Catalyst, method for preparing 3-aminopropanol through catalyst, and adopted system

A technology of aminopropanol and heterogeneous catalysts, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, and preparation of organic compounds. It can solve problems such as low activity, poor catalyst stability, and harsh reaction conditions, and achieve process operation. Simple, wide response pressure range, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

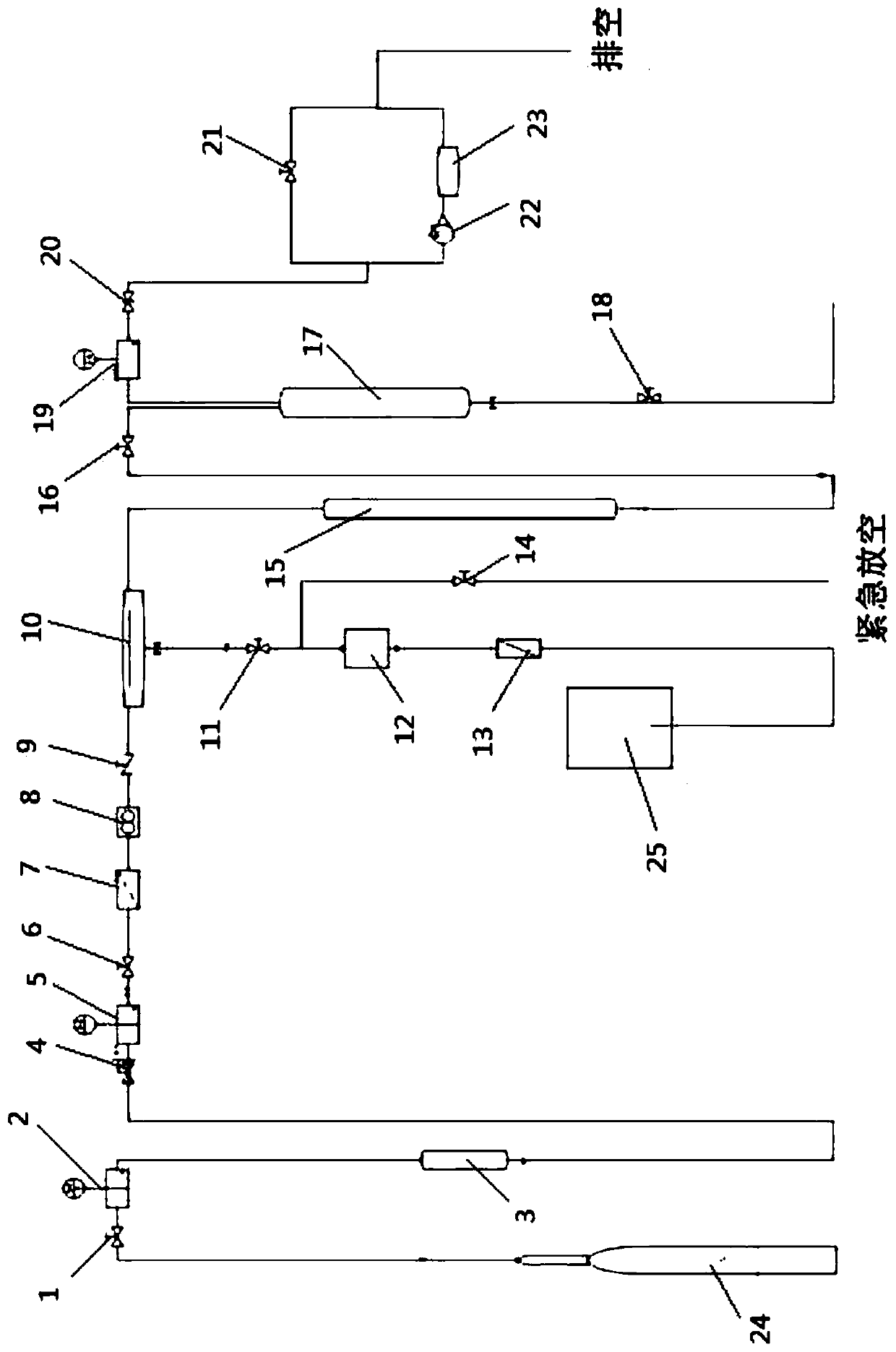

[0035] Preparation of 3-aminopropanol:

[0036] The product obtained in the present invention is analyzed using Agilent7890B, DB-35 capillary chromatographic column, and FID detector.

Embodiment 1

[0038] Weigh the above 20Ni-3Re / SiO 2 Catalyst 2.6g (approximately 5ml) is loaded into a fixed-bed reactor. Before use, the catalyst is activated by hydrogenation treatment. The activation conditions are: temperature T=390°C; pressure P is 0.3MPa, gas volume space velocity GHSV=1500h -1 , The reduction time is 6 hours. When the temperature in the reactor naturally drops to 100°C, the pressure is increased to 8MPa, and the system is stabilized. Mix liquid ammonia and 3-hydroxypropionitrile with a molar ratio of 5:1, then put the mixed liquid into the mixer 10 through the high-pressure pump 12 after the fixed bed reaction system is stable, and adjust the liquid of 3-hydroxypropionitrile The mass space velocity is 1.0 3-hydroxypropionitrile g / catalyst g h, the mol ratio of hydrogen and 3-hydroxypropionitrile in the reaction system is 2.0:1, reacts, and the reaction time is 48 hours, sampled by collection tank 17 Analysis by gas chromatography. 3-Hydroxypropionitrile hydrogena...

Embodiment 2

[0040] Weigh the above 20Ni-3Re / SiO 2 Catalyst 2.6g (approximately 5ml) is loaded into a fixed-bed reactor. Before use, the catalyst is activated by hydrogenation treatment. The activation conditions are: temperature T=390°C; pressure P is 0.3MPa, gas volume space velocity GHSV=1500h -1 , The reduction time is 6 hours. When the temperature in the reactor naturally drops to 100°C, the pressure is increased to 8MPa, and the system is stabilized. Mix liquid ammonia and 3-hydroxypropionitrile with a molar ratio of 5:1, then put the mixed liquid into the mixer 10 through the high-pressure pump 12 after the fixed bed reaction system is stable, and adjust the liquid of 3-hydroxypropionitrile Mass space velocity is 1.0 3-hydroxypropionitrile g / catalyst g h, the mol ratio of hydrogen and 3-hydroxypropionitrile in the reaction system is 2.2:1, reacts, and the reaction time is 48 hours, is sampled by collection tank 17 Analysis by gas chromatography. 3-Hydroxypropionitrile is subject...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com