Flame-retardant anti-wrinkle finishing agent for fabric and preparation method and application thereof

An anti-wrinkle finishing agent and textile finishing technology, applied in the direction of textiles and papermaking, fiber treatment, fiber type, etc., can solve the problems of single function, non-obvious effect on textile flame retardancy and anti-wrinkle performance, and improve anti-wrinkle performance and anti-wrinkle effect Improve and enhance the effect of flame retardant strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

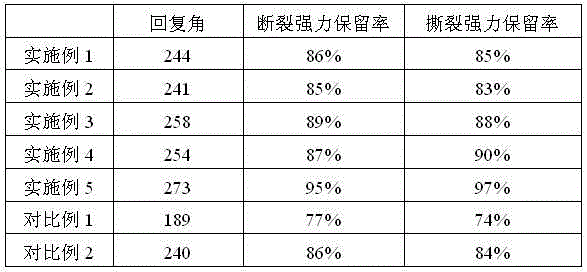

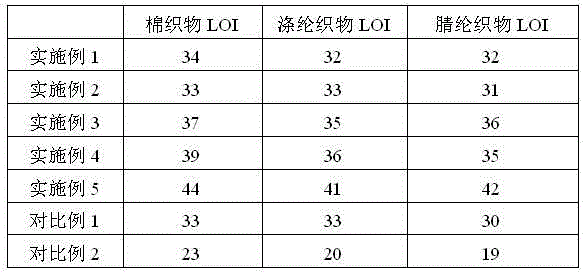

Examples

Embodiment 1

[0046] (1) Take 20Kg of propylene glycol and 400Kg of water by weight, heat the propylene glycol and water to 55°C, and after the temperature is stable, stir the propylene glycol and the propylene glycol with a magnetic stirring speed of 100rpm, and stir until uniform, and it is a mixed solution A; ( 2) Keeping the temperature constant, slowly add 15Kg of polyglycerol castorate, 20Kg of simethicone, and The ester is 13Kg, and the secondary alcohol polyoxyethylene ether is 8Kg. While adding the above-mentioned ingredients dropwise, carry out magnetic stirring at the same time, the stirring speed is still 100rpm, and stir until the above-mentioned ingredients are completely dissolved, and it is a mixed solution B; (3) Keep the temperature Still at 55°C, add 15Kg of trimethyl phosphite, 9Kg of triisopropyl phosphite, 7Kg of triisopropyl borate, and 3Kg of aminopropanol ascorbyl phosphate in the mixed solution B, and then add the above-mentioned All the ingredients are magneticall...

Embodiment 2

[0048] (1) Take 12Kg of propylene glycol and 300Kg of water by weight. Heat the propylene glycol and water to 55°C. After the temperature stabilizes, stir the propylene glycol and the propylene glycol with a magnetic stirring speed of 100rpm. 2) Keeping the temperature constant, slowly add 8Kg of polyglycerol castorate, 14Kg of simethicone, and polydimethylsiloxanol stearic acid to the mixture A in step (1) by weight. The ester is 5Kg, and the secondary alcohol polyoxyethylene ether is 4Kg. While adding the above ingredients dropwise, perform magnetic stirring at the same time, the stirring speed is still 100rpm, and stir until the above ingredients are completely dissolved, and it is a mixed solution B; (3) Keep the temperature Still be 55 ℃, add trimethyl phosphite again in the mixed solution B to be 8Kg, triisopropyl phosphite to be 4Kg, triisopropyl borate to be 4Kg, amino propanol ascorbic acid phosphate to be 7Kg, again to above-mentioned All the ingredients are magnetic...

Embodiment 3

[0050] (1) Take 14Kg of propylene glycol and 320Kg of water by weight. Heat the propylene glycol and water to 55°C. After the temperature is stable, stir the propylene glycol and the propylene glycol with a magnetic stirring speed of 100rpm. 2) Keeping the temperature constant, slowly add 10Kg of polyglycerol castorate, 18Kg of simethicone, and The ester is 7Kg, and the secondary alcohol polyoxyethylene ether is 7Kg. While adding the above ingredients dropwise, perform magnetic stirring at the same time, the stirring speed is still 100rpm, stir until the above ingredients are completely dissolved, and it is a mixed solution B; (3) Keep the temperature Still be 55 ℃, add trimethyl phosphite again in mixed solution B to be 13Kg, triisopropyl phosphite to be 8Kg, triisopropyl borate to be 5Kg, aminopropanol ascorbyl phosphate to be 6Kg, again to above-mentioned All the ingredients are magnetically stirred until all the ingredients are evenly mixed, and the flame-retardant anti-wr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com