Lid-pressing device

A capping and barrel lid technology, which is applied in packaging, transportation and packaging, bottle/container caps, etc., can solve the problems of prolonging the capping time, reducing production efficiency, and venting the barrel lid, so as to improve the pressing efficiency and reduce the Effects of running costs, ease of overlapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

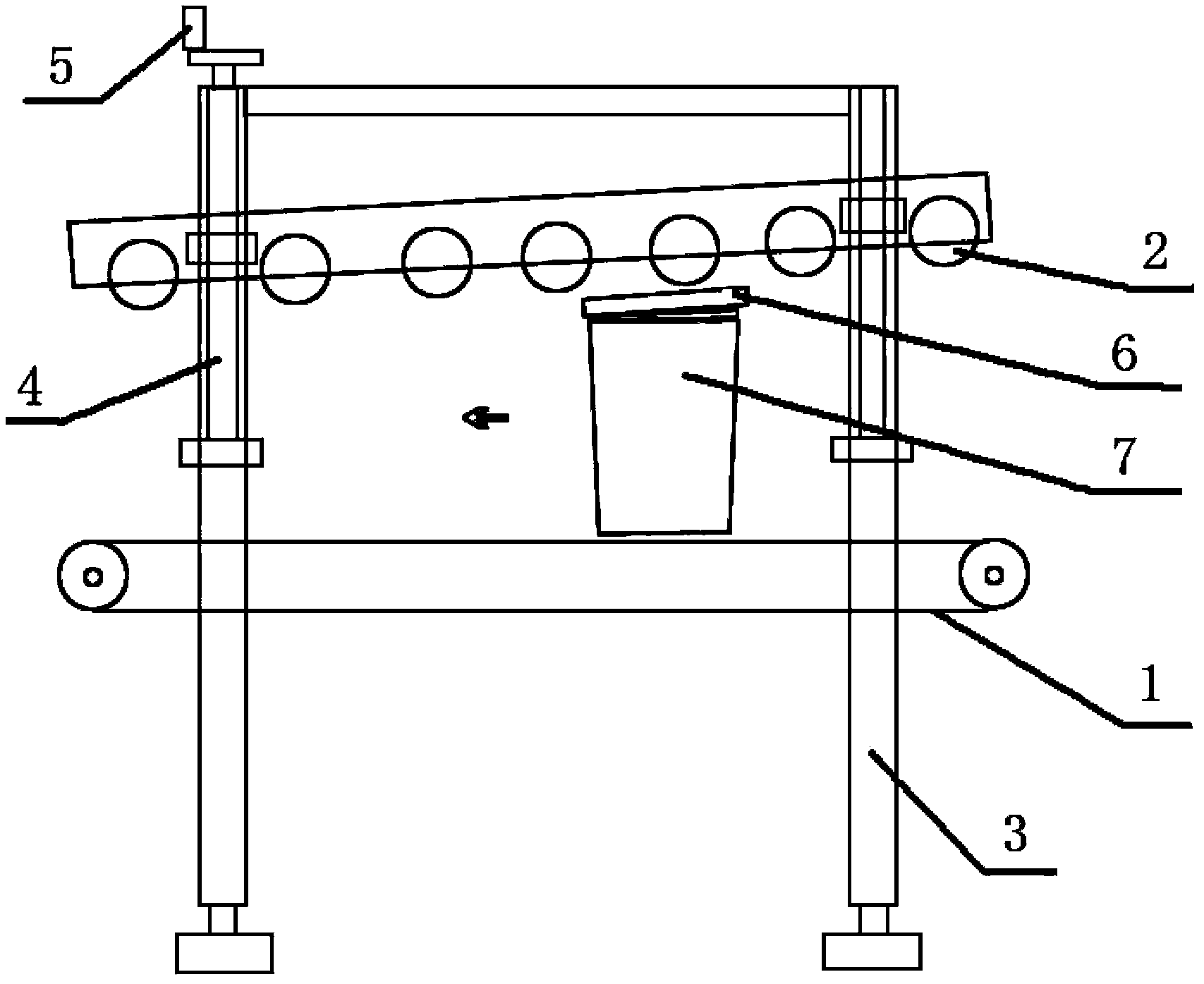

[0011] When the number of rollers N=8 and the guide angle θ=10° in conjunction with the accompanying drawings, the present invention will be further described.

[0012] Such as figure 1 As shown, the conveyor belt 1 that conveys the barrel body 7 and the roller 2 that squeezes the barrel lid 6 when the barrel body 7 and the barrel lid 6 pass through the bracket 3 above the conveyor belt 1, the roller 2 is installed on the bracket 3, and the bracket 3 straddles On the conveyor belt 1, the conveyor belt 1 is driven by a motor, and the output shaft of the motor is connected with the driving wheel through a reducer, and then the driving wheel drives the driven wheel to rotate, thereby making the conveyor belt rotate. All the rollers 2 share two pairs of brackets 3 and are arranged in a row to form a roller board. There is a guide angle θ between the conveyor belt 1 and the roller boards to allow the bucket body 7 to pass through. The brackets 3 have a lifting adjustment mechanism....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com