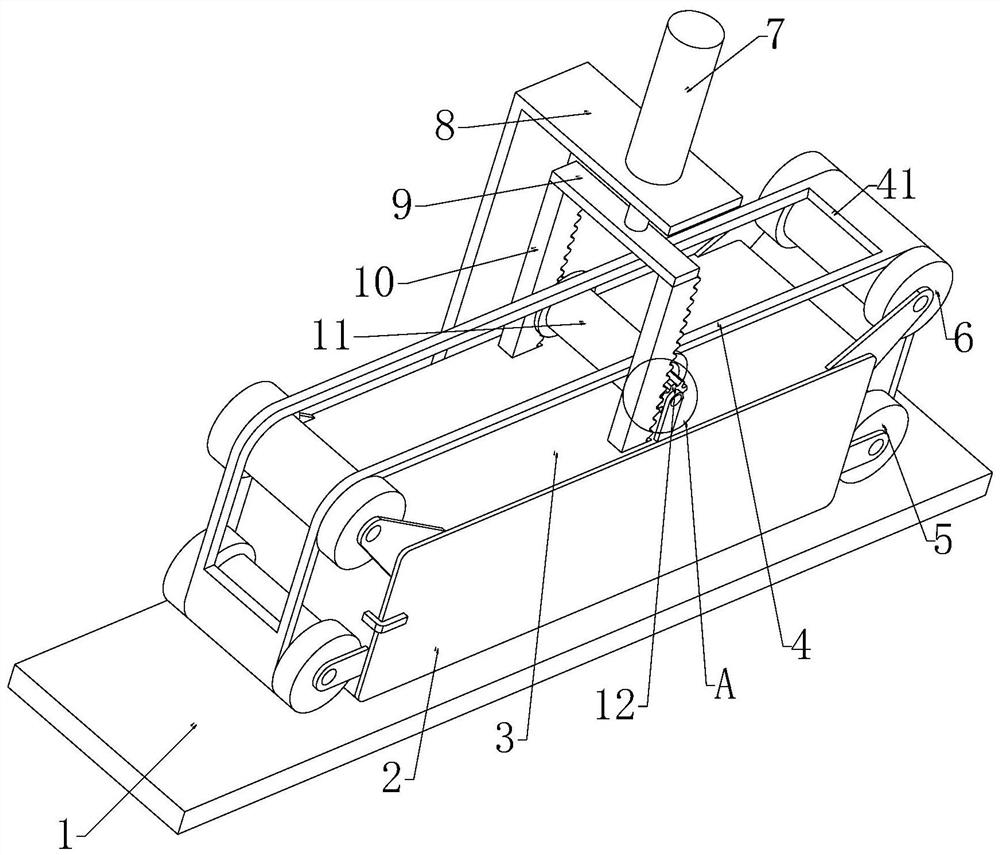

Pressing and ironing mechanism for garment production

A clothing and anti-scalding technology, applied in the field of clothing pressing, can solve problems such as easily scalded personnel, and achieve the effect of facilitating maintenance and avoiding rigid collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

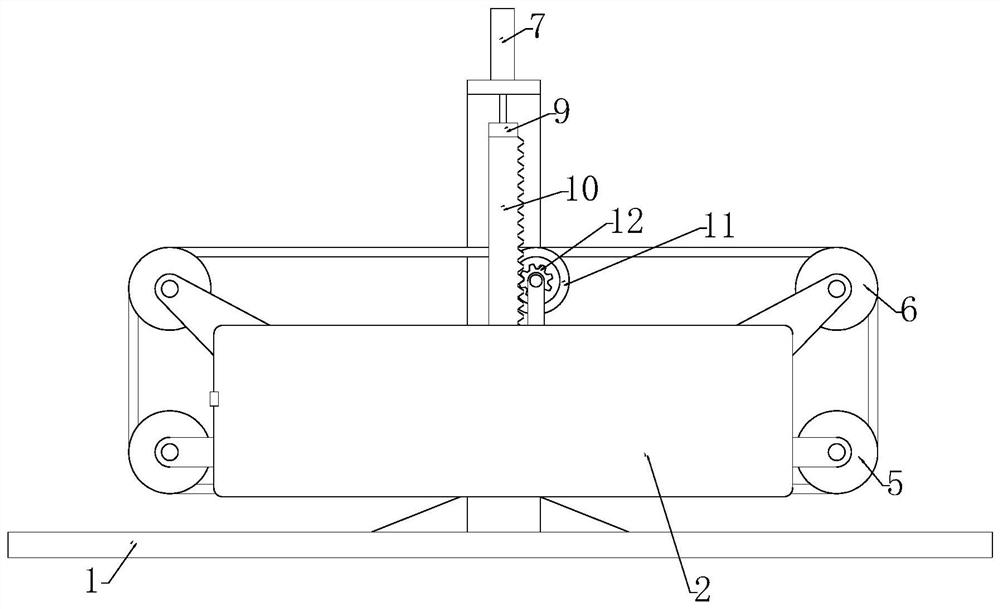

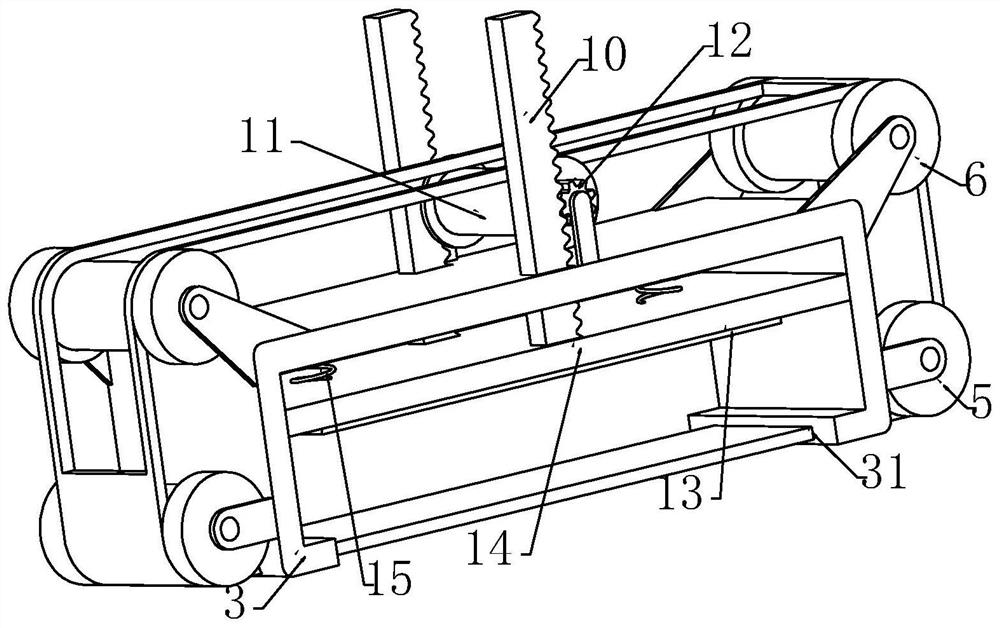

Method used

Image

Examples

specific Embodiment approach

[0031]Specific implementation method: place the clothes to be pressed on the upper end of the bottom plate 1, then connect the power supply of the electric cylinder 7, and use the switch to start the electric cylinder 7, the work of the electric cylinder 7 drives the connecting plate 9 to move downward, thereby driving the two teeth Bar 10 moves downwards, and simultaneously hollow box body 3, second support wheel 6, first support wheel 5 and the parts inside hollow box body 3 move downwards with hollow box body 3 under the action of own gravity, and hollow box body 3. When it moves down to fit the clothing on the upper end of the bottom plate 1 and compresses the clothing, the hollow box 3 stops moving downward, and the rack 10 continues to move downward to drive the heat insulation board 14 and the heating plate 13 relative to the hollow box. 3 moves downward, and at the same time the rack 10 moves downward to drive the gear 12 to rotate, and then drives the driving wheel 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com