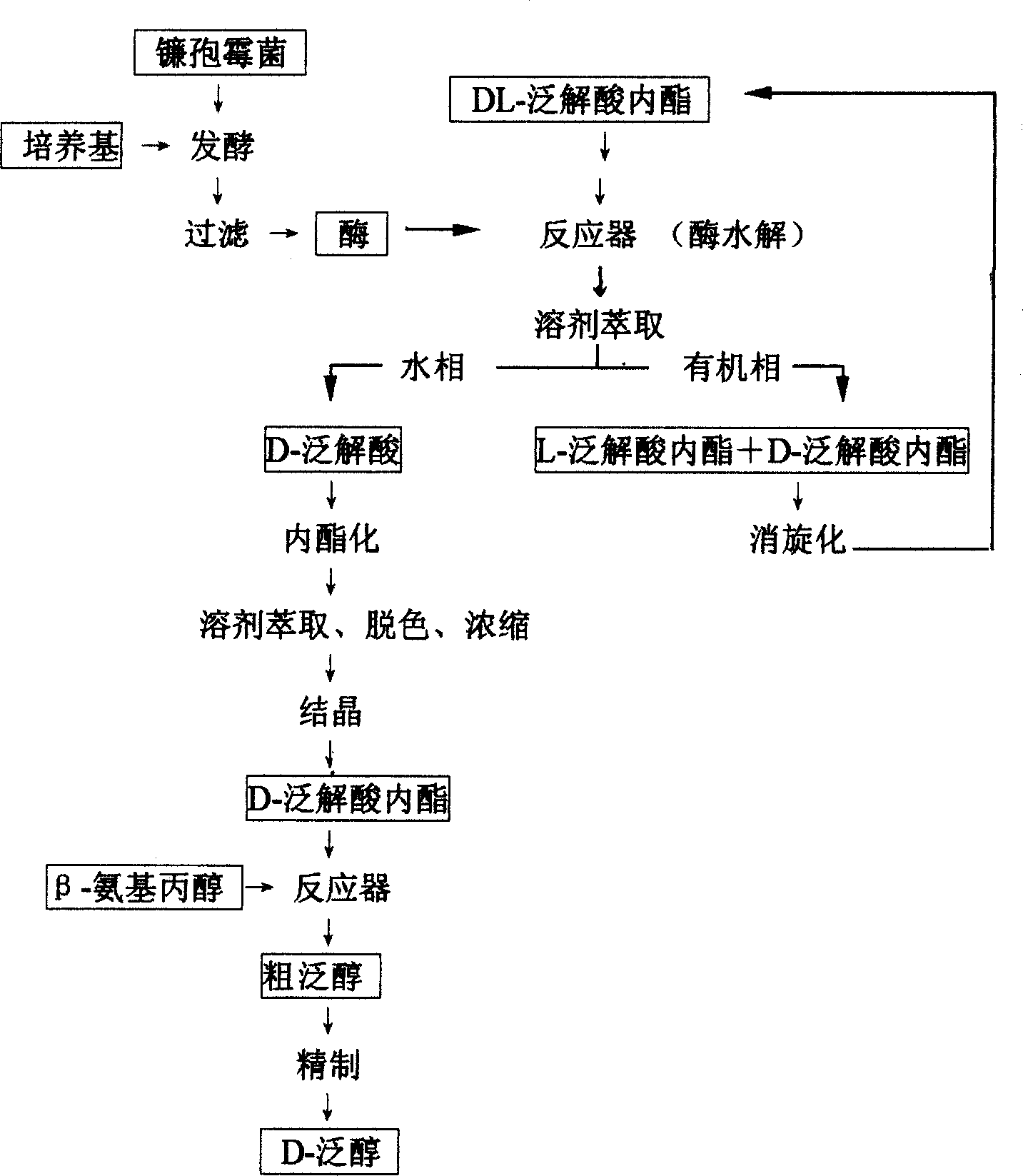

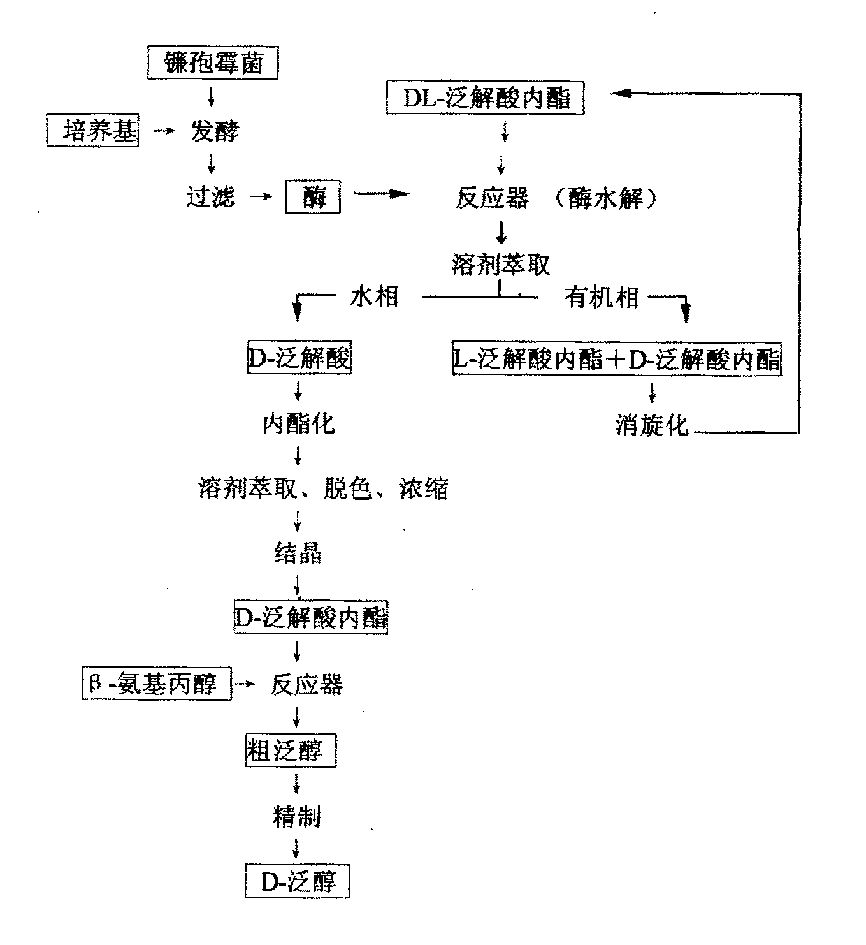

Method for preparing D-pantothenic alcohol by using microbial enzyme method

A microbial enzyme and microbial technology, applied in the field of microbial enzymatic preparation of D-panthenol, can solve the problems of many operation steps, low recovery rate of resolving agent, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Slant culture: the medium is 100ml of potato juice (20%), 2g of glucose, 2g of agar, pH6.5, sterilized at 121°C for 20 minutes, cooled and inoculated after sterilization, and the strain is Fusarium moniliforme (Fusarium moniliforme) SW- 902 CGMCC No.0536, cultured at 25°C for 5-7 days, used as slant activated seeds.

[0015] Enzyme production culture: the medium is 3% glycerol, 0.5% peptone, 0.5% yeast extract, 0.5% corn steep liquor, pH 6.0, the liquid volume is 500ml, 100ml of the triangular bottle, sterilized at 121°C for 20 minutes, and sterilized Afterwards, cool and inoculate the slant seeds, cultivate at 28° C. for 1 to 5 days, filter or centrifuge the fermented liquid, and obtain wet thallus (D-pantolactone hydrolase) as an enzyme source.

[0016] DL-pantolactone prepared by chemical synthesis, with 50mmol CaCl 2 The aqueous solution is prepared as a substrate with a concentration of 30%; the amount of enzyme added is 0.3U / g pantolactone, placed on a shaking ta...

Embodiment 2

[0018] In the reactor, add 2,000Kg of anhydrous methanol and 750Kg of β-aminopropanol, start stirring, put in 1,300Kg of D-pantolactone obtained by the method in Example 1, keep at 40-50°C, react for 24hrs, and depressurize Concentrate until no methanol is distilled off, discharge, and obtain 2,051Kg of colorless transparent viscous liquid D-panthenol, the mol yield to the input D-pantolactone is 99.93%, and the measured specific rotation is [α] D 20 =+30.1°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com