Preparation method of D-panthenol

A technology of panthenol and aminopropanol, which is applied in the field of D-panthenol preparation, can solve the problems of poor quality of D-panthenol, high reaction requirements, and high quality requirements, etc., and achieve less impurities, high purity, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

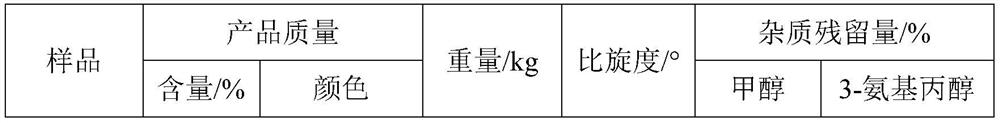

Examples

Embodiment 1

[0032] A kind of preparation method of D-panthenol is as follows:

[0033] (1) 1310 kg of D-pantoolactone was dissolved in 1500L of methanol, 750 kg of 3-aminopropanol was added to the reaction kettle, the temperature was raised to 28° C. for acylation reaction for 6 hours, and a mixed solution containing D-panthenol was obtained;

[0034] (2) The mixed solution is filtered through a resin column (filled with adsorption ester resin FB-02), and the filtered solution enters a water-bath scraper concentrator to recover methanol under reduced pressure. The temperature of the water bath is 65° C. to obtain D-panthenol.

Embodiment 2-3

[0036] The difference from Example 1 is that in this example, the molar ratios of D-pantolactone and 3-aminopropanol are 1.01:1 (Example 2) and 1.05:1 (Example 3).

Embodiment 4

[0038] A kind of preparation method of D-panthenol is as follows:

[0039] (1) 1306 kg of D-pantoolactone was dissolved in 1500L of methanol, 750 kg of 3-aminopropanol was added to the reaction kettle, the temperature was raised to 25° C. for acylation reaction for 8 hours, and a mixed solution containing D-panthenol was obtained;

[0040] (2) The mixed solution is filtered through a resin column, and the filtrate enters a water-bath scraper concentrator for methanol recovery. The temperature of the water bath is 68° C., and the methanol is recovered under reduced pressure to obtain D-panthenol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com