Process for preparing 3-amino propane sulfonic acid

A technology of aminopropanesulfonic acid and sulfonation reaction, which is applied in the preparation of sulfonic acid, organic chemistry, etc., can solve the problems such as the inability to obtain a purity greater than 98%, and achieve the effects of mild reaction conditions and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

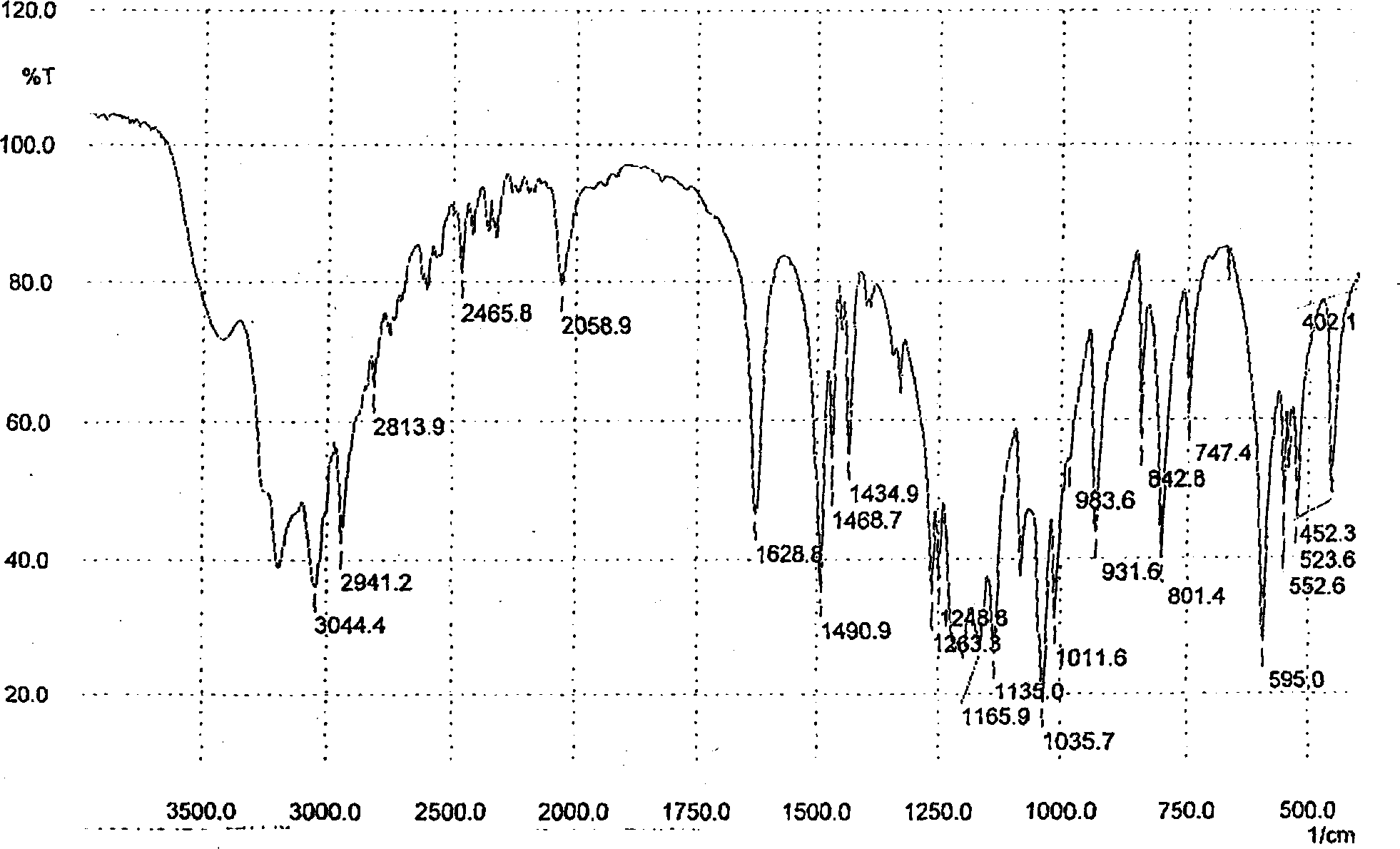

Image

Examples

Embodiment 1

[0017] Add 15g (0.2mol) of 3-aminopropanol into the reaction flask, add 20ml of concentrated hydrochloric acid and fully stir, then continue to pass in hydrogen chloride to saturation at 40-50°C, and continue to react for 4 hours. Cool to room temperature. And add 75ml of absolute ethanol to dilute, cool to 10°C or lower, a white solid precipitates out. Filter and drain to obtain the intermediate compound of γ-chlorpropanine hydrochloride. After the separation of the intermediate compound, add 10ml of water, and add 30g of Na 2 SO 3 The supersaturated solution of the supersaturated solution was refluxed for 6 hours, and the water was evaporated as much as possible under reduced pressure. After filtering while it was hot, the filtrate was adjusted to pH 6-7 with hydrochloric acid, and 15ml of absolute ethanol was added to dilute it appropriately, so as to obtain a more ideal crystal form , and then cooled to 0°C for crystallization. After filtration, 23 g of 3-aminopropanes...

Embodiment 2

[0020] Add 10 g (0.13 mol) of 3-aminopropanol to the reaction flask while stirring at 50°C and pass in hydrogen chloride until it is no longer absorbed, and react for about 4 hours. 50 ml of 95% ethanol was added to the reactant, cooled to room temperature and then filtered to obtain the intermediate compound of γ-chloralanine hydrochloride. After washing the intermediate compound with 85% ethanol solution, add 5ml of water to dissolve it, and add 20g NaHSO heated to boiling in the intermediate solution under stirring 3 After a concentrated solution, it was refluxed for another 5 hours. After the water was evaporated under reduced pressure, it was filtered while it was hot. After the filtrate was adjusted to neutrality with hydrochloric acid, 10ml of absolute ethanol was added for appropriate dilution, and cooled to 0°C for crystallization. Filtrate to obtain 15g of 3-aminopropanesulfonic acid. During recrystallization, heat to reflux with 200ml of 85% ethanol, cool and crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com