly processing line for a left gear lever handle for an automobile steering wheel is used for assembling a left gear lever handle 1. The left gear lever handle 1 consists of a base 11, a plunger 12, a rear wiper button 13, an FFC14, a front Wiper contact piece 15, front wiper bracket 16, spring 17, steel ball 18, brake plate 19, front wiper button 10, button 101, knob 102, retaining ring 103, handle 104, handle housing 105, wiper button 106 and the rotor 107 are assembled together, and the assembly processing line for assembling the left gear lever handle 1 includes a pre-assembly assembly 2, a rotating assembly assembly 3, and an adsorption and pressing assembly that are sequentially arranged according to the assembly sequence of the left gear lever handle 1. into 4 and lock and pay the pressing assembly 5;

[0113] The pre-assembled assembly 2 includes an assembly component 21 for adsorbing the plunger 12 and...

Embodiment 2

[0185] like Figure 29 As shown, an assembly process based on the left gear lever handle assembly line for an automobile steering wheel described in Embodiment 1 includes the following steps:

[0186] Step 1, pre-assembly, place the base 11, the plunger 12 and the rear wiper button 13 on the assembly positioning seat 211 of the pre-assembly assembly 2, and the assembly positioning seat 211 slides in the horizontal direction and passes through the plunger in turn. The material hand 212, the rear wiper button grabber 213 and the lower part of the press-loading material head 214 sequentially complete the assembly work of assembling the plunger 12 and the rear wiper button 13 to the base 11;

[0187] Step 2: Install the FCC on the top. After the assembly of the plunger 12 and the rear wiper button 13 is completed, the rotary cylinder 221 on the adhesive assembly 22 drives the suction seat 222 on which the FFC 14 is adsorbed to be turned upright, and the base 11 The base 11 is dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com